Artificial Intelligence: Transforming Modern Manufacturing

Artificial Intelligence (AI) has become a game-changer in various industries, revolutionizing the way businesses operate and deliver value to their customers. One such sector that is experiencing significant transformation due to AI is eBike manufacturing. AI applications in eBike manufacturing offer the potential to enhance efficiency, productivity, and product quality, providing a competitive edge for manufacturers in the rapidly growing eBike market.

The Rise of eBikes: Market Trends and Consumer Demands

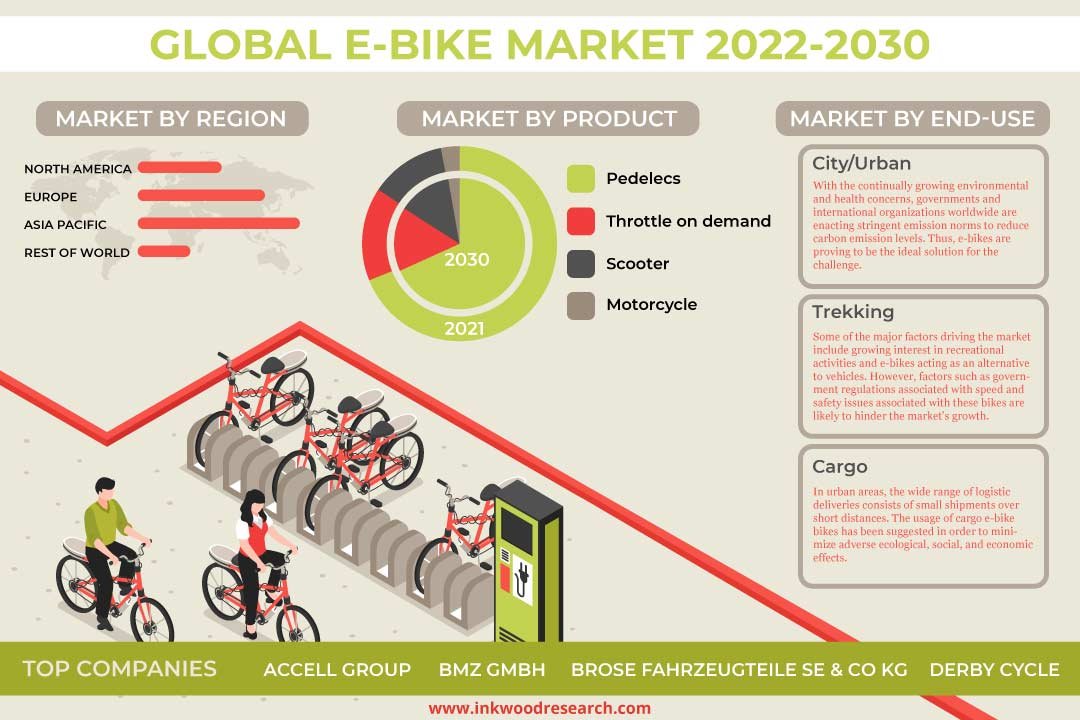

The eBike market has witnessed remarkable growth in recent years, driven by increasing environmental awareness, rising fuel prices, and a shift towards healthier lifestyles. According to a report by Allied Market Research, the global eBike market was valued at $15,730 million in 2016 and is projected to reach at $23,831 million by 2025, growing at a CAGR of 5.4% from 2

How AI Enhances eBike Manufacturing: Key Applications

Artificial Intelligence (AI) has become a game-changer in the eBike manufacturing sector, offering innovative solutions to enhance efficiency, productivity, and product quality. By leveraging AI applications in eBike manufacturing, companies can gain a competitive edge and meet the evolving needs of consumers.

One key AI application is predictive maintenance, which involves using AI algorithms to analyze data from sensors embedded in eBikes. By monitoring various parameters, such as battery health, motor temperature, and pedal assist levels, these algorithms can predict potential failures before they occur. As a result, manufacturers can schedule maintenance proactively, reducing downtime and increasing the lifespan of eBikes. This not only improves customer satisfaction but also helps manufacturers save on repair costs and minimize waste.

Another important AI application is smart inventory management. AI-powered systems can analyze historical sales data, production schedules, and supplier lead times to optimize inventory levels. By predicting demand fluctuations and ensuring a seamless production flow, manufacturers can minimize waste, reduce costs, and improve their overall supply chain management. This, in turn, leads to better product availability and enhanced customer satisfaction.

Personalized eBike design is another area where AI shines. By analyzing customer data, such as demographics, riding habits, and preferences, AI algorithms can suggest personalized design options tailored to individual customers. This not only improves customer satisfaction but also helps manufacturers differentiate their products in a highly competitive market. By offering custom eBikes, manufacturers can create a loyal customer base and increase their market share.

In summary, AI applications in eBike manufacturing offer numerous benefits, from predictive maintenance and smart inventory management to personalized eBike design. By embracing these innovative technologies, manufacturers can improve their manufacturing processes, create better end products, and meet the evolving needs of consumers. However, implementing AI in eBike manufacturing also comes with challenges, such as data privacy, cybersecurity, and integration with existing systems. Manufacturers must carefully consider these factors and develop a strategic approach to AI adoption to fully realize its potential.

Predictive Maintenance: Keeping eBikes Running Smoothly

Predictive maintenance is a powerful AI application in eBike manufacturing that can significantly improve the lifespan and performance of eBikes. By analyzing data from sensors embedded in eBikes, AI algorithms can predict potential failures before they occur, enabling manufacturers to schedule maintenance proactively and reduce downtime.

Sensors in eBikes collect data on various parameters, such as battery health, motor temperature, pedal assist levels, and other critical components. AI algorithms analyze this data in real-time, identifying patterns and trends that may indicate potential issues. By continuously monitoring these parameters, AI algorithms can predict failures with a high degree of accuracy, allowing manufacturers to take action before a minor issue becomes a major problem.

Predictive maintenance offers numerous benefits for eBike manufacturers. By reducing downtime and increasing the lifespan of eBikes, manufacturers can improve customer satisfaction and loyalty. Additionally, predictive maintenance can help manufacturers save on repair costs and minimize waste, leading to a more efficient and sustainable manufacturing process. By implementing predictive maintenance, eBike manufacturers can stay ahead of the competition and meet the evolving needs of consumers.

However, predictive maintenance also comes with challenges. Manufacturers must ensure that sensors are accurately collecting data and that AI algorithms are correctly interpreting this data. Additionally, manufacturers must consider data privacy and cybersecurity concerns, ensuring that sensitive data is protected and only used for predictive maintenance purposes. To overcome these challenges, manufacturers must develop a strategic approach to predictive maintenance, integrating it into their existing manufacturing processes and ensuring that it aligns with their overall business objectives.

In summary, predictive maintenance is a powerful AI application in eBike manufacturing that can significantly improve the lifespan and performance of eBikes. By analyzing data from sensors embedded in eBikes, AI algorithms can predict potential failures before they occur, enabling manufacturers to schedule maintenance proactively and reduce downtime. While predictive maintenance comes with challenges, manufacturers can overcome these challenges by developing a strategic approach and integrating predictive maintenance into their existing manufacturing processes.

Smart Inventory Management: Ensuring Seamless Production Flow

Smart inventory management is a crucial AI application in eBike manufacturing that can significantly improve the efficiency and productivity of the manufacturing process. AI-powered systems can analyze historical sales data, production schedules, and supplier lead times to ensure optimal inventory levels and minimize waste.

Traditional inventory management methods often rely on manual processes and can be time-consuming and prone to errors. However, AI-powered systems can automate these processes, providing real-time insights into inventory levels and demand patterns. By analyzing historical sales data, AI algorithms can predict future demand, enabling manufacturers to adjust inventory levels accordingly and minimize waste. Additionally, AI algorithms can analyze production schedules and supplier lead times to ensure that the necessary components are available when needed, reducing downtime and improving production flow.

Smart inventory management offers numerous benefits for eBike manufacturers. By minimizing waste and reducing downtime, manufacturers can improve efficiency and productivity, leading to cost savings and increased profitability. Additionally, smart inventory management can help manufacturers meet consumer demands for timely delivery and high-quality products. By implementing AI-powered inventory management systems, manufacturers can stay ahead of the competition and meet the evolving needs of consumers.

However, smart inventory management also comes with challenges. Manufacturers must ensure that AI algorithms are accurately analyzing data and that inventory levels are aligned with production schedules and demand patterns. Additionally, manufacturers must consider data privacy and cybersecurity concerns, ensuring that sensitive data is protected and only used for inventory management purposes. To overcome these challenges, manufacturers must develop a strategic approach to inventory management, integrating it into their existing manufacturing processes and ensuring that it aligns with their overall business objectives.

In summary, smart inventory management is a powerful AI application in eBike manufacturing that can significantly improve the efficiency and productivity of the manufacturing process. By analyzing historical sales data, production schedules, and supplier lead times, AI-powered systems can ensure optimal inventory levels and minimize waste. While smart inventory management comes with challenges, manufacturers can overcome these challenges by developing a strategic approach and integrating smart inventory management into their existing manufacturing processes.

Personalized eBike Design: Meeting Unique Customer Needs

The eBike market is rapidly evolving, with consumers demanding more personalized and customized products. AI applications in eBike manufacturing can help manufacturers meet these unique customer needs by analyzing customer data and suggesting personalized design options. This approach not only improves customer satisfaction but also sets manufacturers apart from their competitors.

AI algorithms can analyze customer data, including demographics, riding habits, and preferences, to suggest personalized eBike designs. For example, an AI system may suggest a lightweight eBike with a sleek design for a younger, urban customer who primarily uses their eBike for commuting. On the other hand, an AI system may suggest a more rugged eBike with a longer-range battery for an older customer who enjoys long-distance cycling.

Personalized eBike design also offers numerous benefits for manufacturers. By analyzing customer data, manufacturers can gain valuable insights into consumer preferences and tailor their products accordingly. This approach can lead to increased sales, improved customer loyalty, and a stronger brand reputation. Additionally, personalized eBike design can help manufacturers reduce costs associated with producing and storing unsold inventory.

However, personalized eBike design also comes with challenges. Manufacturers must ensure that AI algorithms are accurately analyzing customer data and suggesting personalized design options that meet customer needs. Additionally, manufacturers must consider data privacy and cybersecurity concerns, ensuring that customer data is protected and only used for personalized design purposes. To overcome these challenges, manufacturers must develop a strategic approach to personalized eBike design, integrating it into their existing manufacturing processes and ensuring that it aligns with their overall business objectives.

In summary, personalized eBike design is a powerful AI application in eBike manufacturing that can help manufacturers meet unique customer needs and improve customer satisfaction. By analyzing customer data, AI algorithms can suggest personalized design options that meet customer preferences. While personalized eBike design comes with challenges, manufacturers can overcome these challenges by developing a strategic approach and integrating personalized eBike design into their existing manufacturing processes.

Challenges and Considerations: Implementing AI in eBike Manufacturing

While AI applications in eBike manufacturing offer numerous benefits, manufacturers must also consider the challenges and considerations associated with implementing AI technologies. By addressing these challenges head-on, manufacturers can successfully integrate AI into their existing manufacturing processes and reap the rewards of improved efficiency, productivity, and product quality.

One of the primary challenges of implementing AI in eBike manufacturing is data privacy. Manufacturers must ensure that customer data is protected and only used for the intended purpose of improving manufacturing processes and end products. To address this challenge, manufacturers should develop clear data privacy policies and procedures, outlining how customer data is collected, stored, and used. Additionally, manufacturers should consider implementing data encryption and access controls to prevent unauthorized access to sensitive data.

Cybersecurity is another challenge associated with AI applications in eBike manufacturing. Manufacturers must ensure that their AI systems are secure from cyber threats, such as hacking and malware. To address this challenge, manufacturers should implement robust cybersecurity measures, such as firewalls, intrusion detection systems, and regular security updates. Additionally, manufacturers should consider hiring cybersecurity experts to help identify and mitigate potential security risks.

Integration with existing systems is another challenge associated with implementing AI in eBike manufacturing. Manufacturers must ensure that their AI systems are compatible with their existing manufacturing processes and systems. To address this challenge, manufacturers should consider working with AI vendors who have experience integrating AI systems into existing manufacturing processes. Additionally, manufacturers should consider conducting thorough testing and pilot programs before fully implementing AI systems.

To successfully implement AI in eBike manufacturing, manufacturers must also consider the cost of AI technologies. While AI offers numerous benefits, it can also be expensive to implement and maintain. To address this challenge, manufacturers should conduct a thorough cost-benefit analysis, evaluating the potential benefits of AI technologies against the cost of implementation and maintenance. Additionally, manufacturers should consider exploring funding opportunities, such as government grants and private investments, to help offset the cost of AI technologies.

In summary, implementing AI in eBike manufacturing comes with challenges and considerations, including data privacy, cybersecurity, integration with existing systems, and cost. However, by addressing these challenges head-on and working with experienced AI vendors, manufacturers can successfully integrate AI into their existing manufacturing processes and reap the rewards of improved efficiency, productivity, and product quality. By taking a strategic and thoughtful approach to AI implementation, manufacturers can position themselves for long-term success in the eBike manufacturing industry.

The Future of AI in eBike Manufacturing: Opportunities and Innovations

As AI technologies continue to advance, the potential for AI applications in eBike manufacturing is vast and exciting. Emerging trends and innovations in AI are poised to revolutionize the eBike manufacturing industry, offering numerous benefits for manufacturers and consumers alike. By embracing these opportunities and innovations, manufacturers can position themselves for long-term success and growth in the eBike market.

One emerging trend in AI is the use of machine learning algorithms to optimize eBike design and performance. By analyzing data from sensors embedded in eBikes, machine learning algorithms can identify patterns and trends in rider behavior, and use this information to suggest design improvements and optimizations. For example, machine learning algorithms could identify that riders in a particular region prefer eBikes with a specific range or battery life, and suggest design changes to meet these preferences. By optimizing eBike design in this way, manufacturers can improve customer satisfaction and loyalty, and gain a competitive edge in the market.

Another opportunity for AI in eBike manufacturing is the use of computer vision technologies to improve quality control and assurance. By using cameras and other sensors to inspect eBikes during the manufacturing process, computer vision algorithms can identify defects and inconsistencies in real-time, and alert manufacturers to potential issues before they become major problems. This can help to reduce waste, improve product quality, and enhance customer satisfaction.

AI can also be used to improve supply chain management and logistics in eBike manufacturing. By analyzing data from suppliers, manufacturers, and logistics providers, AI-powered systems can optimize production schedules, minimize lead times, and reduce transportation costs. This can help to improve efficiency, reduce waste, and increase profitability for manufacturers, while also ensuring that customers receive their eBikes in a timely and efficient manner.

In addition to these opportunities and innovations, AI can also be used to improve sustainability in eBike manufacturing. By optimizing production processes, reducing waste, and improving energy efficiency, AI can help manufacturers to reduce their carbon footprint and contribute to a more sustainable future. This can be particularly important for eBike manufacturers, who are often focused on producing environmentally-friendly products that promote sustainable transportation.

In conclusion, the future of AI in eBike manufacturing is bright and full of potential. By embracing emerging trends and innovations, manufacturers can improve efficiency, productivity, and product quality, while also enhancing customer satisfaction and contributing to a more sustainable future. As AI technologies continue to advance, it is likely that we will see even more exciting and innovative applications of AI in eBike manufacturing, offering numerous benefits for manufacturers and consumers alike.