Understanding the Basics of Front Derailleur Mechanics

The front derailleur is a crucial component of your bicycle’s drivetrain. It is responsible for shifting the chain between the different chainrings at the crankset. This mechanism allows you to change gears and tackle varying terrain. Understanding its function is key to achieving optimal performance. The front derailleur setup shimano system, though appearing complex, follows straightforward mechanical principles. The derailleur cage, a metal guide, moves laterally. This action pushes the chain from one chainring to another. Proper adjustment is critical for smooth and efficient shifting. When misaligned or poorly adjusted, the front derailleur can cause dropped chains and noisy shifting.

A well-adjusted front derailleur provides precise gear changes. It contributes to the overall efficiency of your ride. The front derailleur setup shimano system relies on accurate positioning. The movement of the cage must be aligned perfectly with the chainrings. Correct cable tension is also crucial. These adjustments ensure a seamless transition between gears. When these settings are correct, each shift feels smooth and responsive. Neglecting the front derailleur can lead to frustrating riding experiences. Therefore, a proper front derailleur setup shimano configuration is vital. It ensures a pleasant and efficient cycling experience. Many issues such as chains rubbing or poor shifts are due to a poor front derailleur setup shimano.

How to Fine-Tune Your Shimano Front Derailleur

This section delves into the practical adjustments for a Shimano front derailleur setup. While specific steps might vary slightly depending on the exact model, the underlying principles remain consistent across most Shimano front derailleur setups. This guide focuses on those core principles, enabling you to effectively adjust your front derailleur. Key components involved in this process include the limit screws—high and low—cable tension, and the derailleur’s height and angle relative to the chainrings. Mastering these adjustments is key to achieving optimal front derailleur setup shimano performance. Understanding how these elements interact is crucial for smooth, precise shifting. The following sections will break down each adjustment step-by-step, providing clear instructions and troubleshooting tips for a successful front derailleur setup shimano.

Before beginning any adjustments, ensure your bike is securely supported. A work stand is highly recommended. Begin by visually inspecting the front derailleur for any obvious damage or misalignment. Check the cable for kinks or fraying. Lubricate the cable housing to ensure smooth cable movement. This simple step often resolves many shifting issues. Then, familiarize yourself with the location of the high and low limit screws, and the barrel adjuster (if present). These are the primary tools for making precise adjustments to your front derailleur setup shimano. Small, incremental adjustments are key to avoiding over-correction and achieving the optimal front derailleur setup shimano. Remember to test your shifts frequently, both while stationary and under load to confirm each adjustment is correct. The goal is precise, smooth shifting across all gears. A properly adjusted front derailleur setup shimano ensures reliable performance and extends the life of your drivetrain components.

Accurate front derailleur setup shimano is essential for seamless gear changes. Improperly adjusted limit screws can lead to chain drops, while incorrect cable tension results in sluggish or imprecise shifting. The derailleur’s height and angle also play a crucial role, impacting chain clearance and preventing chain rub. By carefully following the instructions and paying attention to the details, you can achieve a front derailleur setup shimano that delivers consistent and reliable performance. This will improve your riding experience significantly. Remember that a well-maintained front derailleur is a key component of a high-performing bicycle. Regular inspection and minor adjustments will ensure many miles of smooth, reliable shifting.

Setting the Low Limit Screw for Optimal Shifting

The low limit screw on your Shimano front derailleur prevents the chain from falling off the inner chainring. Correct front derailleur setup shimano is crucial for smooth shifting. To adjust this screw, first locate it on the derailleur. It’s usually a small screw near the bottom of the derailleur cage. Turn the screw clockwise to move the derailleur closer to the inner chainring. Make tiny adjustments, testing after each one. Shift to your smallest gear. The chain should sit comfortably on the inner chainring without rubbing against the derailleur cage. If the chain rubs, the screw is too tight. Unscrew it slightly until the rubbing stops. If the chain drops off the inner chainring when shifting, the screw is too loose. Turn it clockwise until it engages correctly. This process ensures your front derailleur setup shimano functions perfectly for small chainring shifts.

Troubleshooting issues with the low limit screw often involves small incremental adjustments. Chain rub against the derailleur cage indicates the screw is turned too far. This can damage your chain and derailleur over time. If the chain consistently slips off the inner chainring under load, insufficient tension is often the culprit. Recheck your cable tension and ensure your front derailleur setup shimano is correctly aligned with the chainrings. Remember, small adjustments are key to achieving the optimal setting. Over-tightening can lead to derailleur damage or impede smooth shifting. Achieving the correct front derailleur setup shimano will make a noticeable difference in your riding experience. Proper adjustment improves shifting reliability and prevents costly repairs.

Improper front derailleur setup shimano can lead to significant problems. A poorly adjusted low limit screw can result in dropped chains, especially when pedaling hard. This is frustrating and potentially dangerous, leading to a loss of control. To fine-tune this crucial aspect of your front derailleur setup shimano, remember that small, incremental adjustments are your best friends. Always test your shifts after each adjustment, paying attention to how the chain behaves under load. Consider using a visual guide or video to help you identify the low limit screw and gain a better understanding of the adjustment process. This attention to detail will ensure a smooth, consistent ride every time.

Adjusting the High Limit Screw for Smooth Gear Changes

The high limit screw on your Shimano front derailleur prevents the chain from falling off the large chainring. Correct front derailleur setup shimano is crucial for smooth shifting. This screw controls the derailleur’s outward movement. Adjusting it incorrectly can lead to chain skipping or dropping onto the frame. To adjust, locate the high limit screw, usually on the top or side of the derailleur. It’s often clearly marked with an “H” or “High.” Turn the screw clockwise to limit the derailleur’s outward travel. Turn it counter-clockwise to increase travel. Make small adjustments, testing the shift each time. Shift to the large chainring. If the chain doesn’t fully engage, turn the screw slightly counter-clockwise. If the chain rubs against the derailleur cage or drops off, turn the screw clockwise. Repeat until the chain shifts smoothly to the large chainring without issue. This precision is key for optimal front derailleur setup shimano performance.

A properly adjusted high limit screw ensures clean shifts to the large chainring. If the screw is too loose, the chain may not fully engage on the large ring, causing it to skip or drop. Conversely, if it’s too tight, the chain might rub against the derailleur cage. This friction creates noise and could potentially damage your drivetrain components. A properly adjusted high limit screw contributes significantly to an efficient front derailleur setup shimano. Remember to test your shifts under load, not just while pedaling slowly. This is where you’ll truly feel the impact of proper adjustment. Front derailleur setup shimano becomes much more intuitive once you grasp the relationship between the limit screws and the overall smoothness of shifting.

Troubleshooting a poorly adjusted high limit screw often involves systematically adjusting the screw and testing. Start with small incremental adjustments and ensure the cable is lubricated and moves freely within its housing. Remember that achieving perfect front derailleur setup shimano is an iterative process. It might take several small adjustments to find the sweet spot. Consistent testing under varied pedaling forces will identify any issues remaining after adjustments. Pay close attention to any rubbing or chain skipping when shifting to the large chainring. These are clear indicators that further adjustments to the high limit screw or cable tension are needed. The goal is to achieve a smooth, positive shift every time without any unwanted noise or friction. This marks a successful front derailleur setup shimano.

Cable Tension: The Key to Precise Shifting in Your Shimano Front Derailleur Setup

Proper cable tension is crucial for optimal front derailleur setup shimano performance. Too much tension can lead to sluggish shifting or the inability to shift into the smallest chainring. Conversely, insufficient tension results in imprecise shifts, causing the chain to drop or struggle to reach the largest chainring. Achieving the ideal tension ensures smooth, accurate gear changes across all chainrings. This is a key aspect of any successful front derailleur setup shimano guide.

Adjusting cable tension typically involves using barrel adjusters. These are small, threaded barrels located either on the shifter itself or inline on the derailleur cable. Turning the barrel clockwise increases cable tension, while counter-clockwise rotation decreases it. Make incremental adjustments, testing the shifts after each small turn. Aim for smooth, decisive shifts under both no-load and pedaling conditions. Remember to test shifts across all gear combinations to ensure consistent performance. A properly adjusted front derailleur setup shimano will allow for effortless gear changes.

Beyond barrel adjusters, the smooth operation of the cable within its housing significantly impacts shifting. Regular lubrication of the cable housing ensures friction-free cable movement. This is especially important for maintaining optimal front derailleur setup shimano. A stiff cable within its housing will hinder precise tension adjustments, compromising shifting performance. Therefore, keeping your cables clean and lubricated contributes significantly to the longevity and effectiveness of your front derailleur. Prioritize cable maintenance for a reliable front derailleur setup shimano.

Optimizing Derailleur Height and Angle for Consistent Shifting

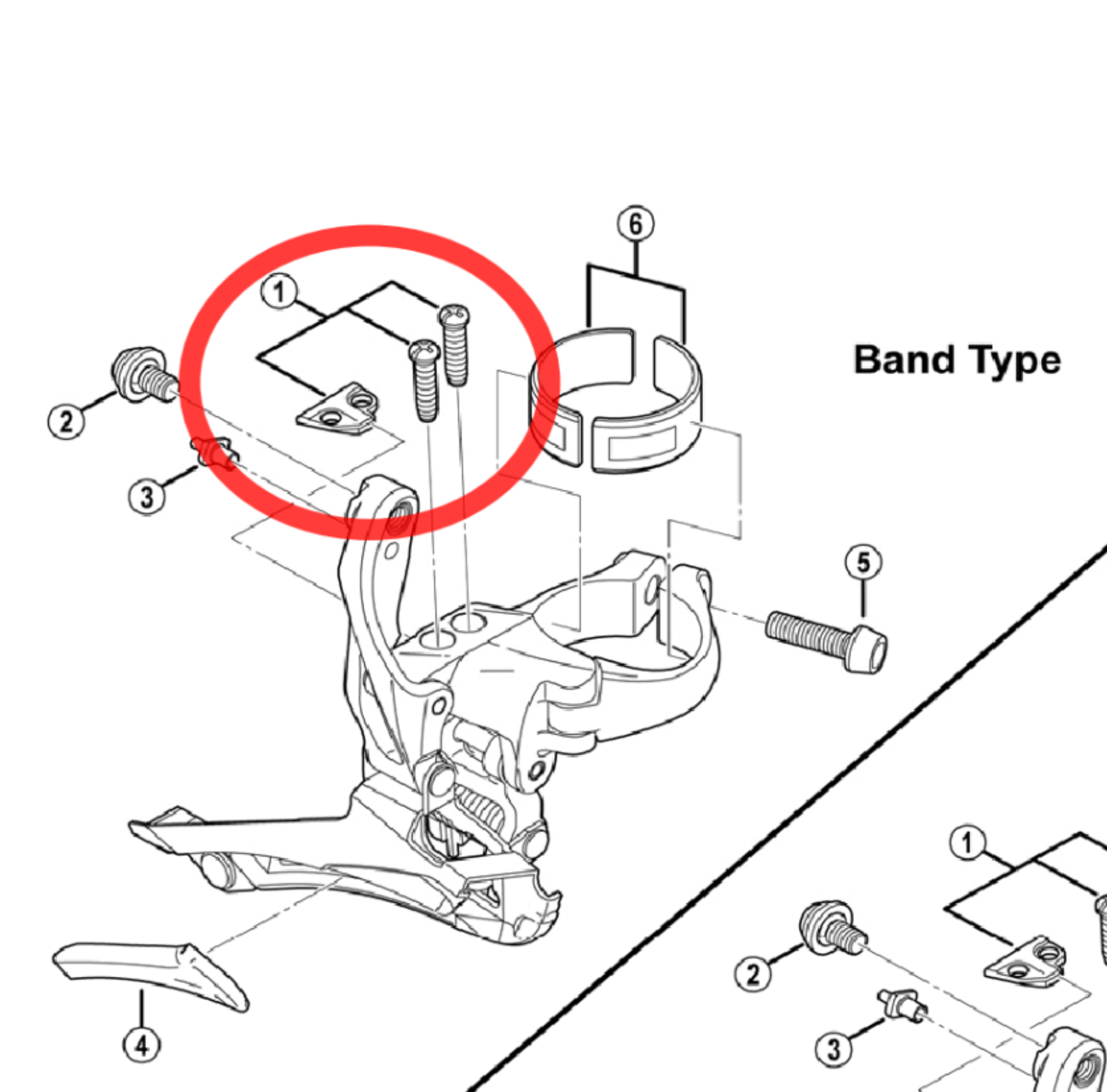

Proper front derailleur height and angle are crucial for smooth, reliable shifting in a front derailleur setup shimano. The derailleur cage needs to be positioned correctly relative to the chainrings to prevent chain rub and ensure clean gear changes, especially during cross-chaining (using the largest or smallest cog on the cassette with the largest or smallest chainring). Incorrect height can lead to inconsistent shifting or chain drops. The angle influences how effectively the derailleur guides the chain onto the correct chainring. A simple ruler can help assess these parameters. Measure the distance between the derailleur cage and the chainrings, aiming for the manufacturer’s specifications. Adjusting the derailleur’s position on the clamp usually corrects height issues. You might need an Allen wrench or other tools, depending on your bike’s design. Slight adjustments can make a big difference.

When checking the front derailleur setup shimano angle, ensure the derailleur cage is parallel to the chainrings. A slight bend inward or outward will affect performance. Improper angles often result from incorrect installation or cable tension. Observing the chain’s path as you shift is a great way to identify angular problems. If the chain rubs against the derailleur cage, the angle needs adjustment. This often requires loosening the clamp bolts, repositioning the derailleur, and then tightening the bolts. Pay close attention to this positioning; even small discrepancies can affect the smooth function of your front derailleur setup shimano. Remember to re-test your shifting after making any adjustments.

Optimizing both height and angle is iterative. Adjust one parameter, test the shifting, and then fine-tune the other. Repeat this process until the shifts are consistently smooth and precise across all gears. A well-adjusted front derailleur setup shimano contributes significantly to a positive riding experience. It also enhances the longevity of your drivetrain components. Accurate chain alignment minimizes wear and tear on the chain, chainrings, and cassette. Addressing these factors during a front derailleur setup shimano process is fundamental for optimal performance. Taking the time to achieve proper alignment ensures a smoother, more efficient ride and contributes significantly to your overall cycling enjoyment.

Troubleshooting Common Issues with Shimano Front Derailleurs

When the Shimano front derailleur setup is not optimal, several issues can arise, impacting shifting performance. A common problem is slow or missed shifts, where the chain hesitates to move between chainrings. This often stems from incorrect cable tension. If the cable is too loose, the derailleur may not have enough force to push the chain onto the larger ring. Conversely, excessive tension can hinder smooth movement to the smaller ring. Adjusting the barrel adjuster on the shifter or cable can often resolve this. Another frequent issue involves the chain dropping off either the inner or outer chainring. This usually indicates an improperly set limit screw. The low limit screw prevents the chain from falling off the small chainring. The high limit screw serves the same purpose for the large chainring. Refer to the previous sections on limit screw adjustments to correct these problems.

Persistent chain rub against the derailleur cage is another common frustration with front derailleur setup shimano. This is often due to incorrect derailleur height or angle. If the derailleur cage is too low or improperly angled, it will make contact with the chain during operation, particularly when cross-chaining. Adjust the derailleur height and angle to ensure adequate clearance. Another cause of chain rub can be a bent derailleur cage; inspect it carefully for damage. Difficulty shifting under load might point to other issues like cable friction. Ensure cables move freely within their housings. Lubrication might be necessary. Always test adjustments incrementally, checking shifting performance after each change. Regularly performing maintenance is a key step for avoiding these issues.

Sometimes, even with careful adjustments, shifting issues can persist. It’s important to recheck all previous steps. Confirm that the limit screws are correctly positioned. Verify that cable tension is optimal. Ensure the derailleur is at the correct height and angle. If the problem remains, a worn cable or housing may be the cause of the poor front derailleur setup shimano. Replace these components. Sometimes, the derailleur itself can be damaged, requiring replacement. By systematically addressing each possible cause, most issues can be resolved and the front derailleur setup shimano can achieve optimal performance, providing you with smooth and reliable gear changes.

Maintaining Your Shimano Front Derailleur for Long-Term Performance

Proper maintenance ensures a long life for your front derailleur setup shimano and consistently smooth shifting. Regular cleaning is key. Dirt and grime can hinder the derailleur’s movement, making shifting sluggish. Use a brush and a degreaser to clean the derailleur body, the cage, and the pivot points. After cleaning, lubricate all moving parts. A light chain oil or a dry lubricant can be used. Apply a small amount to each pivot point. This will keep the components moving smoothly. Inspect your front derailleur setup shimano regularly. Look for signs of wear and tear. Check the derailleur cage for bending or damage. Ensure the cable is not frayed or kinked. Replace worn parts immediately to prevent further issues. Always check the cable tension periodically. The cable can stretch over time, affecting shifting. Adjust the tension if needed by using the barrel adjusters. These are usually found on the shifter or in-line on the cable.

Pay particular attention to the cable and its housing. Smooth cable movement is essential for accurate shifting. If the cable housing is damaged or the cable is stiff, shifting will be affected. Replacing the cable and housing is a straightforward job that greatly improves the performance of your front derailleur setup shimano. A well-maintained cable also ensures the correct front derailleur setup shimano function. Inspect your cable at regular intervals. The goal is smooth shifting and reliable performance. Remember, a little maintenance goes a long way. Investing a few minutes in routine care will ensure the front derailleur performs as intended. Consistent attention to these details guarantees your front derailleur setup shimano provides smooth gear changes for years to come. It will provide a consistent user experience and greatly reduce the time required to fix it. This will save time, money and frustration in the long run.

By paying attention to the simple steps above, you will ensure the lifespan of your front derailleur. Proper cleaning, lubricating, and inspection are essential parts of bike maintenance. These steps will greatly improve the performance of your front derailleur setup shimano. Regular maintenance leads to consistent and reliable shifting performance for many years. Always double-check your work. Test shifting thoroughly after any maintenance tasks. With correct front derailleur setup shimano and care, your front derailleur will function smoothly. You will enjoy the smooth and reliable shifts on your bike for years to come. These simple steps are essential for long-term performance. This will help you get the best performance from the bicycle’s drivetrain, ultimately saving you money and time in the long run. Always use good quality tools for your bike maintenance tasks.