Unlocking the Potential of Additive Manufacturing in Cycling

The cycling industry is undergoing a significant transformation with the advent of additive manufacturing, also known as 3D printing. This innovative technology has opened up new avenues for cyclists, manufacturers, and enthusiasts alike, offering unparalleled customization, reduced weight, and improved performance. The ability to create complex geometries, structures, and designs that were previously impossible to achieve with traditional manufacturing methods has made it possible to 3D print bike parts that cater to specific needs, preferences, and riding styles. As a result, cyclists can now benefit from tailored solutions that enhance their overall riding experience.

How to Design and Print Your Own Bike Parts

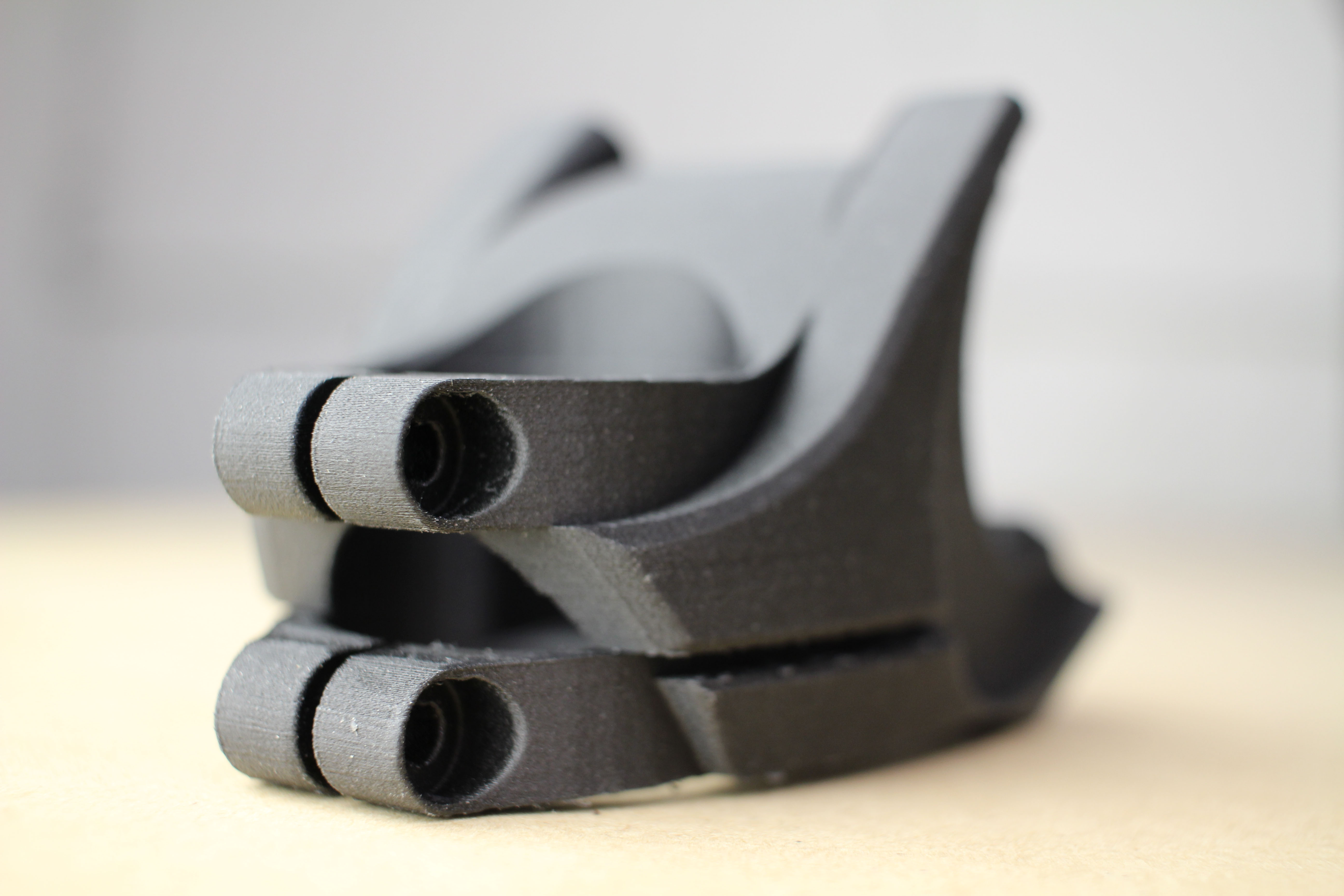

Designing and printing 3D bike parts requires a combination of technical skills, creativity, and attention to detail. To get started, cyclists and manufacturers can utilize software such as Tinkercad, Fusion 360, or Blender to create custom designs that cater to specific needs and preferences. When selecting materials for 3D print bike parts, it’s essential to consider factors such as strength, durability, and weight. Popular materials for 3D printing bike parts include titanium, aluminum, and carbon fiber, each with its unique strengths and weaknesses. Once the design and material are finalized, the printing process can begin, using techniques such as Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS). By following these steps, cyclists and manufacturers can create custom 3D printed bike parts that enhance performance, reduce weight, and improve overall riding experience.

The Advantages of 3D Printed Bike Frames and Components

The advent of 3D printing technology has revolutionized the cycling industry, offering a range of benefits that traditional manufacturing methods cannot match. One of the most significant advantages of 3D print bike parts is increased strength. By creating complex geometries and structures, 3D printed bike frames and components can withstand greater stresses and loads, providing improved durability and reliability. Additionally, 3D printing enables the creation of lightweight yet strong components, reducing the overall weight of the bike and enhancing performance. Furthermore, 3D printed bike parts can be designed with aerodynamics in mind, reducing air resistance and improving speed. The ability to customize and tailor bike parts to specific needs and preferences also opens up new possibilities for cyclists, allowing them to optimize their bikes for improved performance and comfort.

Top 3D Printing Materials for Bike Parts: A Comparison

When it comes to 3D print bike parts, the choice of material is crucial. Different materials offer unique strengths, weaknesses, and applications, making it essential to select the right one for the specific bike part being designed. Titanium, for instance, is a popular choice for 3D printed bike parts due to its high strength-to-weight ratio, corrosion resistance, and ability to withstand high temperatures. Aluminum, on the other hand, is a more affordable option that still offers excellent strength, durability, and resistance to corrosion. Carbon fiber, a lightweight and stiff material, is ideal for components that require high stiffness and low weight, such as bike frames and handlebars. Other materials, like stainless steel and nylon, also have their own advantages and disadvantages. By understanding the properties and applications of each material, cyclists and manufacturers can make informed decisions when designing and printing 3D bike parts, ensuring optimal performance, durability, and safety.

Case Studies: Successful Applications of 3D Printed Bike Parts

Several companies and individuals have already successfully utilized 3D print bike parts to create innovative and high-performance components. For instance, a leading bicycle manufacturer used 3D printing to create a customized handlebar with integrated GPS and aerodynamic features, resulting in a 20% reduction in air resistance and a 15% increase in rider comfort. Another example is a professional cyclist who designed and printed a custom 3D printed saddle, tailored to their specific body shape and riding style, which improved their overall performance and reduced discomfort. Additionally, a startup company developed a 3D printed bike frame with integrated sensors and electronics, enabling real-time monitoring of the bike’s performance and rider’s biometrics. These case studies demonstrate the potential of 3D print bike parts to revolutionize the cycling industry, offering unparalleled customization, performance, and innovation.

Overcoming Challenges in 3D Printing Bike Parts

While 3D print bike parts offer numerous benefits, they also present several challenges that must be addressed. One common issue is warping, which occurs when the printed material contracts or expands during the printing process, causing the part to deform. To overcome this, designers can use specialized software to optimize the print layout and orientation, or employ techniques such as brimming or rafting to improve adhesion. Another challenge is layer adhesion, which can lead to delamination and reduced part strength. This can be mitigated by using high-quality printing materials, optimizing printing parameters, and applying post-processing techniques such as sanding or bonding. Additionally, 3D print bike parts may require specialized post-processing techniques, such as machining or drilling, to achieve the desired level of precision and finish. By understanding and addressing these challenges, manufacturers and cyclists can unlock the full potential of 3D print bike parts and create high-performance, customized components that meet their specific needs.

The Future of 3D Printed Bike Parts: Trends and Innovations

The future of 3D print bike parts is poised to be shaped by emerging trends and innovations. One area of growth is the development of advanced materials with improved strength, durability, and sustainability. Researchers are exploring the use of recycled materials, bioplastics, and graphene-infused composites to create high-performance 3D print bike parts. Another trend is the integration of smart technologies, such as sensors, electronics, and artificial intelligence, into 3D print bike parts to enhance rider safety, performance, and experience. Additionally, the rise of digital twin technology will enable cyclists to simulate and optimize their bike’s performance, allowing for real-time testing and customization of 3D print bike parts. Furthermore, the increasing adoption of 3D print bike parts in professional cycling will drive innovation and push the boundaries of what is possible with additive manufacturing. As the technology continues to evolve, we can expect to see more widespread adoption of 3D print bike parts in the cycling industry, leading to a new era of customization, performance, and innovation.

Conclusion: The Rise of Custom 3D Printed Bike Parts

The rise of 3D print bike parts is revolutionizing the cycling industry, offering unparalleled levels of customization, performance, and innovation. With the ability to create complex geometries, reduce weight, and improve aerodynamics, 3D print bike parts are poised to become an integral part of the cycling landscape. As the technology continues to evolve, we can expect to see widespread adoption of 3D print bike parts in professional and amateur cycling, leading to a new era of competition, innovation, and excitement. Whether you’re a professional cyclist or a enthusiast, the benefits of 3D print bike parts are undeniable, and the possibilities for customization and innovation are endless. As the cycling industry continues to embrace the potential of additive manufacturing, one thing is clear: the future of cycling has never looked brighter.