Understanding the Brake System: How Air Enters and Affects Performance

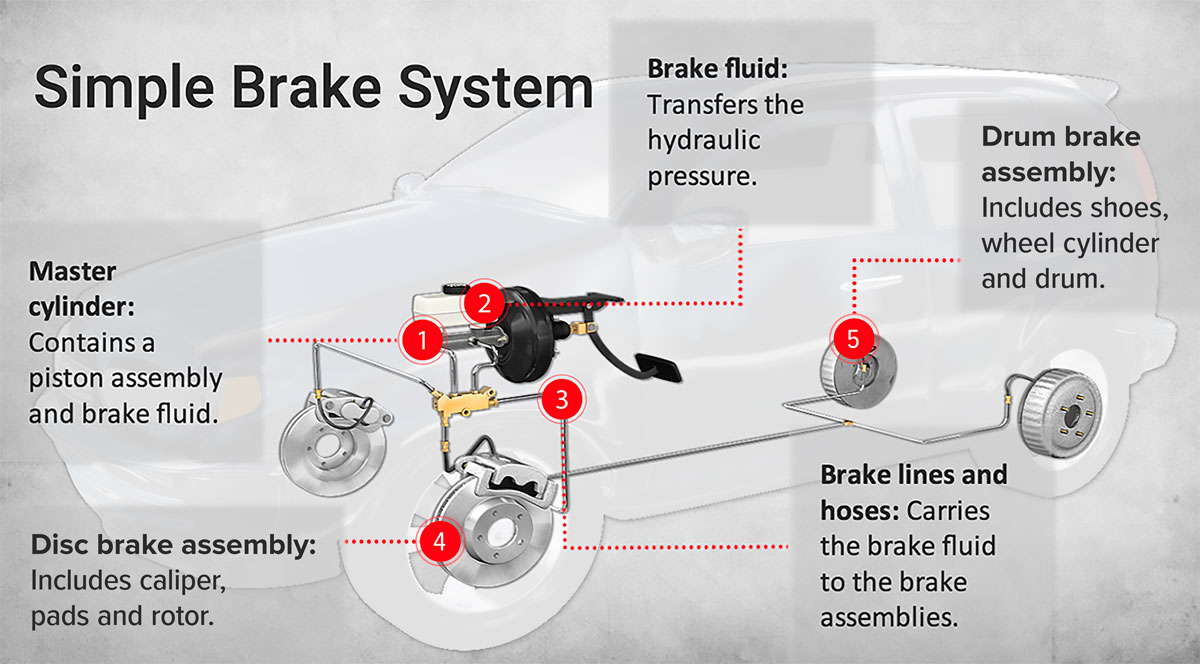

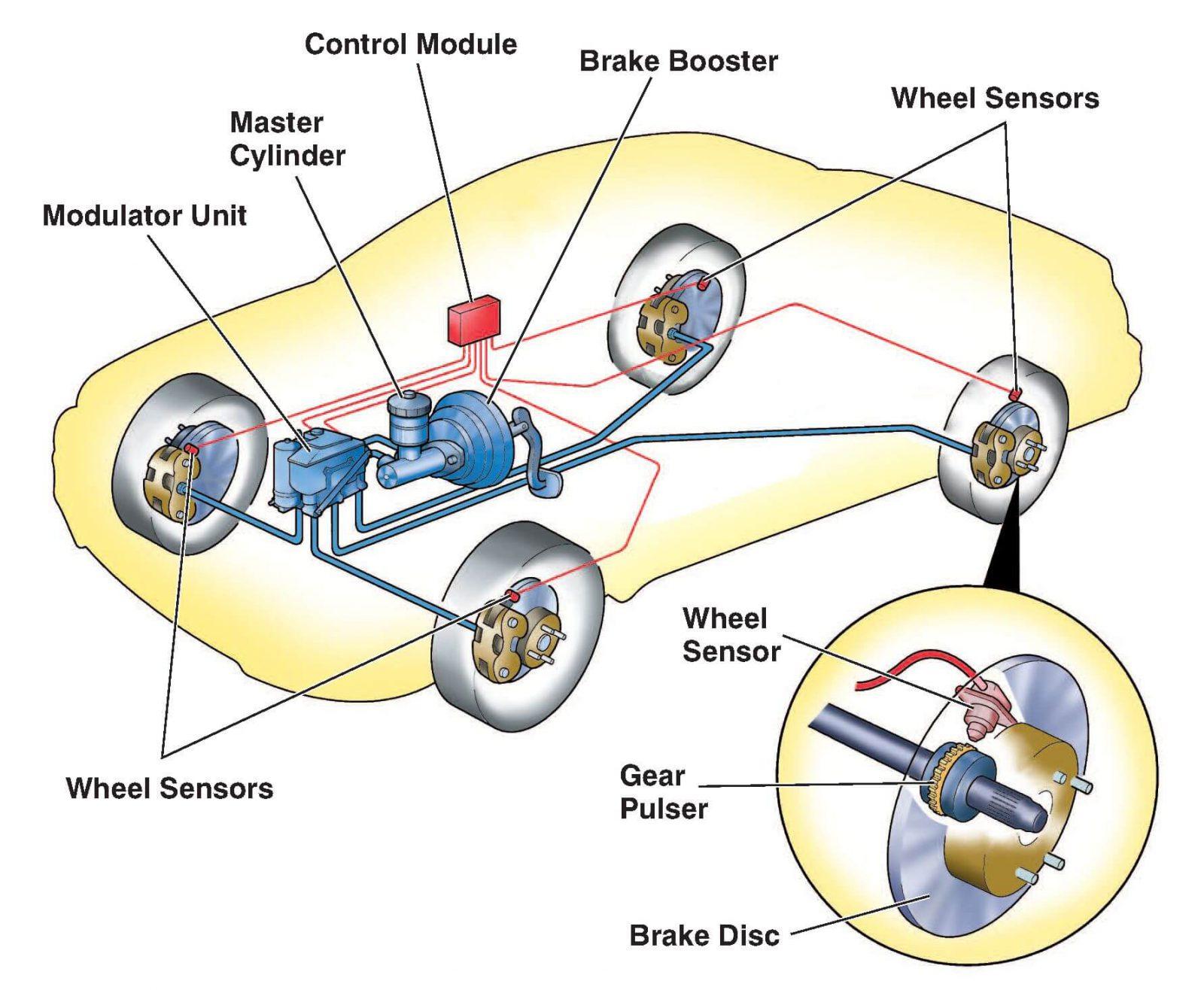

Hydraulic brake systems rely on a sealed, pressurized fluid system to transfer force from the brake pedal to the brake pads, allowing your vehicle to slow down or stop. However, air can enter the brake lines due to various reasons, such as worn-out seals, damaged lines, or improper maintenance. This intrusion of air creates bubbles in the brake fluid, reducing the effectiveness of the hydraulic pressure and leading to a spongy or unresponsive brake pedal. Consequently, bleeding the brakes is crucial to remove trapped air and maintain optimal brake performance and safety.

Gathering Necessary Tools and Materials: A Checklist for Success

To ensure a smooth and efficient brake bleeding process, gather all necessary tools and materials beforehand. Here’s a comprehensive checklist:

- High-quality brake fluid: Select a DOT 3, 4, or 5.1 brake fluid, depending on your vehicle’s requirements. Always use a new, sealed container to avoid contamination.

- Clean containers or bottles: Repurpose empty plastic bottles to collect used brake fluid. Ensure they are thoroughly cleaned and labeled for proper disposal.

- Clear plastic tubing: Transparent tubing allows you to monitor the brake fluid flow and identify any air bubbles during the bleeding process.

- Brake bleed kit: Depending on the chosen method, invest in a quality manual, pressure, or vacuum brake bleed kit. These kits often include adapters and hoses compatible with various vehicle makes and models.

- Protective gloves and eyewear: Safeguard your skin and eyes from potential brake fluid contamination and irritation.

- Wrenches and socket sets: Securely loosen and tighten brake line connections using appropriate wrenches and socket sets.

- A stable and secure vehicle lift or jack stands: Ensure your safety and proper access to the brake system components by using reliable lifting equipment.

- Clean rags and paper towels: Keep your workspace clean and organized by having an ample supply of rags and paper towels on hand.

Preparing Your Vehicle: Step-by-Step Instructions for Pre-Bleeding Procedures

Before starting the brake bleeding process, it’s crucial to prepare your vehicle properly to ensure safety and efficiency. Follow these steps:

- Find a suitable location: Choose a spacious, well-ventilated area with a flat, stable surface for your vehicle. This will help prevent accidents and make it easier to maneuver around your vehicle during the brake bleeding process.

- Secure the vehicle: Apply the parking brake and engage the transmission in park (for automatic vehicles) or first gear (for manual vehicles). This will help prevent the vehicle from moving during the brake bleeding process.

- Lift the vehicle safely: Use a reliable vehicle lift or jack stands to raise your vehicle off the ground. Ensure the lifting points are specified in your vehicle’s owner’s manual to avoid damaging the vehicle. Once lifted, double-check that the vehicle is secure before proceeding.

- Set up a clean work environment: Place a drop cloth or newspapers underneath the vehicle to catch any spilled brake fluid. This will help keep your workspace clean and prevent contamination of the surrounding area.

- Gather all necessary tools and materials: Ensure you have all the required tools and materials for bleeding air out of brakes. Refer to our detailed checklist in the article for a comprehensive list of items needed for a smooth and efficient process.

- Locate the brake bleed screws: Familiarize yourself with the brake system components and locate the brake bleed screws on each wheel. This will help you efficiently access these components during the brake bleeding process.

Selecting the Right Brake Bleeding Method: Manual, Pressure, or Vacuum Techniques

When it comes to bleeding air out of brakes, various methods are available, each with its advantages and disadvantages. Understanding these differences will help you choose the most suitable option for your specific situation. Here, we discuss manual, pressure, and vacuum techniques:

Manual Brake Bleeding

Manual brake bleeding is the most traditional method, requiring a helper to apply and release the brake pedal while you open and close the brake bleed screws. This method is time-consuming and prone to human error, but it’s affordable and accessible for most vehicle owners.

Pressure Brake Bleeding

Pressure brake bleeding uses a specialized kit to apply pressure to the brake fluid reservoir, forcing the air out of the brake lines. This method is faster and more efficient than manual bleeding, but it requires an initial investment in a pressure bleeding kit. Additionally, it may not be suitable for beginners due to the potential for overpressurization and damage to the brake system.

Vacuum Brake Bleeding

Vacuum brake bleeding uses a vacuum pump to draw brake fluid from the bleed screws, pulling air out of the brake lines. This method is also faster and more efficient than manual bleeding, and it’s less prone to overpressurization issues compared to pressure bleeding. However, vacuum bleeding kits can be more expensive than pressure bleeding kits, and they may not be as accessible for some vehicle owners.

Consider factors such as your budget, experience level, and available tools when selecting the right brake bleeding method for your needs. Each method has its merits, so choose the one that best aligns with your unique situation and skillset.

Following a Systematic Approach: A Step-by-Step Guide to Bleeding Air Out of Brakes

To ensure a smooth and efficient brake bleeding process, it’s essential to maintain a systematic and organized approach. Here’s a comprehensive, easy-to-follow guide on bleeding air out of brakes, using the chosen method from the previous section:

- Fill the brake fluid reservoir: Before starting the brake bleeding process, ensure the brake fluid reservoir is filled to the recommended level with fresh, clean brake fluid. This will help maintain proper hydraulic pressure and prevent the introduction of additional air into the system.

- Locate the brake bleed screws: Familiarize yourself with the brake system components and locate the brake bleed screws on each wheel. This will help you efficiently access these components during the brake bleeding process.

- Prepare the brake bleeding kit and tools: Set up your chosen brake bleeding kit and gather any necessary tools, such as wrenches or socket sets, for opening and closing the brake bleed screws.

- Begin the brake bleeding process: Start with the wheel farthest from the brake fluid reservoir and follow the specific instructions for your chosen brake bleeding method. Be sure to maintain a consistent pace and pressure throughout the process, and avoid introducing air back into the system.

- Check for proper brake function: After bleeding each wheel, test the brake function by pressing the brake pedal. You should feel a firm, responsive pedal with no sponginess or air bubbles in the brake fluid. If issues persist, continue the brake bleeding process until the brakes function properly.

- Repeat the process for all wheels: Once you’ve completed the brake bleeding process for one wheel, move on to the next wheel, following the same steps and maintaining a systematic approach.

- Refill the brake fluid reservoir: After bleeding all wheels, top off the brake fluid reservoir with fresh brake fluid. Dispose of any used brake fluid properly, following local regulations and guidelines.

- Test drive and post-bleeding maintenance: Once the brake bleeding process is complete, lower your vehicle safely and perform a test drive to ensure proper brake function. After the test drive, perform post-bleeding maintenance checks, adjustments, and follow-up procedures as necessary to ensure long-term brake performance and safety.

Troubleshooting Common Issues: Identifying and Addressing Problems During the Brake Bleeding Process

Even with a systematic approach, challenges may arise during the brake bleeding process. Anticipating these issues and having practical solutions at hand will help you overcome obstacles and achieve success. Here are some common problems and their solutions:

Persistent Air Bubbles

If air bubbles continue to appear in the brake fluid after multiple attempts, ensure that the brake fluid reservoir remains filled to the recommended level throughout the process. Top off the reservoir as needed to prevent the introduction of additional air.

Inconsistent Brake Pedal Feel

An inconsistent or spongy brake pedal during the brake bleeding process may indicate an issue with the master cylinder. Check for leaks or damage to the master cylinder and replace it if necessary before continuing the brake bleeding process.

Brake Fluid Leaks

If you notice brake fluid leaks during the brake bleeding process, stop immediately and address the leak before continuing. Leaks can be caused by damaged brake lines, worn-out seals, or other issues that require immediate attention.

Overpressurization or Underpressurization

Overpressurization or underpressurization can occur with pressure bleeding methods, potentially damaging the brake system. Monitor the pressure closely and adjust as needed to maintain the recommended pressure levels for your specific vehicle and brake system.

Insufficient Brake Fluid

Running out of brake fluid during the brake bleeding process can introduce air into the system. Always have extra brake fluid on hand and monitor the fluid level throughout the process.

Contaminated Brake Fluid

Using contaminated brake fluid can compromise the performance and safety of your brake system. Always use fresh, clean brake fluid and dispose of used brake fluid properly according to local regulations and guidelines.

By anticipating these common issues and having practical solutions at hand, you can confidently bleed air out of brakes and maintain optimal brake performance and safety.

Post-Bleeding Maintenance: Ensuring Long-Term Brake Performance and Safety

Once you’ve successfully bled air out of your brakes, it’s essential to perform post-bleeding maintenance checks, adjustments, and follow-up procedures to ensure long-term brake performance and the safety of the vehicle and its occupants. Here’s what you should do:

Inspect the Brake System

Thoroughly inspect the entire brake system for any signs of damage, leaks, or wear. Pay close attention to brake lines, hoses, calipers, rotors, and pads. Address any issues immediately to prevent further damage or potential safety hazards.

Test Drive and Brake Function Check

After the post-bleeding maintenance checks, perform a test drive to ensure proper brake function. Gradually increase your speed during the test drive, applying the brakes firmly and smoothly at various intervals. Listen for unusual noises, feel for vibrations, and monitor the brake pedal for consistent pressure and response.

Check Fluid Levels

Regularly check the brake fluid level in the master cylinder reservoir. Top off the reservoir with fresh, clean brake fluid as needed. Maintaining the correct fluid level will help prevent air from re-entering the system and ensure optimal brake performance.

Perform Regular Brake Inspections

Schedule routine brake inspections to identify and address any potential issues before they become significant problems. A professional mechanic can perform a comprehensive brake inspection, providing valuable insights and recommendations for maintenance and repairs.

Stay Informed

Continuously educate yourself about advancements in brake system technologies and techniques. By staying informed, you can enhance your skills, make better decisions regarding brake maintenance and repairs, and contribute to the overall safety and performance of your vehicle.

Regular post-bleeding maintenance is crucial for ensuring long-term brake performance and safety. By following these guidelines, you can help extend the lifespan of your brake system and promote a safer driving experience.

Continuous Improvement: Staying Up-to-Date on Brake System Technologies and Techniques

To ensure your vehicle’s brake system remains in optimal condition, it’s essential to stay informed about advancements in brake system technologies and techniques. By continuously updating your knowledge and skills, you can enhance the safety and performance of your vehicle, as well as minimize the risks associated with outdated methods and technologies.

Follow Industry News and Trends

Stay connected with the automotive industry by following reputable news sources, blogs, and forums. These resources often cover the latest developments in brake system technologies, diagnostic tools, and repair techniques. By staying informed, you can adopt innovative approaches and cutting-edge tools to improve your brake bleeding process and overall vehicle maintenance.

Participate in Workshops and Training Sessions

Take advantage of workshops, training sessions, and educational opportunities provided by manufacturers, suppliers, and professional organizations. These events offer hands-on experience, expert guidance, and networking opportunities, allowing you to expand your knowledge, refine your skills, and learn from experienced professionals in the field.

Join Professional Organizations and Networks

Connect with other professionals and enthusiasts by joining automotive forums, social media groups, and professional organizations. Engaging in these communities allows you to share experiences, ask questions, and learn from others’ successes and challenges. Additionally, many organizations offer exclusive resources, discounts, and events for members, further supporting your continuous improvement efforts.

Invest in Quality Tools and Equipment

Equip yourself with high-quality, up-to-date tools and equipment designed for bleeding air out of brakes and maintaining your vehicle’s brake system. Modern tools often incorporate advanced features and technologies that can streamline processes, improve accuracy, and reduce the risk of errors. By investing in the right tools, you can enhance your efficiency, productivity, and overall results.

Document Your Progress

Track your continuous improvement journey by documenting your progress, noting any challenges, successes, and lessons learned along the way. Regularly reviewing your documentation can help you identify patterns, areas for improvement, and opportunities for growth. Additionally, maintaining accurate records can serve as a valuable reference for future projects and maintenance tasks.

Staying up-to-date on brake system technologies and techniques is crucial for maintaining optimal brake performance and safety. By following industry news, participating in workshops, joining professional networks, investing in quality tools, and documenting your progress, you can enhance your skills, knowledge, and overall value as a skilled automotive professional.