Why Brake Fluid Matters: The Science Behind Hydraulic Braking

Hydraulic braking systems rely on a critical component to function effectively: brake fluid. This viscous liquid plays a vital role in transferring pressure from the brake lever to the brake caliper, enabling riders to slow down or come to a stop with precision and confidence. In addition to its primary function, brake fluid helps to prevent corrosion within the braking system, protecting expensive components from damage and ensuring a longer lifespan.

The importance of brake fluid cannot be overstated, particularly when it comes to cycle hydraulic brake fluid. Using low-quality or contaminated brake fluid can have disastrous consequences. Corrosion and wear on moving parts can lead to a loss of braking power, making it difficult to control the bike. In extreme cases, this can result in accidents or injuries. Furthermore, contaminated brake fluid can cause damage to the brake system, leading to costly repairs or even requiring a complete overhaul.

Given the critical role that brake fluid plays in hydraulic braking systems, it’s essential to understand its properties and characteristics. By selecting the right cycle hydraulic brake fluid for your bike and maintaining it properly, you can ensure optimal brake performance, reduce the risk of accidents, and prolong the lifespan of your braking system. In the following sections, we’ll delve deeper into the world of hydraulic brake fluid, exploring the different types available, how to maintain and troubleshoot your brakes, and expert tips for getting the most out of your hydraulic brakes.

Choosing the Right Hydraulic Brake Fluid for Your Cycle

When it comes to selecting the right hydraulic brake fluid for your cycle, there are several options to consider. The three main types of hydraulic brake fluids are mineral oil, synthetic oil, and DOT fluid. Each type has its own unique characteristics, advantages, and disadvantages, making it essential to understand their differences to make an informed decision.

Mineral oil-based brake fluids are a popular choice among cyclists due to their affordability and compatibility with most brake systems. However, they can be prone to absorbing moisture, which can lead to a decrease in braking performance over time. Synthetic oil-based brake fluids, on the other hand, offer superior performance and durability, but are generally more expensive than mineral oil-based fluids. DOT fluid, which is commonly used in automotive applications, is also suitable for cycle hydraulic brake fluid systems, but may not be compatible with all brake components.

When selecting a cycle hydraulic brake fluid, it’s essential to consider the specific demands of your riding style and the conditions you’ll be riding in. For example, if you’re a downhill mountain biker, you may require a brake fluid with high heat resistance and durability. On the other hand, if you’re a road cyclist, a brake fluid with low viscosity and high lubricity may be more suitable. By understanding the pros and cons of each type of brake fluid, you can make an informed decision and ensure optimal brake performance for your cycle.

How to Check and Maintain Your Hydraulic Brake Fluid

Regular maintenance is crucial to ensure optimal brake performance and prevent brake fluid-related issues. Here’s a step-by-step guide on how to inspect brake fluid levels, check for contamination, and perform routine maintenance tasks for your cycle hydraulic brake fluid system:

1. Check Brake Fluid Levels: Locate the brake fluid reservoir and inspect the fluid level. The level should be between the minimum and maximum marks on the reservoir. If the level is low, top it off with the recommended cycle hydraulic brake fluid type.

2. Inspect for Contamination: Look for signs of contamination, such as dirt, debris, or water in the brake fluid. If you notice any contaminants, it’s essential to flush and replace the brake fluid to prevent corrosion and damage to the brake system.

3. Check Brake Fluid Color and Consistency: The brake fluid should be clear or light yellow in color. If it’s dark or murky, it may be a sign of contamination or degradation. Check the consistency by tilting the reservoir. If the fluid flows smoothly and evenly, it’s a good indication of its quality.

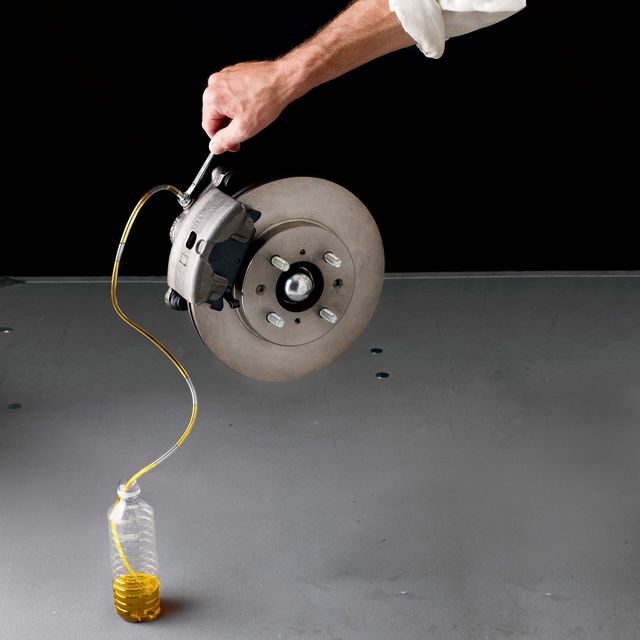

4. Perform Routine Bleeding: Bleeding your hydraulic brakes regularly can help remove air bubbles and prevent spongy brakes. Use a brake bleeding kit specifically designed for your cycle’s brake system, and follow the manufacturer’s instructions.

5. Replace Brake Pads and Rotors: Worn-out brake pads and rotors can affect brake performance and lead to premature wear on other components. Replace them according to the manufacturer’s recommended schedule or when you notice signs of wear.

By following these simple steps, you can ensure your cycle hydraulic brake fluid system is functioning optimally, providing you with confidence and control on the road or trail.

Top-Rated Hydraulic Brake Fluids for Cycles: A Product Review

When it comes to selecting the right hydraulic brake fluid for your cycle, there are numerous options available on the market. To help you make an informed decision, we’ve reviewed and compared popular hydraulic brake fluids from reputable brands, including Magura, Shimano, and SRAM.

Magura Royal Blood Hydraulic Brake Fluid: This high-performance brake fluid is designed for extreme cycling conditions, offering excellent heat resistance and durability. Its unique formula reduces the risk of brake fade and ensures consistent braking performance.

Shimano Mineral Oil Hydraulic Brake Fluid: Shimano’s mineral oil-based brake fluid is a popular choice among cyclists, offering a balance of performance and affordability. It’s compatible with most Shimano brake systems and provides reliable braking performance in various weather conditions.

SRAM DOT 5.1 Hydraulic Brake Fluid: SRAM’s DOT 5.1 brake fluid is a high-performance option designed for use in SRAM’s hydraulic brake systems. It offers excellent heat resistance, corrosion protection, and durability, making it an ideal choice for demanding cycling applications.

Comparison and Recommendation: When choosing a cycle hydraulic brake fluid, consider the specific demands of your riding style and the conditions you’ll be riding in. If you’re a downhill mountain biker, Magura’s Royal Blood may be the best option. For road cyclists, Shimano’s mineral oil-based brake fluid could be the way to go. If you’re using a SRAM brake system, their DOT 5.1 brake fluid is a top choice.

Regardless of the brand or type, it’s essential to use a high-quality cycle hydraulic brake fluid that meets the manufacturer’s specifications to ensure optimal brake performance and safety.

Common Brake Fluid-Related Issues and How to Troubleshoot Them

Hydraulic brake fluid is a critical component of a cycle’s braking system, but it can also be a source of frustration when issues arise. In this section, we’ll identify common problems associated with hydraulic brake fluid and provide troubleshooting tips and solutions to help cyclists diagnose and fix these issues.

Spongy Brakes: Spongy brakes can be a sign of air in the brake system or contaminated brake fluid. To troubleshoot, check the brake fluid level and look for signs of contamination. If the fluid is dirty or low, replace it with fresh cycle hydraulic brake fluid and bleed the brakes to remove any air bubbles.

Fluid Leaks: Fluid leaks can occur due to worn-out seals or damaged brake lines. Inspect the brake system for signs of wear or damage and replace any faulty components. Make sure to use the correct type of cycle hydraulic brake fluid for your brake system to prevent compatibility issues.

Corrosion: Corrosion can occur when brake fluid comes into contact with moisture or oxygen. To prevent corrosion, use a high-quality cycle hydraulic brake fluid that is resistant to corrosion and moisture. Regularly inspect the brake system for signs of corrosion and replace any affected components.

Brake Fade: Brake fade can occur when the brake fluid overheats, causing it to lose its viscosity and effectiveness. To prevent brake fade, use a high-performance cycle hydraulic brake fluid that is designed to withstand high temperatures. Make sure to regularly inspect and maintain the brake system to prevent overheating.

By understanding the common issues associated with hydraulic brake fluid and knowing how to troubleshoot them, cyclists can ensure their brakes are functioning optimally and safely. Remember to always use high-quality cycle hydraulic brake fluid and follow proper maintenance procedures to prevent brake fluid-related issues.

The Importance of Bleeding Your Hydraulic Brakes

Bleeding your hydraulic brakes is a crucial maintenance task that ensures optimal brake performance and safety. In this section, we’ll explain the process of bleeding hydraulic brakes and why it’s essential for maintaining your cycle’s braking system.

Bleeding hydraulic brakes involves removing air bubbles and contaminants from the brake system, which can affect brake performance and lead to safety issues. Air bubbles can enter the system when brake pads are replaced, or when the brake fluid level is low. If left unchecked, these air bubbles can cause spongy brakes, reduced braking power, and even brake failure.

To bleed your hydraulic brakes, you’ll need a few tools, including a brake bleeding kit, a clean rag, and some fresh cycle hydraulic brake fluid. Start by attaching the bleeding kit to the brake caliper and opening the bleed screw. Then, slowly pump the brake lever to push the brake fluid through the system, allowing any air bubbles to escape. Repeat this process several times until the brake fluid flows cleanly and consistently.

It’s essential to use the correct type of cycle hydraulic brake fluid for your brake system, as specified by the manufacturer. Using the wrong type of fluid can lead to compatibility issues and affect brake performance. Always refer to your cycle’s manual for specific guidance on bleeding and maintaining your hydraulic brakes.

Regular bleeding of your hydraulic brakes can help prevent common issues such as spongy brakes, fluid leaks, and corrosion. By keeping your brake system clean and free of contaminants, you can ensure optimal brake performance and safety on the road or trail.

Hydraulic Brake Fluid Safety Precautions: What You Need to Know

When working with cycle hydraulic brake fluid, it’s essential to take necessary safety precautions to avoid potential hazards. Hydraulic brake fluid can be harmful if not handled properly, and cyclists should be aware of the risks associated with its use.

One of the primary concerns when handling hydraulic brake fluid is skin and eye irritation. Cycle hydraulic brake fluid can cause skin irritation, including redness, itching, and rashes, while eye exposure can lead to irritation, blurred vision, and even corneal damage. To minimize the risk of skin and eye irritation, always wear protective gear, including gloves, safety glasses, and a face mask, when working with hydraulic brake fluid.

Another important safety consideration is the proper disposal of used hydraulic brake fluid. Cycle hydraulic brake fluid should never be poured down the drain or disposed of in regular trash, as it can contaminate waterways and harm the environment. Instead, take used brake fluid to a local recycling center or an authorized brake fluid disposal facility.

When handling hydraulic brake fluid, it’s also crucial to follow proper storage and handling procedures. Store cycle hydraulic brake fluid in a cool, dry place, away from direct sunlight and heat sources. Always check the brake fluid for signs of contamination or degradation before use, and never mix different types of brake fluid.

By taking these safety precautions seriously, cyclists can minimize the risks associated with hydraulic brake fluid and ensure a safe and enjoyable riding experience. Remember to always follow the manufacturer’s instructions and guidelines for handling and disposing of cycle hydraulic brake fluid.

Optimizing Brake Performance: Tips and Tricks from the Pros

When it comes to getting the most out of your hydraulic brakes, there are several expert techniques and tips that can help you optimize brake performance. By following these pro tips, you can ensure your cycle hydraulic brake fluid is working at its best, providing you with reliable and consistent braking power.

One key area to focus on is brake pad selection. Choosing the right brake pads for your cycle can make a significant difference in brake performance. Look for brake pads specifically designed for your type of cycling, whether it’s road, mountain, or cross-country. Additionally, consider upgrading to high-performance brake pads for improved stopping power and durability.

Rotor maintenance is another crucial aspect of optimizing brake performance. Regularly clean and inspect your rotors to ensure they’re free from debris and corrosion. Use a soft cloth and a gentle cleaning solution to avoid damaging the rotor surface. Also, consider upgrading to high-performance rotors for improved heat dissipation and braking power.

Fine-tuning brake lever adjustment is also essential for optimal brake performance. Adjust the brake lever to your preferred feel and sensitivity, taking into account factors such as finger size and riding style. Make sure the brake lever is securely attached to the handlebar and that the brake cable is properly routed and adjusted.

Finally, consider upgrading to a high-performance cycle hydraulic brake fluid for improved braking power and consistency. Look for brake fluids specifically designed for your type of cycling, and follow the manufacturer’s guidelines for use and maintenance.

By following these expert tips and techniques, you can optimize your hydraulic brake performance and enjoy a safer and more enjoyable riding experience. Remember to always follow proper safety precautions when working with cycle hydraulic brake fluid, and consult your cycle’s manual for specific guidance on brake maintenance and adjustment.