Understanding the Basics of Mountain Bike Gearing

Mountain bikes use gearing systems to help riders tackle various terrains and inclines with ease. The primary components of a mountain bike’s gearing system include the front and rear derailleurs, chainrings, and cassettes. Front derailleurs control the chain’s movement between the chainrings, while rear derailleurs manage the chain’s movement across the cassette’s cogs. Chainrings, typically ranging from one to three, are attached to the crankset and help determine the bike’s gear range. Cassettes, located on the rear wheel hub, consist of multiple cogs that work in conjunction with the chainrings to provide a wide range of gears. Regular gear adjustments are essential for optimal performance and longevity of the drivetrain, ensuring smooth and precise gear shifts.

Tools Required for Adjusting Mountain Bike Gears

To accurately adjust the gears on a mountain bike, you’ll need a few essential tools. A bike stand is crucial for keeping the bike stable and secure during the adjustment process. Hex wrenches, specifically 4mm, 5mm, and possibly 6mm, are necessary for tightening and loosening various bolts and screws on the derailleurs and shifters. Cable cutters are required for cleanly trimming and sealing the gear cables after adjustments. A derailleur alignment gauge or a ruler can help ensure accurate derailleur alignment. Investing in high-quality tools can lead to more precise and long-lasting adjustments, ultimately benefiting the overall performance and longevity of the drivetrain.

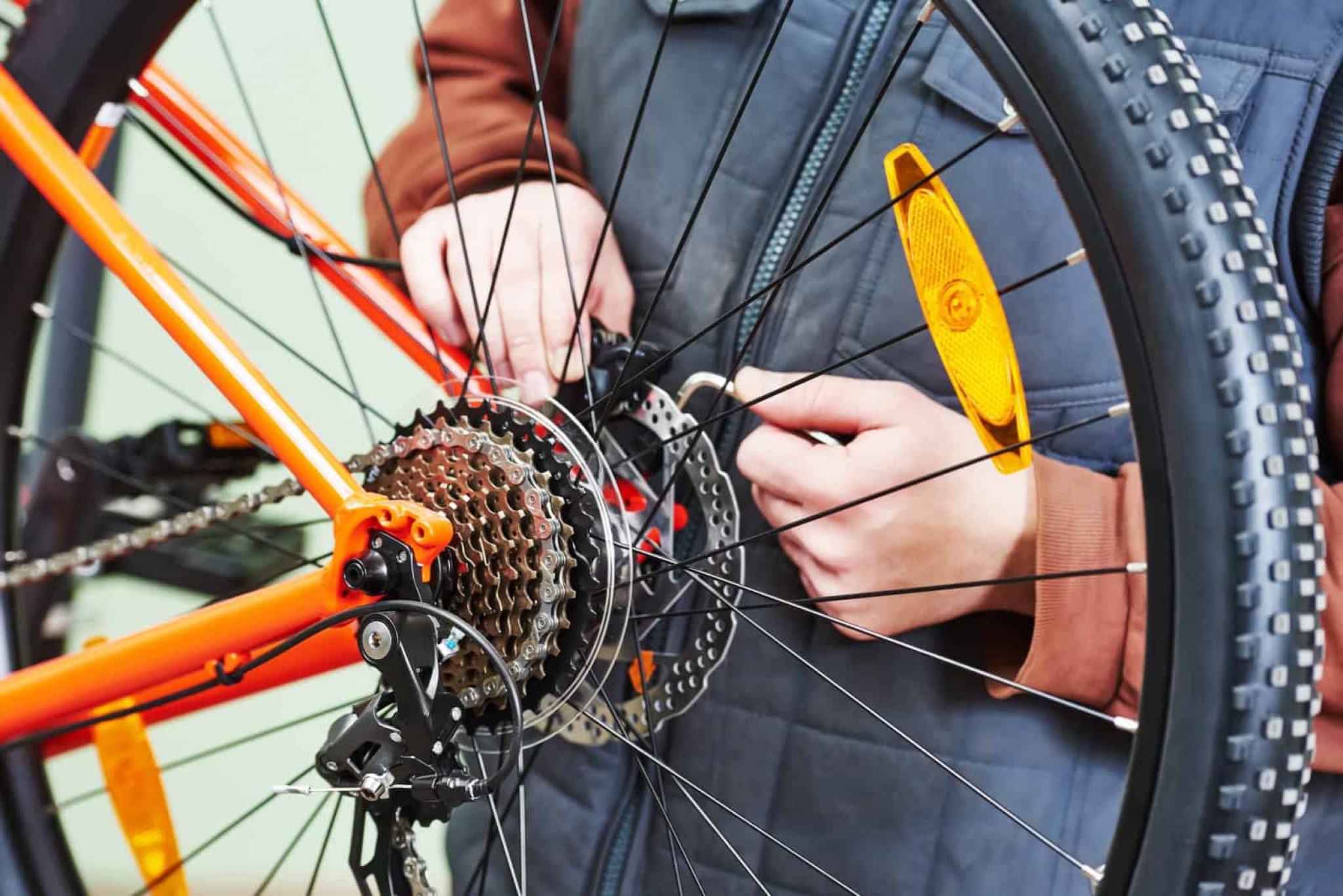

Inspection and Cleaning of the Drivetrain

Before making any gear adjustments on a mountain bike, it’s essential to inspect and clean the drivetrain. Over time, dirt, debris, and grime can accumulate on the chainrings, cassette, and derailleurs, affecting the accuracy of gear shifts. To clean the drivetrain, start by shifting the bike into the smallest chainring and smallest cog to create slack in the chain. Then, using a brush and a degreaser, scrub the chainrings, cassette, and derailleurs to remove dirt and debris. Rinely the components thoroughly with water and allow them to dry completely. After cleaning, apply a light layer of lubricant to the chain to ensure smooth and quiet operation. Regular cleaning and maintenance of the drivetrain can significantly improve gear shifting performance and extend the lifespan of the drivetrain components.

Checking and Adjusting the Limit Screws

Limit screws play a critical role in preventing the chain from falling off the smallest and largest chainrings or cogs during gear shifts. These screws, typically located on the rear derailleur, control the maximum movement of the derailleur in both inward and outward directions. To check and adjust the limit screws, follow these steps:

- Shift the bike into the smallest chainring and smallest cog. Locate the low limit screw, often marked with an “L” or an arrow pointing towards the smallest cog. Slowly turn the screw clockwise until the derailleur cage barely touches the cog. Then, turn the screw counterclockwise in small increments until the derailleur cage no longer touches the cog. This adjustment ensures that the chain does not fall off the smallest cog during downshifts.

- Shift the bike into the largest chainring and largest cog. Locate the high limit screw, often marked with a “H” or an arrow pointing towards the largest cog. Follow the same process as in step 1, adjusting the screw until the derailleur cage barely touches the cog and then backing it off slightly. This adjustment ensures that the chain does not fall off the largest cog during upshifts.

- Test the limit screw adjustments by shifting through all the gears. Make any necessary adjustments to ensure smooth and safe gear shifts without the chain falling off the chainrings or cogs.

Regularly checking and adjusting the limit screws can significantly improve gear shifting performance and prevent costly drivetrain damage. Always double-check limit screw adjustments after cleaning or replacing drivetrain components.

Cable Tension and Indexing Adjustments

Cable tension and indexing play a crucial role in accurate gear shifts on a mountain bike. Over time, cable tension can loosen, leading to inconsistent or sluggish gear shifts. Indexing adjustments ensure that the derailleur moves the correct amount for each gear shift. To adjust cable tension and indexing, follow these steps:

- Shift the bike into the smallest chainring and smallest cog. Locate the barrel adjuster on the shifter or near the derailleur. If the gear shift is too slow, turn the barrel adjuster counterclockwise in small increments until the shift becomes quicker and more precise.

- Shift the bike into the largest chainring and largest cog. If the gear shift is too fast or results in an overlapping shift, turn the barrel adjuster clockwise in small increments until the shift becomes more controlled.

- Test the cable tension and indexing adjustments by shifting through all the gears. Make any necessary adjustments to ensure smooth and accurate gear shifts.

- If further tension adjustments are required, use a cable clamp to hold the cable taut while making adjustments at the derailleur. Tighten the cable by turning the pinch bolt clockwise, ensuring that the cable is not overly tightened, which can cause damage to the components.

Regularly checking and adjusting cable tension and indexing can significantly improve gear shifting performance and reduce wear and tear on the drivetrain components. Always double-check cable tension and indexing adjustments after cleaning or replacing drivetrain components.

Derailleur Alignment and Adjustment

Proper derailleur alignment is essential for precise gear shifts and smooth operation. An improperly aligned derailleur can cause the chain to rub against the cassette or chainstay, leading to excessive wear and noise. To align the derailleur, follow these steps:

- Shift the bike into the smallest chainring and smallest cog. Locate the derailleur hanger, which is typically a replaceable component that attaches the derailleur to the frame. Inspect the hanger for any signs of damage or bending.

- If the hanger is damaged or bent, replace it or take the bike to a professional mechanic for repair. A damaged hanger can lead to poor shifting performance and increased wear on the drivetrain components.

- Attach a derailleur alignment gauge or a ruler to the largest cog on the cassette. Align the gauge so that it is parallel to the largest cog. Alternatively, use a straightedge to ensure that the derailleur pulley is aligned with the largest cog.

- Adjust the derailleur by loosening the derailleur mounting bolt and using a hex wrench to turn the limit screws. The high gear screw, often marked with an “H,” controls the movement of the derailleur towards the largest cog. The low gear screw, marked with an “L,” controls the movement of the derailleur towards the smallest cog. Turn the screws in small increments until the derailleur pulley is aligned with the largest cog.

- Tighten the derailleur mounting bolt and test the alignment by shifting through all the gears. Make any necessary adjustments to ensure smooth and precise gear shifts.

Regularly inspecting and adjusting the derailleur alignment can significantly improve gear shifting performance and extend the lifespan of the drivetrain components. Always double-check derailleur alignment after cleaning or replacing drivetrain components.

Testing and Fine-Tuning the Gear Shifts

After making any adjustments to the gears on your mountain bike, it’s essential to test and fine-tune the gear shifts for optimal performance. Follow these steps to ensure smooth and precise gear shifts:

- Shift the bike into the smallest chainring and smallest cog. Slowly pedal the bike while shifting through all the gears, paying attention to the smoothness and precision of each shift.

- If you notice any issues, such as slow shifts, overlapping shifts, or chain rubbing, make any necessary adjustments to the cable tension, indexing, or limit screws. Repeat the testing process until the gear shifts are smooth and precise.

- Test the gear shifts under various loads and terrains, such as climbing hills or riding on rough surfaces. This testing will help ensure that the gear adjustments are consistent and reliable in different riding conditions.

- Consider having a friend or riding partner observe the gear shifts while you ride. A second pair of eyes can help identify any issues that you may have missed during your testing.

Regularly testing and fine-tuning the gear shifts can significantly improve your mountain biking experience, ensuring smooth and precise gear shifts for optimal performance and longevity of the drivetrain. Always double-check gear adjustments after cleaning or replacing drivetrain components.

Maintaining the Adjusted Gears

Maintaining the adjusted gears on your mountain bike is crucial for consistent gear shifting performance and the longevity of the drivetrain. Follow these tips and recommendations to keep your gears in top condition:

- Regularly clean and lubricate the chain, chainrings, and cassette to remove dirt, debris, and grime that can affect gear shifting performance. Use a degreaser and a chain cleaning tool to remove stubborn grime, then apply a high-quality chain lubricant to ensure smooth and quiet operation.

- Inspect the cables and housing for any signs of wear, damage, or corrosion. Replace any damaged or worn-out components to ensure optimal gear shifting performance. Regularly tightening the cable housing can also help maintain consistent gear shifting performance.

- Check the limit screws and adjust them as necessary to prevent the chain from falling off the smallest and largest chainrings or cogs. Regularly inspect the derailleur hanger for any signs of damage or bending, and replace it if necessary.

- Perform routine inspections of the derailleur alignment and adjust as necessary to ensure precise gear shifts. Use a derailleur alignment gauge or a ruler to check the alignment and make any necessary adjustments.

- Consider using a high-quality, synthetic grease on the pivot points of the derailleur to reduce wear and ensure smooth operation. Regularly inspect and clean the derailleur pulleys to remove any built-up debris or grime.

By following these maintenance tips and recommendations, you can ensure consistent gear shifting performance and extend the lifespan of your mountain bike’s drivetrain components. Regular cleaning, lubrication, and inspection are key to maintaining the adjusted gears and enjoying a smooth and enjoyable ride.