Identifying the Problem: Shifter, Cable, or Derailleur?

Smooth gear shifting is crucial for an enjoyable cycling experience, and understanding the components involved is the first step in learning how to fix bicycle gears shifter issues. Three main parts work together: the shifter, the cable, and the derailleur. The shifter, located on your handlebars, is what you use to select gears. It sends a signal via the cable to the derailleur, a mechanism near the rear wheel that moves the chain between the cogs (cassette) or chainrings (on the crankset). Problems with any of these components can cause shifting difficulties. A malfunctioning shifter might not click properly or might feel spongy, preventing gear changes. You might need to learn how to fix bicycle gears shifter in this case. A damaged or incorrectly adjusted cable, often visible as fraying or kinking, can result in inconsistent shifting or a complete lack of response. A sticky or broken cable hinders the transmission of the shifter’s command to the derailleur. Visual inspection of the cable is necessary; a frayed cable definitely needs replacing and is a key part of knowing how to fix bicycle gears shifter. Finally, a derailleur problem might manifest as the chain falling off the cassette, skipping gears, or generally sluggish movement. A bent derailleur hanger, the part attaching the derailleur to the bike frame, can cause significant shifting issues. Examining each component and looking for visible damage is the initial diagnostic step.

To effectively diagnose the source of shifting problems, a methodical approach is recommended. Begin by carefully checking the shifter. Does it move freely, clicking distinctly into each gear position? A stiff or unresponsive shifter could indicate internal problems needing professional attention. Next, inspect the cable housing for kinks, and the cable itself for fraying or corrosion – common problems preventing smooth gear changes, and important to know when learning how to fix bicycle gears shifter. Carefully run your fingers along the length of the cable. If the cable is excessively stiff, replacing it should be a priority in learning how to fix bicycle gears shifter. Then, visually examine the derailleur. Look for signs of damage such as bent hanger or damage to the derailleur’s body. If the derailleur itself moves freely when manually manipulated, the problem likely lies elsewhere. However, if the derailleur is stiff or does not move smoothly, it could indicate a more serious mechanical issue. These initial checks often pinpoint the source of the problem. Remember, accurate identification of the problem is essential to fixing it efficiently.

Understanding the symptoms associated with each component is vital for effective troubleshooting. A lack of clicking from the shifter points to a shifter issue or a problem with the cable’s connection. If the shifter clicks but the gears don’t change, the cable or derailleur is likely at fault. If the gears sometimes shift correctly and sometimes not, the problem could be a partially frayed cable, a faulty shifter, or issues with the derailleur’s adjustment. Learning how to fix bicycle gears shifter involves careful observation and systematic checking. Knowing the differences between a stiff shifter, a broken cable, or a misaligned derailleur is crucial to knowing what to fix. For many common problems, addressing a frayed or broken cable is a simple repair to ensure your gear shifting is back in order. A visual inspection, using diagrams or illustrations to compare your bike’s components, will aid in quickly identifying the source of the issue. This will greatly assist you in knowing how to fix bicycle gears shifter.

How to Adjust Your Bicycle’s Gear Cables: A Step-by-Step Guide

Adjusting your bicycle’s gear cables is a crucial step in learning how to fix bicycle gears shifter issues and ensuring smooth shifting. This process involves fine-tuning the cable tension at both the shifter and the derailleur. Begin by locating the barrel adjuster on your shifter. This is a small, rotating knob usually located near the shifter lever. Different shifters have different barrel adjuster designs; some are integrated into the shifter body, while others are separate components. Turning the barrel adjuster clockwise will tighten the cable, causing the gears to shift towards the higher gears (e.g., smaller cogs in the rear cassette). Conversely, turning it counter-clockwise will loosen the cable, shifting towards the lower gears (larger cogs). Make small adjustments – a quarter or half turn at a time – to avoid over-adjusting. After each adjustment, test the shifting by pedaling and shifting through the gears. Listen for any clicking sounds, which may indicate problems with how to fix bicycle gears shifter that needs further tuning. Observe if the chain moves smoothly between cogs without skipping or hesitation. Repeat this process of small adjustments and testing until you achieve smooth and precise shifting. Remember, learning how to fix bicycle gears shifter often involves patience and careful observation.

Next, proceed to adjust the cable tension at the derailleur. The derailleur’s cable clamp usually has a small bolt or screw for tension adjustment. This bolt is often located near the cable housing entry point on the derailleur. Tightening this bolt increases cable tension, while loosening it decreases it. Again, proceed incrementally, making small adjustments and testing the shifting after each change. Pay attention to whether the derailleur moves freely and efficiently. While adjusting the derailleur cable tension, you may also need to adjust the limit screws. These screws control the range of motion for the derailleur, preventing it from overshifting and potentially damaging the derailleur or chain. The high limit screw prevents the derailleur from shifting to the smallest cog, while the low limit screw prevents it from shifting to the largest cog. Proper limit screw adjustment is critical in understanding how to fix bicycle gears shifter and avoiding damage. These adjustments may be required in conjunction with the barrel adjuster and cable tension adjustments. The precise location and adjustment method for limit screws varies depending on the derailleur model, so consult your bicycle’s instruction manual or an online guide specific to your derailleur for more detailed instructions on how to fix bicycle gears shifter effectively.

Understanding how to fix bicycle gears shifter requires a combined approach of adjusting the barrel adjuster on the shifter for initial cable tension and using the derailleur’s cable clamp and limit screws for fine-tuning. Remember that the process of how to fix bicycle gears shifter involves making small, incremental adjustments and frequently testing the shifting performance to achieve optimal results. It’s important to note that significant shifting problems might indicate more serious issues, such as a bent derailleur hanger or a worn-out cable, which may require professional attention or component replacement. However, minor adjustments to cable tension using the methods described above can often solve common shifting problems and optimize your bike’s gear shifting performance, ultimately enhancing your riding experience. Learning how to fix bicycle gears shifter efficiently can save you time and money while extending your bike’s lifespan.

Fixing a Sticking or Broken Gear Cable

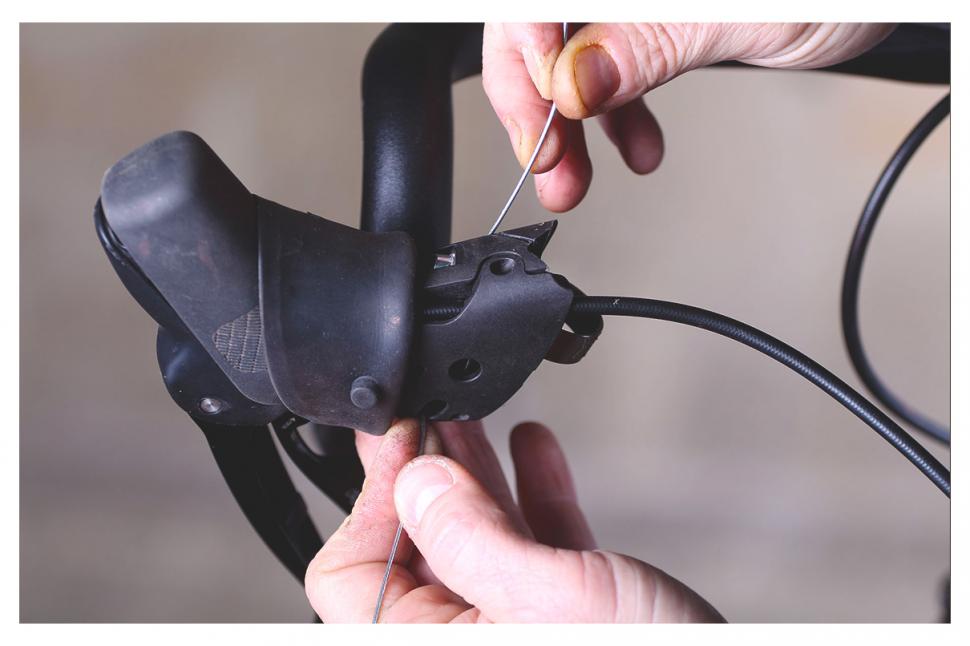

Replacing a gear cable is a crucial skill for maintaining smooth shifting on a bicycle. A frayed or broken cable can significantly impede gear changes, making it difficult and frustrating to ride. The process begins with carefully removing the old cable. To do this, first, shift the gears to the position that provides the most slack in the cable, typically the highest gear for the rear derailleur and the smallest chainring for the front. Next, using appropriate tools, usually an Allen key or small pliers, loosen the cable clamp at the derailleur. Once the cable is detached, carefully remove it from the shifter by pulling it through its housing. Pay close attention to the routing of the old cable; taking photos or making notes can be helpful for correctly installing the new one. When fitting the new cable, it’s vital to use the correct type of cable and housing for your bike’s shifting system. Incorrect components can lead to poor performance and premature wear. Begin by threading the new cable through the shifter mechanism, ensuring it follows the same path as the old one. Then, feed the cable through the housing, carefully guiding it around any bends in the frame. It’s important to ensure the housing is correctly seated in its ferrules to prevent friction. Once the cable reaches the derailleur, pull it taut with pliers and tighten the clamp. It is important to check the shifting and barrel adjusters after installation; this ensures the cable tension is correct and the indexing works effectively. Knowing how to fix bicycle gears shifter issues involves understanding this step.

Securing the cable correctly at both the shifter and derailleur is paramount to optimal shifting. After tightening the cable clamp at the derailleur, trim any excess cable with wire cutters, leaving a small tail for future adjustments. It is also crucial to ensure that the cable end is secured, using a cable end cap to prevent fraying. Incorrectly secured cables can fray and also cause damage or interfere with components and are essential to address when learning how to fix bicycle gears shifter problems. Double-check that the cable housing is correctly seated in all its ferrules, and that there are no kinks or sharp bends. In some cases, especially with older bikes or internally routed cables, it may be necessary to use a specific cable routing tool to aid in feeding the cable through the frame. Once you have verified the cable is properly routed and secured, shift through all gears to confirm smooth operation. If you encounter resistance or poor shifting, it is important to readjust tension by using the barrel adjuster at the shifter. Small adjustments can make a big difference. Remember, a well-installed cable is crucial for a bike’s performance, and it is a cornerstone skill when learning how to fix bicycle gears shifter issues.

Troubleshooting Your Rear Derailleur

The rear derailleur is frequently the culprit when bicycle gears shift poorly. A critical first step in determining how to fix bicycle gears shifter issues involves examining the derailleur hanger, which is the part that connects the derailleur to the bike frame. A bent derailleur hanger is a common problem, often resulting from accidental impacts. Visually inspect the hanger from behind the bike to check for any misalignment, noting if it’s leaning to one side or if the derailleur cage appears twisted. Even a slight bend can significantly impact shifting precision. Further inspection should involve assessing the derailleur cage and the parallelogram mechanism for any signs of damage or bending. Sometimes, the damage isn’t immediately obvious, so a careful examination is needed. Another key aspect of rear derailleur troubleshooting involves understanding the limit screws. These small screws, typically marked with an ‘H’ for high gear and an ‘L’ for low gear, dictate the range of derailleur movement, preventing it from shifting the chain off the cassette. Incorrectly set limit screws are among the common causes of poor shifting, chain drops and noise. An improper adjustment can cause the chain to overshoot the smallest or largest cog, potentially damaging the bike or causing the chain to jam between the frame and the cassette. Diagrams showing the exact location of the limit screws on the derailleur body are useful for visual guidance in determining how to fix bicycle gears shifter performance.

Adjusting the limit screws is a precise process and usually requires a small Phillips head screwdriver. The ‘H’ screw limits the derailleur’s movement to the smallest cog, while the ‘L’ screw controls movement towards the largest cog on the cassette. To adjust the ‘H’ screw, shift the chain onto the smallest cog and then observe the derailleur’s alignment. If it’s over-shifting or the chain is struggling to move onto this cog, slight adjustments to the ‘H’ screw might be needed. Clockwise rotation tightens the limit, preventing the derailleur from moving too far outwards, while counterclockwise rotation loosens it. Similarly, for the ‘L’ screw, shift the chain onto the largest cog and observe if the derailleur is moving correctly. The goal is to align the derailleur directly under the cogs to ensure smooth and precise shifts. When addressing how to fix bicycle gears shifter problems with a bent hanger, you should consider whether a repair can be attempted. Minor bends might be straightened using a derailleur alignment tool, however more severe bends will likely require a complete hanger replacement. Attempting to bend the hanger back without the proper tool can cause it to weaken and potentially break, which is why taking it to a professional mechanic might be a good choice in some cases.

Proper limit screw adjustment is crucial for optimal gear performance. This ensures that the rear derailleur is positioned correctly to shift the chain across the full range of the cassette without overshooting or undershooting. The alignment must be perfect, with the derailleur situated directly underneath each cog as it shifts through the gears. If after adjustments the issue persists, the derailleur’s pivot points should also be checked for smooth movement and to see if there’s a buildup of dirt or grime that could be preventing proper operation. These areas often get overlooked, yet maintaining clean pivot points and lightly lubricating them can improve overall shifting performance. Ultimately, when it comes to how to fix bicycle gears shifter problems related to the rear derailleur, a systematic approach of inspection, limit screw adjustment, and potentially hanger repair will produce the best results and guarantee smoother gear changes.

Fine-Tuning Your Front Derailleur

The front derailleur plays a crucial role in shifting the chain between the chainrings, influencing how efficiently you can climb hills or accelerate on flat surfaces. Understanding its operation and how to adjust it is key to ensuring smooth gear changes. The front derailleur, unlike its rear counterpart, moves the chain across a limited number of chainrings, typically two or three. Proper adjustment is vital to avoid chain drops or hesitation between gear changes. Identifying the components is the first step. There are limit screws, often marked with an “H” (high) and “L” (low), that define the maximum and minimum travel of the derailleur cage. Cable tension, similar to the rear derailleur, also affects the quality of shifting. When addressing how to fix bicycle gears shifter, one must examine the front derailleur to ensure its proper alignment and function. Begin by inspecting the derailleur cage; it should be parallel to the chainrings, and positioned to shift the chain onto each chainring effectively without excessive rubbing. The limit screws prevent the chain from overshooting the largest or smallest chainrings, which can cause the chain to fall off. If the chain fails to shift up to the larger chainring, the ‘H’ limit screw should be adjusted, while the ‘L’ screw is to be used when shifting to the small chainring. Each adjustment of the screws should be tiny and tested with a full revolution of the pedals and change of gear.

To adjust the front derailleur correctly, start by ensuring the cable is properly connected and has sufficient tension. If shifting is slow or hesitant, adjust cable tension using the barrel adjuster, usually located near the shifter or on the cable housing. Turning the barrel adjuster counterclockwise will increase cable tension, while clockwise will reduce it. Make small, incremental adjustments, testing shifting after each change. Remember that, when learning how to fix bicycle gears shifter, these adjustments should be systematic. Too much tension can lead to difficult shifting to smaller chainrings, and insufficient tension can cause delays or failed shifts to larger chainrings. When fine tuning the high and low limit screws, start by making sure the chain is on the smallest chainring in the front and the smallest cog on the back (low-low setting). Adjust the “L” limit screw to prevent the chain from derailing inwards. Then shift the front to the largest chainring and rear to the smallest cog (high-high setting). Adjust the “H” limit screw to stop the chain from derailing outward. Correct alignment, proper cable tension, and precise limit screw adjustment are essential for seamless front shifting. Regular cleaning and lubrication are equally important, as dirt and grime can interfere with the derailleur’s movement and create unwanted friction which impedes shifting performance. Understanding these aspects of the front derailleur is a key component in learning how to fix bicycle gears shifter.

Cleaning and Lubrication: Essential Maintenance for Smooth Shifting

Regular cleaning and lubrication are crucial for maintaining smooth and efficient gear shifting on any bicycle. Dirt, grime, and old lubricant attract more dirt and impede the smooth operation of the derailleur, cassette, and chain. This can lead to sluggish shifting, skipping gears, and even chain breakage. To learn how to fix bicycle gears shifter problems effectively, proactive maintenance is key. A clean and well-lubricated drivetrain ensures optimal performance and extends the lifespan of your components. Begin by thoroughly cleaning the entire drivetrain using a degreaser designed for bicycle components. Apply the degreaser, and then use a brush or rag to remove built-up grime from the chain, cassette, derailleurs, and chainrings. Rinse the components thoroughly with water and allow them to completely dry before applying lubricant. Once dry, apply a bicycle-specific chain lubricant, following the manufacturer’s instructions. Ensure even coverage along the entire chain, and wipe away any excess lubricant. This cleaning and lubrication process should be performed regularly, approximately every few rides or after riding in muddy or wet conditions. Remember, regular maintenance is essential to understanding how to fix bicycle gears shifter issues before they become significant problems. Consistent cleaning and lubrication will prolong the life of your bike’s drivetrain and prevent more extensive repairs. By keeping your drivetrain clean and properly lubricated, you can ensure smoother and more precise gear changes, thereby enhancing your overall cycling experience.

Proper lubrication is just as important as cleaning for optimal drivetrain performance and learning how to fix bicycle gears shifter issues. Using the correct type of lubricant is crucial. Thick, heavy lubricants are generally suitable for dry or dusty conditions, while lighter lubricants perform better in wet or humid conditions. Applying too much lubricant can attract more dirt, leading to the buildup of grime. Therefore, it’s essential to use a moderate amount and wipe away any excess. Different lubricants have different application methods and drying times. Always follow the manufacturer’s instructions for best results. Pay close attention to areas where the chain articulates with the cassette and chainrings. These are the areas most susceptible to friction and wear. Applying lubricant directly to these points can help to reduce wear and improve shifting performance. In addition to lubricating the chain, consider applying a small amount of lubricant to the pivot points of the derailleur. These points can become stiff and difficult to move, so keeping them lubricated is essential for smooth shifting. Regular lubrication and cleaning will result in easier maintenance and will help you avoid many difficult situations when understanding how to fix bicycle gears shifter problems.

When cleaning and lubricating the bicycle drivetrain, prioritize safety. Wear gloves to protect your hands from degreasers and lubricants. Ensure proper ventilation when working with degreasers as they can have strong fumes. Remember to dispose of used degreasers responsibly in accordance with local regulations. Always refer to the manufacturer’s instructions for specific maintenance and lubrication recommendations for your bike’s components. By following these guidelines, cyclists can significantly improve the performance of their drivetrain and extend the lifespan of their bicycles. Consistent maintenance can make the difference between smooth, reliable shifting and frustrating mechanical problems. This also reduces the need to delve deeply into more complicated methods of how to fix bicycle gears shifter issues.

Index Shifting vs. Friction Shifting: Understanding the Differences for Smooth Gear Changes

Understanding the type of shifting system on your bicycle is crucial when learning how to fix bicycle gears shifter issues. Two primary systems exist: index and friction shifting. Index shifting, prevalent in modern bicycles, provides precise gear changes with distinct clicks. Each shift corresponds to a specific gear ratio, offering a predictable and consistent experience. The derailleur moves in discrete steps, controlled by indexed shifters that work in conjunction with precisely calibrated cable pull ratios. This mechanism simplifies gear selection and minimizes the chance of accidental gear changes, enhancing the overall riding experience. Components such as Shimano’s indexed systems or SRAM’s are common examples of this precise method. Learning how to fix bicycle gears shifter problems on an indexed system often involves adjusting cable tension for crisp shifting action, addressing issues such as cable stretch or derailleur alignment. Proper adjustment is key to smooth operation and optimal gear changes in this method, contributing to a more efficient and enjoyable ride.

In contrast, friction shifting offers continuous gear changes. The shifter controls the derailleur’s position without distinct clicks. This provides a more gradual transition between gears, useful in certain terrain or riding styles, but requires more rider skill and attention to avoid accidental shifts or chain slippage. It’s a system that’s typically found on older bikes or some specialized models. The cable tension directly influences the derailleur’s position. Adjusting friction shifters involves finding the sweet spot for each gear, which is usually more subtle and requires more practice. Troubleshooting friction shifting often necessitates meticulous adjustments to achieve smooth, consistent gear changes across the gear range. Unlike index systems where learning how to fix bicycle gears shifter problems centers on precision clicks, friction systems rely on finding a smooth movement between gears, eliminating or resolving the causes of gear slippage.

Knowing the differences between these systems is paramount when addressing gear shifting problems. The approach to troubleshooting and how to fix bicycle gears shifter issues will differ based on whether you are dealing with index or friction shifting. Understanding the nuances of each system enables more effective diagnosis and repair, ultimately leading to improved cycling performance. The choice of system is a matter of personal preference and riding style, but understanding how each one operates helps in successfully resolving any shifting problems. While learning how to fix bicycle gears shifter problems can seem daunting, understanding the underlying mechanics simplifies the process and allows for a more efficient and effective approach to maintenance. The appropriate adjustments for each type of shifting mechanism will directly improve the rider’s experience.

When to Seek Professional Help: Recognizing Limitations

While this guide provides comprehensive instructions on how to fix bicycle gears shifter and address common shifting problems, some situations require the expertise of a professional bicycle mechanic. Attempting repairs beyond one’s skill level can potentially worsen the issue, leading to more extensive and costly repairs. Understanding the limitations of DIY bicycle repair is crucial for maintaining a smoothly functioning bicycle. Recognizing the signs that indicate professional help is needed will save time, money, and potential frustration.

Several scenarios warrant seeking professional assistance. Severely bent derailleurs, for instance, often require specialized tools and techniques for proper straightening or replacement. Internal gear hubs, present in some bicycle designs, are intricate mechanisms that are best serviced by experienced mechanics. These internal systems demand precise adjustments and specialized knowledge to avoid causing further damage. Similarly, if after following the steps outlined in this guide on how to fix bicycle gears shifter you continue to experience persistent shifting problems despite thorough attempts at adjustment and cable replacement, a professional assessment is recommended. A mechanic can diagnose problems not readily apparent to the untrained eye and effectively address underlying issues that might be missed during self-repair attempts.

Ultimately, the decision of whether to tackle a repair independently or seek professional help hinges on one’s mechanical aptitude and the complexity of the problem. While this guide provides valuable information on how to fix bicycle gears shifter and offers solutions for numerous common issues, prioritizing the longevity and proper function of your bicycle often justifies professional intervention when facing challenging or persistent mechanical problems. Remember, prevention is key, and regular maintenance, including cleaning and lubrication, can significantly reduce the likelihood of requiring major repairs. A well-maintained bicycle will not only perform better but also minimize the need for complex repairs.