The Benefits of Going Tubeless

Tubeless tires have gained popularity among cyclists due to their ability to provide improved traction, reduced weight, and increased puncture resistance. By eliminating the inner tube, tubeless tires allow for a more direct connection between the tire and the rim, resulting in better handling and responsiveness. Additionally, the reduced weight of tubeless tires can lead to improved acceleration and climbing performance. Perhaps most importantly, tubeless tires are more resistant to punctures, as the sealant inside the tire can quickly seal small holes and cracks. When it comes to adding sealant to tubeless tires, this benefit is further enhanced, as the sealant can effectively seal larger punctures and reduce the risk of air leaks. By understanding the advantages of tubeless tires and the importance of adding sealant, cyclists can unlock the full potential of their tires and enjoy a smoother, more reliable ride.

Why Sealant is a Game-Changer for Tubeless Tires

Sealant is a crucial component of tubeless tires, playing a vital role in maintaining the integrity and performance of the tire. By adding sealant to tubeless tires, cyclists can enjoy the benefits of self-healing punctures and reduced air leaks. This means that even if a tire is punctured, the sealant can quickly seal the hole, allowing the rider to continue riding without interruption. Furthermore, sealant helps to reduce the risk of air leaks, which can lead to a loss of tire pressure and decreased performance. Without sealant, tubeless tires are more susceptible to frequent flats and decreased tire lifespan, making regular maintenance and repairs a necessity. By understanding the importance of sealant in tubeless tires, cyclists can unlock the full potential of their tires and enjoy a smoother, more reliable ride. In fact, adding sealant to tubeless tires is a key step in mastering tubeless tire maintenance, as it provides an additional layer of protection and performance.

How to Choose the Right Sealant for Your Tubeless Tires

Selecting the right sealant for tubeless tires is crucial to ensure optimal performance and puncture resistance. With numerous sealant brands and types available, it can be overwhelming to choose the best one for your needs. When choosing a sealant, consider factors such as tire size, riding style, and environmental conditions. For example, riders who frequent rough terrain may require a more robust sealant, while those who ride on smooth roads may opt for a lighter, more efficient option. Popular sealant brands, such as Stan’s NoTubes and Orange Seal, offer a range of products tailored to specific needs. Stan’s NoTubes, for instance, offers a variety of sealants designed for different tire sizes and riding styles, while Orange Seal provides eco-friendly options for environmentally conscious riders. By considering these factors and exploring the various sealant options available, cyclists can make an informed decision and ensure their tubeless tires are properly protected. Remember, adding sealant to tubeless tires is a critical step in maintaining their performance and longevity, so choosing the right sealant is essential.

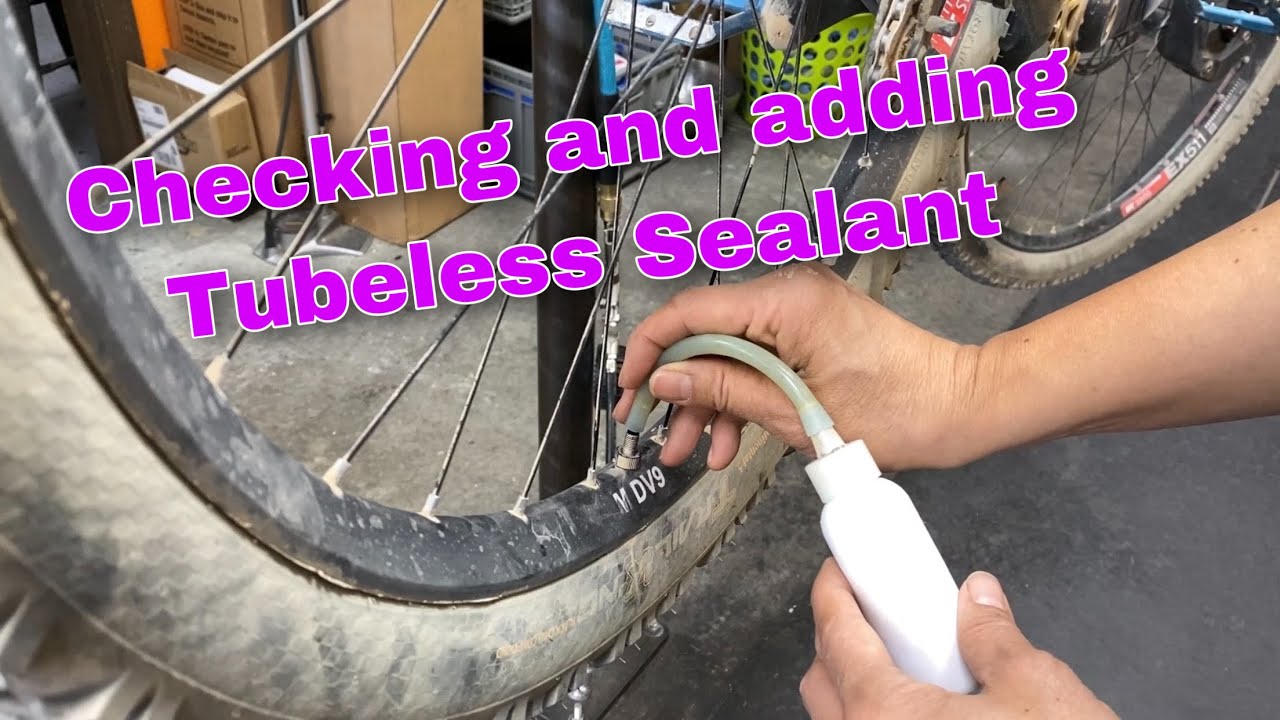

A Step-by-Step Guide to Adding Sealant to Your Tubeless Tires

Adding sealant to tubeless tires is a crucial step in maintaining their performance and longevity. To ensure a successful installation, follow this step-by-step guide:

Preparation:

Before adding sealant, make sure your tubeless tires are clean and free of debris. Remove any existing sealant or residue using a tire cleaning solution and a brush. Inspect the tire for any punctures or damage and repair them before proceeding.

Application:

Shake the sealant bottle well and attach the nozzle to the valve stem. Inject the recommended amount of sealant into the tire, typically 1-2 ounces for most tires. Rotate the tire to distribute the sealant evenly, ensuring it coats the entire inner surface.

Inspection:

After adding sealant, inspect the tire for any signs of leakage or uneven distribution. Check the valve stem and tire sidewalls for any sealant residue or drips. If necessary, use a clean cloth to wipe away excess sealant.

Tips and Tricks:

To ensure proper sealant distribution, rotate the tire multiple times and inspect it from different angles. Avoid overfilling the tire with sealant, as this can lead to excessive leakage and mess. When adding sealant to tubeless tires, it’s essential to follow the manufacturer’s instructions and recommendations for the specific tire and sealant being used.

By following these steps and tips, cyclists can successfully add sealant to their tubeless tires, ensuring improved puncture resistance, reduced maintenance, and enhanced overall performance. Remember, adding sealant to tubeless tires is a critical step in mastering tubeless tire maintenance, and with practice, it becomes a straightforward process.

Troubleshooting Common Issues with Sealant in Tubeless Tires

While adding sealant to tubeless tires can provide numerous benefits, it’s not immune to potential issues. Being aware of these common problems and knowing how to address them can help cyclists optimize their tubeless tire performance and avoid frustrating setbacks.

Clogged Valves:

One of the most common issues with sealant in tubeless tires is clogged valves. This occurs when sealant residue accumulates on the valve stem, preventing air from flowing in or out of the tire. To prevent clogged valves, regularly clean the valve stem and surrounding area with a soft brush and mild soap. If the valve is already clogged, try soaking it in warm water and gentle soap to loosen the sealant residue.

Excessive Sealant Leakage:

Excessive sealant leakage can be a frustrating issue, especially when it occurs during a ride. To minimize leakage, ensure the tire is properly seated on the rim and the valve stem is securely tightened. If leakage persists, try applying a small amount of sealant to the affected area to help seal the puncture.

Tire Pressure Fluctuations:

Tire pressure fluctuations can occur when sealant affects the tire’s ability to hold air. To address this issue, regularly check tire pressure and adjust as needed. Additionally, consider using a sealant specifically designed to minimize pressure fluctuations.

By being aware of these common issues and taking preventative measures, cyclists can minimize the risk of problems and ensure their tubeless tires perform optimally. Remember, adding sealant to tubeless tires is a critical step in mastering tubeless tire maintenance, and with the right knowledge and techniques, cyclists can enjoy a hassle-free riding experience.

Sealant Maintenance and Inspection: Best Practices

Regular sealant maintenance and inspection are crucial to ensuring optimal tubeless tire performance and extending the lifespan of the sealant. By following these best practices, cyclists can avoid common issues and enjoy a hassle-free riding experience.

Checking Sealant Levels:

Regularly inspect the sealant level in your tubeless tires to ensure it’s within the recommended range. Low sealant levels can compromise the tire’s ability to self-heal punctures, while excessive sealant can lead to leakage and mess. Use a sealant level indicator or consult the manufacturer’s guidelines to determine the optimal level for your specific tire.

Inspecting Tire Condition:

Regularly inspect the tire’s condition, looking for signs of wear, damage, or excessive sealant buildup. Check the tire’s sidewalls, tread, and bead area for any signs of damage or wear. Addressing these issues promptly can help prevent more serious problems from developing.

Routine Cleaning:

Regularly clean the tire and rim to prevent dirt and debris from accumulating and affecting sealant performance. Use a mild soap and soft brush to clean the tire, and avoid using harsh chemicals or abrasive materials that can damage the tire or rim.

Tips for Extending Sealant Lifespan:

To extend the lifespan of your sealant, avoid mixing different sealant brands or types, as this can compromise their effectiveness. Additionally, store your tubeless tires in a cool, dry place, away from direct sunlight, to prevent sealant degradation. By following these best practices, cyclists can optimize their tubeless tire performance, reduce maintenance, and enjoy a superior riding experience.

Comparing Sealant Brands: What Sets Them Apart

With numerous sealant brands available on the market, choosing the right one for your tubeless tires can be overwhelming. Understanding the unique features, advantages, and disadvantages of popular sealant brands can help cyclists make an informed decision. In this section, we’ll compare and contrast some of the most popular sealant brands, highlighting their differences and similarities.

Stan’s NoTubes:

Stan’s NoTubes is a well-established brand in the tubeless tire market, offering a range of sealants designed for specific tire sizes and riding styles. Their sealants are known for their excellent puncture-sealing capabilities and are a popular choice among professional cyclists. One of the unique features of Stan’s NoTubes sealants is their ability to be used in both tubeless and tubular tires.

Orange Seal:

Orange Seal is another popular sealant brand, offering a range of products designed for different tire sizes and riding conditions. Their sealants are known for their excellent durability and ability to seal larger punctures. One of the unique features of Orange Seal is their proprietary formula, which is designed to be more environmentally friendly than other sealant brands.

Other Sealant Brands:

In addition to Stan’s NoTubes and Orange Seal, there are several other sealant brands available on the market, including Slime, Finish Line, and Hutchinson. Each of these brands offers unique features and benefits, such as Slime’s ability to seal larger punctures and Finish Line’s eco-friendly formula.

Factors to Consider:

When choosing a sealant brand, there are several factors to consider, including price, performance, and environmental impact. Cyclists should also consider the specific needs of their tubeless tires, such as tire size, riding style, and environmental conditions. By considering these factors and understanding the unique features of each sealant brand, cyclists can make an informed decision and choose the best sealant for their tubeless tires.

Ultimately, the key to successful tubeless tire maintenance is adding sealant to tubeless tires. By choosing the right sealant brand and following proper maintenance and inspection procedures, cyclists can enjoy improved puncture resistance, reduced maintenance, and enhanced overall performance.

Conclusion: Sealing Your Way to Tubeless Tire Success

By now, it’s clear that adding sealant to tubeless tires is a crucial step in unlocking their full potential. With the right sealant, tubeless tires can provide improved traction, reduced weight, and increased puncture resistance. By following the guidelines outlined in this article, cyclists can ensure a hassle-free riding experience, free from the frustrations of frequent flats and decreased tire lifespan.

Remember, adding sealant to tubeless tires is not a one-time task, but rather an ongoing process that requires regular maintenance and inspection. By staying on top of sealant levels, inspecting tire condition, and performing routine cleaning, cyclists can extend the lifespan of their sealant and optimize tire performance.

Whether you’re a seasoned pro or a beginner, mastering tubeless tire maintenance is within your reach. By choosing the right sealant, following proper installation and maintenance procedures, and staying informed about the latest developments in tubeless tire technology, cyclists can take their riding to the next level.

So why wait? Take the first step in mastering tubeless tire maintenance today. Add sealant to your tubeless tires, and discover the benefits of improved puncture resistance, reduced maintenance, and enhanced overall performance. With the right knowledge and tools, you’ll be sealing your way to tubeless tire success in no time.