Why Accurate Wheel Size Measurements Matter

Accurate wheel size measurements are crucial for a variety of reasons, primarily related to safety, performance, and compatibility with vehicles or equipment. When wheel size is measured correctly, it ensures proper fitment, reducing the risk of accidents or damage caused by wheels that are too small or too large. Moreover, precise wheel size measurements can optimize vehicle performance, enabling smoother rides, better handling, and improved fuel efficiency. In addition, correctly sized wheels can enhance compatibility with specific vehicles or equipment, ensuring optimal functionality and longevity.

Tools and Equipment Needed for Measuring Wheel Size

Measuring wheel size accurately requires the use of appropriate tools and equipment. Some of the most common tools used for measuring wheel size include measuring tapes, vernier calipers, and wheel diameter gauges. When selecting these tools, it’s essential to choose those that are accurate, durable, and easy to use. Measuring tapes, for instance, should be long enough to measure the entire wheel diameter, while vernier calipers should have a precision of at least 0.05 millimeters. Wheel diameter gauges, on the other hand, should be specifically designed for measuring wheel size and should be calibrated regularly to ensure accuracy.

To use these tools effectively, it’s essential to follow best practices for measuring wheel size. For instance, when measuring wheel diameter, it’s crucial to locate the wheel’s centerline accurately and to take measurements at multiple points around the wheel to ensure consistency. Similarly, when measuring wheel width, it’s essential to locate the wheel’s inner and outer edges accurately and to take measurements at multiple points along the wheel’s width to ensure consistency.

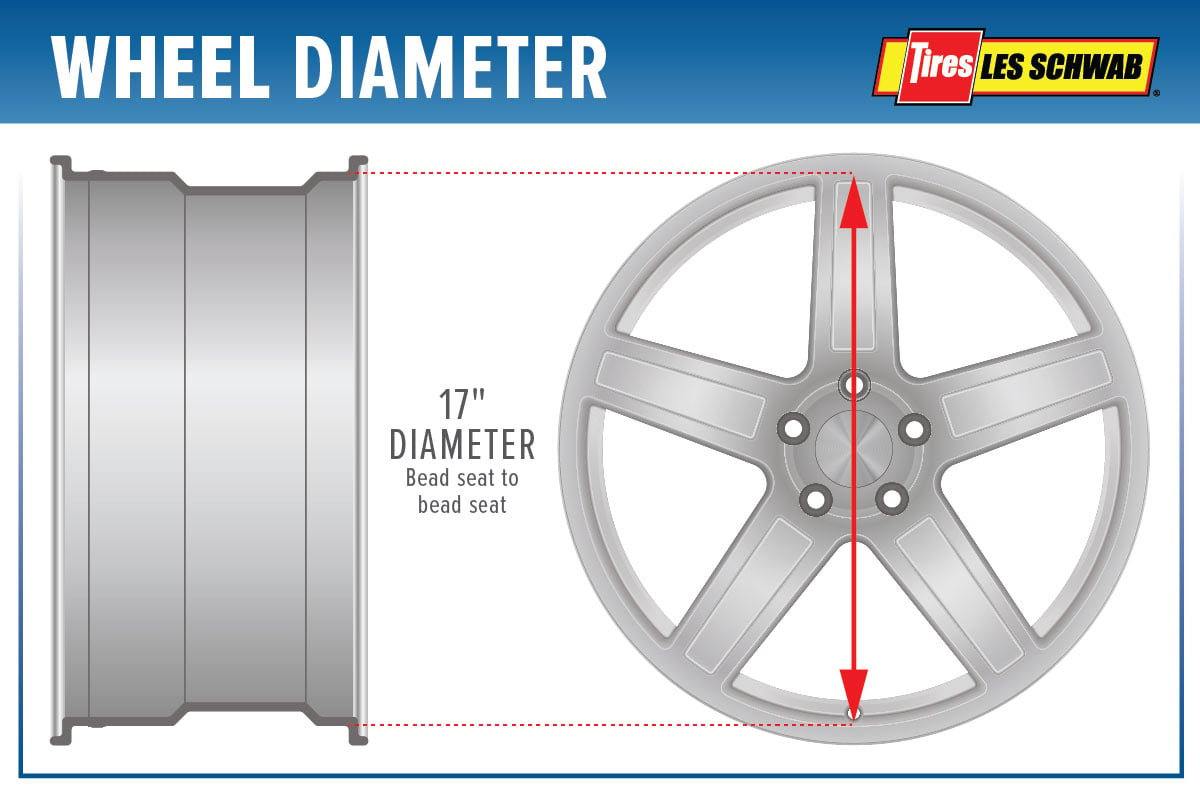

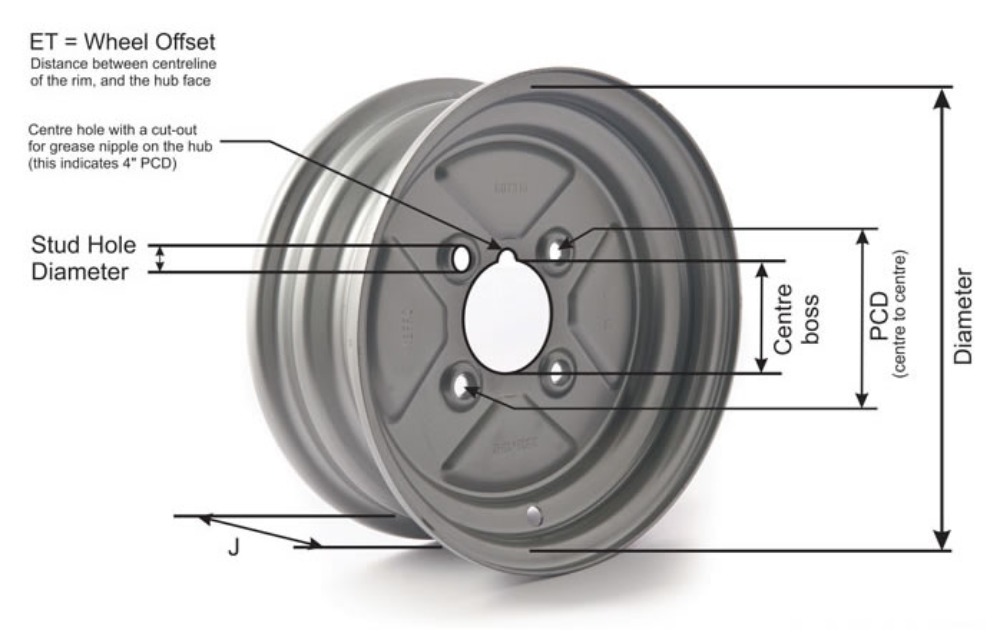

Measuring Wheel Diameter: The First Step in Determining Wheel Size

Measuring wheel diameter is the first step in accurately determining wheel size. To measure wheel diameter, you’ll need to locate the wheel’s centerline accurately. This can be done by measuring the distance from the wheel’s inner edge to its outer edge at multiple points around the wheel. Once you’ve located the centerline, you can take accurate measurements of the wheel’s diameter using the appropriate tools.

Measuring tapes and vernier calipers are commonly used to measure wheel diameter. When using a measuring tape, it’s essential to ensure that the tape is taut and level with the wheel’s surface. Measure from the wheel’s inner edge to its outer edge at multiple points around the wheel to ensure consistency. When using vernier calipers, it’s essential to ensure that the calipers are placed firmly against the wheel’s surface and that the jaws are aligned with the wheel’s inner and outer edges. Take multiple measurements around the wheel to ensure consistency.

When measuring wheel diameter, it’s essential to account for any variations in wheel shape or profile. Some wheels may have a concave or convex profile, which can affect the overall diameter. To account for these variations, it’s essential to take measurements at multiple points around the wheel and to use the largest diameter measurement when calculating wheel size.

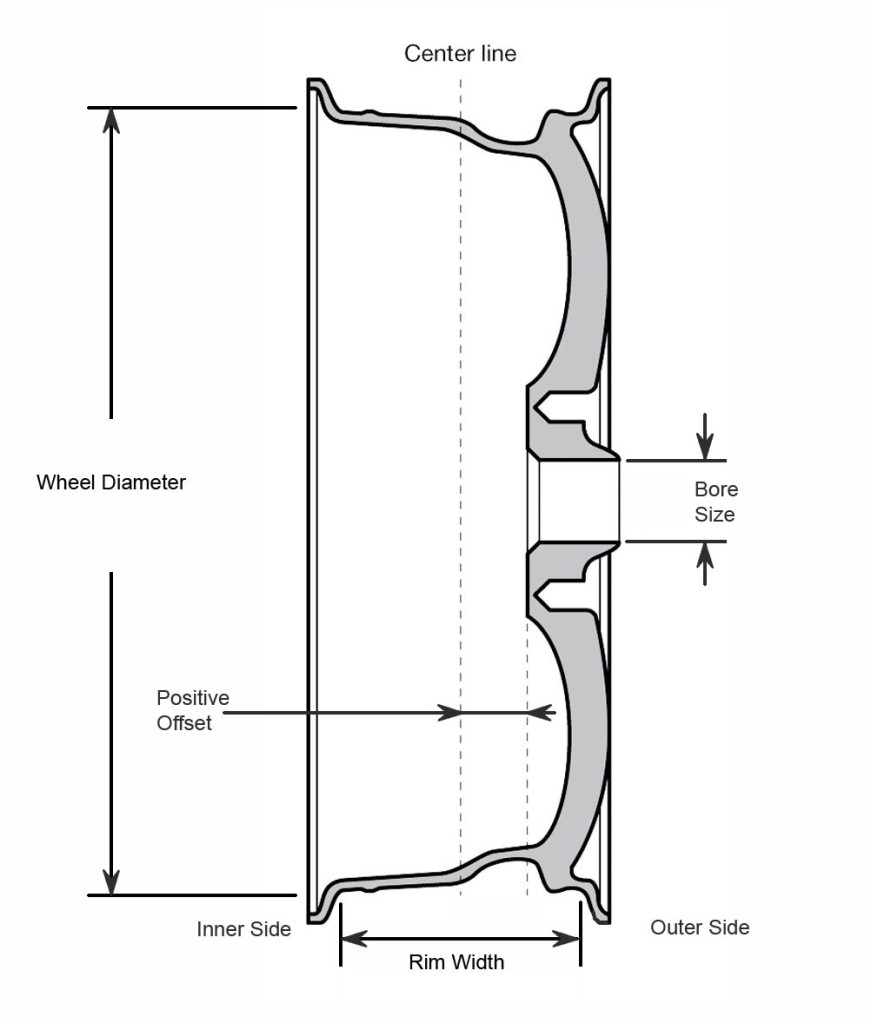

Measuring Wheel Width: The Second Step in Determining Wheel Size

Measuring wheel width is the second step in accurately determining wheel size. To measure wheel width, you’ll need to locate the wheel’s inner and outer edges accurately. This can be done by placing a straight edge or ruler against the wheel’s surface and measuring the distance between the inner and outer edges at multiple points along the wheel’s width.

When measuring wheel width, it’s essential to account for any variations in wheel shape or profile. Some wheels may have a tapered or stepped profile, which can affect the overall width. To account for these variations, it’s essential to take measurements at multiple points along the wheel’s width and to use the largest width measurement when calculating wheel size.

Measuring tapes and vernier calipers are commonly used to measure wheel width. When using a measuring tape, it’s essential to ensure that the tape is taut and level with the wheel’s surface. Measure from the wheel’s inner edge to its outer edge at multiple points along the wheel’s width to ensure consistency. When using vernier calipers, it’s essential to ensure that the calipers are placed firmly against the wheel’s surface and that the jaws are aligned with the wheel’s inner and outer edges. Take multiple measurements along the wheel’s width to ensure consistency.

When measuring wheel width, it’s essential to account for any variations in tire size or profile. Some tires may have a larger or smaller profile than others, which can affect the overall width of the wheel and tire assembly. To account for these variations, it’s essential to take measurements of both the wheel and tire assembly and to use the largest width measurement when calculating wheel size.

Calculating Wheel Circumference: The Final Step in Determining Wheel Size

Once you’ve measured the wheel diameter and width accurately, you can calculate the wheel circumference. The wheel circumference is the distance the wheel travels in one complete revolution and is an essential measurement for many real-world applications, such as calculating speed, distance, or torque.

To calculate the wheel circumference, you can use the following formula:

Circumference = π x Diameter x Width

Where:

- π (pi) is a mathematical constant approximately equal to 3.14159

- Diameter is the wheel’s overall diameter, measured in the same units as the width

- Width is the wheel’s overall width, measured in the same units as the diameter

For example, if the wheel diameter is 16 inches and the width is 7 inches, the wheel circumference would be:

Circumference = 3.14159 x 16 x 7 = 368.57 cubic inches

When calculating the wheel circumference, it’s essential to use the same units for both the diameter and width. This will ensure that the calculation is accurate and consistent.

It’s also essential to account for any variations in tire size or profile when calculating the wheel circumference. Some tires may have a larger or smaller profile than others, which can affect the overall circumference of the wheel and tire assembly. To account for these variations, it’s essential to take measurements of both the wheel and tire assembly and to use the largest circumference measurement when calculating wheel size.

Common Mistakes to Avoid When Measuring Wheel Size

Measuring wheel size accurately can be a complex process, and there are several common mistakes that can occur. Here are some tips on how to avoid these mistakes and ensure accurate wheel size measurements:

- Using inappropriate tools: Using the wrong tools for measuring wheel size can lead to inaccurate measurements. Make sure to use measuring tapes, vernier calipers, or wheel diameter gauges that are specifically designed for measuring wheel size. These tools should be calibrated regularly to ensure accuracy.

- Failing to account for tire width: Tire width can affect the overall diameter and width of the wheel and tire assembly. When measuring wheel size, it’s essential to account for any variations in tire size or profile. Take measurements of both the wheel and tire assembly and use the largest diameter and width measurements when calculating wheel size.

- Not taking accurate measurements: Inaccurate measurements can lead to incorrect wheel size calculations. When measuring wheel diameter, width, or circumference, make sure to take multiple measurements at multiple points along the wheel’s surface. Use the average of these measurements to ensure accuracy.

- Using outdated measurement standards: Wheel size measurement standards can change over time, and using outdated standards can lead to inaccurate measurements. Make sure to use the most up-to-date measurement standards and guidelines when measuring wheel size.

- Not accounting for variations in wheel shape or profile: Some wheels may have a tapered or stepped profile, which can affect the overall diameter or width. When measuring wheel size, it’s essential to account for any variations in wheel shape or profile. Take measurements at multiple points along the wheel’s surface and use the largest diameter and width measurements when calculating wheel size.

Real-World Applications of Wheel Size Measurements

Accurate wheel size measurements are essential in a variety of real-world applications, from vehicle maintenance to equipment selection and performance optimization. Here are some examples of how wheel size measurements are used in practice:

- Vehicle maintenance: Accurate wheel size measurements are essential for routine vehicle maintenance, such as tire rotation, wheel alignment, or brake repair. By measuring wheel size accurately, technicians can ensure that the correct tires and components are used, reducing the risk of accidents or damage to the vehicle.

- Equipment selection: When selecting equipment such as wheelchairs, carts, or hand trucks, it’s essential to choose components that are the correct size for the application. Accurate wheel size measurements can help ensure that the equipment is safe, efficient, and easy to use, reducing the risk of injury or damage to the equipment.

- Performance optimization: In performance-critical applications such as racing or high-performance vehicles, accurate wheel size measurements can help optimize speed, handling, and fuel efficiency. By measuring wheel size accurately, engineers and technicians can select the correct tires, wheels, and components to maximize performance and safety.

- Industrial applications: In industrial applications such as manufacturing, mining, or construction, accurate wheel size measurements are essential for selecting the correct equipment and components. By measuring wheel size accurately, operators can ensure that the equipment is safe, efficient, and durable, reducing the risk of accidents or damage to the equipment.

In each of these applications, accurate wheel size measurements are essential for ensuring safety, efficiency, and performance. By taking the time and effort to measure wheel size correctly, you can help ensure that your vehicles, equipment, and components are operating at their best, reducing the risk of accidents, damage, or injury.

Conclusion: The Importance of Accurate Wheel Size Measurements

Measuring wheel size accurately is essential for a variety of applications, from vehicle maintenance to performance optimization and equipment selection. By taking the time and effort to measure wheel size correctly, you can help ensure safety, efficiency, and performance in your vehicles, equipment, and components.

As we’ve discussed in this guide, there are several key factors to consider when measuring wheel size, including the use of appropriate tools and equipment, the importance of accounting for tire width, and the need to take accurate and consistent measurements. By avoiding common mistakes and following best practices, you can help ensure that your wheel size measurements are accurate and reliable.

In real-world applications, accurate wheel size measurements are essential for optimizing performance, reducing the risk of accidents or damage, and ensuring compatibility with vehicles or equipment. By taking the time to measure wheel size correctly, you can help ensure that your wheels, tires, and components are operating at their best, providing maximum value and utility for your investment.

In summary, accurately measuring wheel size is a critical task that requires attention to detail, careful selection of tools and equipment, and a commitment to best practices. By following the guidance provided in this guide, you can help ensure that your wheel size measurements are accurate, reliable, and useful in a variety of real-world applications.