Why Counting Chain Links Matters: Applications and Importance

Counting chain links is an essential skill in various industries, including jewelry making, bicycle maintenance, and manufacturing. Accurate counting of chain links plays a crucial role in repairs, customization, and quality control. For instance, in jewelry making, counting chain links ensures that the right number of links are used in a design, providing consistency and precision in the final product. In bicycle maintenance, counting chain links helps determine when a chain needs replacement, ensuring optimal performance and longevity. Furthermore, in manufacturing, counting chain links is vital for inventory management, production planning, and cost estimation.

Understanding Chain Link Configurations: Identifying the Types

Chain links are versatile components with various configurations, each designed for specific applications. Recognizing the different types of chain links is essential for accurate counting and efficient workflow. Here are three primary chain link categories:

- Roller Chains: Commonly used in bicycles, motorcycles, and industrial machinery, roller chains consist of short cylindrical rollers connected by inner and outer plates. The rollers help reduce friction, enabling smooth movement and increased durability. When counting roller chains, consider the number of rollers, inner plates, and outer plates as a single link unit.

- Anchor Chains: These chains are primarily utilized in marine applications, such as anchoring boats and ships. Anchor chains typically have a robust design, with each link formed by a pair of interconnected hooks. Due to their heavy-duty nature, accurately counting anchor chains is crucial for safety and load-bearing calculations.

- Chain Mail Links: Chain mail links are commonly found in jewelry, armor, and decorative items. They are made by interlocking metal rings, creating a flexible and intricate pattern. Accurate counting of chain mail links is vital for design consistency, pattern repetition, and quality control in jewelry making and other crafts.

Understanding the distinct characteristics of these chain link types will streamline the counting process and ensure accurate results. Adapting counting techniques to the specific chain link configuration will enhance efficiency and minimize errors.

Gathering Necessary Tools and Materials: Preparing for Counting

Equipping yourself with the right tools and materials is crucial for accurate and efficient chain link counting. Here are some essential tools and how to use them effectively and safely:

- Measuring Tape: A versatile and compact tool, a measuring tape allows you to measure chain link lengths quickly and accurately. To ensure precision, pull the tape taut but avoid stretching it, which may result in inaccurate measurements. Measuring tapes with inch and metric measurements are ideal for various applications.

- Calipers: Calipers are perfect for measuring the internal and external dimensions of chain links. When using calipers, position the tool carefully around the link to obtain accurate measurements. Calipers with digital displays can provide more precise measurements than analog versions.

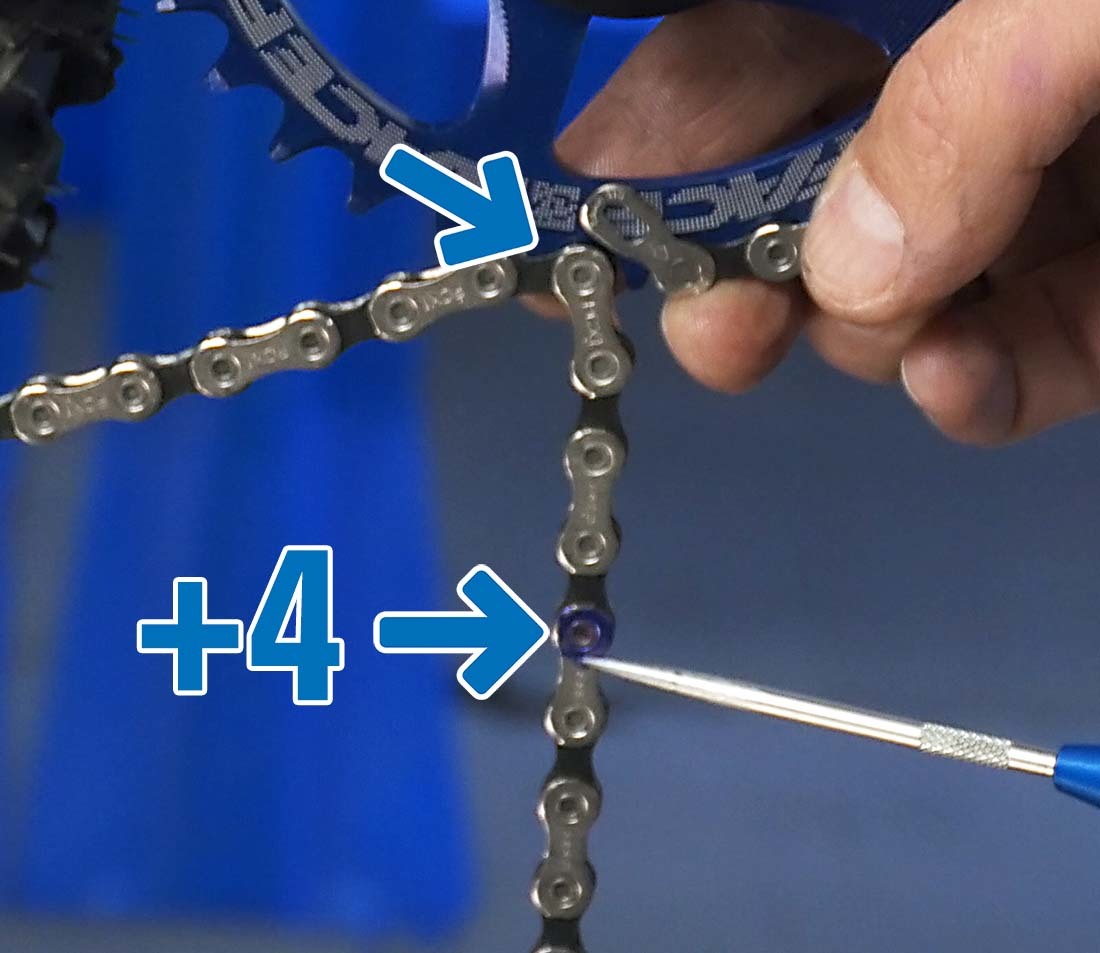

- Chain Breaker Tool: A chain breaker tool is designed to disassemble and reassemble chain links, primarily used for repairs and customization. When using a chain breaker tool, follow the manufacturer’s instructions to avoid damaging the chain or the tool. Always apply even pressure and ensure the chain is properly aligned in the tool before breaking or reconnecting links.

By familiarizing yourself with these essential tools and their proper usage, you can enhance your chain link counting accuracy and efficiency. Always prioritize safety when handling tools and materials, and consider investing in high-quality equipment for long-term use.

Manual Counting Techniques: Accurate and Efficient Methods

Manual counting of chain links can be an engaging and rewarding process when employing accurate and efficient techniques. Here are some strategies to help you master manual chain link counting:

- Counting by Pairs: Pairing chain links during the counting process can increase accuracy and reduce the likelihood of skipping or double-counting. Simply group each link with its adjacent link and count them as a pair. This method is particularly useful for uniform chain links with consistent dimensions.

- Using Visual Landmarks: Identify distinct visual landmarks along the chain, such as joins, connectors, or color variations, to simplify the counting process. By using these landmarks as reference points, you can break down the chain into smaller, more manageable sections, making counting more straightforward and less error-prone.

- Double-Checking Methods: Implementing double-checking methods can help ensure counting accuracy. For instance, count the chain links once and then reverse the direction, recounting the links to confirm the initial count. Alternatively, enlist the help of a second person to independently count the chain links, comparing results to identify any discrepancies.

By incorporating these manual counting techniques, you can improve your chain link counting accuracy and efficiency. Remember to maintain focus and patience during the counting process, as even minor distractions can lead to counting errors. With practice, you will become more adept at manual chain link counting, enhancing your skills and confidence.

Leveraging Technology: Digital Tools for Chain Link Counting

In today’s digital age, various tools and software can assist in chain link counting, increasing accuracy and efficiency. Here are some popular digital solutions and their features, benefits, and limitations:

- Smartphone Apps: Numerous smartphone apps are available for chain link counting, often featuring user-friendly interfaces and intuitive designs. These apps can automatically calculate total chain link counts, average link lengths, and even track counting progress over time. However, they may require a learning curve and may not always be as accurate as other digital tools.

- Laser Measuring Devices: Laser measuring devices offer precise distance measurements using laser technology. These tools can quickly and accurately measure chain link lengths, providing digital readouts that simplify counting. However, laser measuring devices can be expensive and may require calibration for optimal performance.

- Chain Link Counters: Specialized chain link counters are designed specifically for counting chain links, often featuring built-in digital displays and counting mechanisms. These tools can efficiently and accurately count chain links, even in large quantities. However, chain link counters may be limited to counting only specific types of chain links and can be costly.

By leveraging these digital tools, you can enhance your chain link counting accuracy and efficiency. When selecting a digital solution, consider your budget, counting requirements, and the specific features that best meet your needs. Remember to always follow the manufacturer’s instructions and safety guidelines when using digital tools and software for chain link counting.

Troubleshooting Common Issues: Overcoming Counting Challenges

Counting chain links can sometimes present unique challenges, but with the right strategies, you can maintain accuracy and efficiency. Here are some common issues and practical solutions for overcoming counting obstacles:

- Counting Linked Components: When counting chain links with additional components, such as hooks, clasps, or connectors, it’s essential to include these components in your count. To simplify the process, break down the chain into smaller sections, counting each section separately and then adding the totals together. This method can help ensure that all components are accounted for in the final count.

- Dealing with Irregular Links: Irregular chain links, such as those with varying sizes or shapes, can be challenging to count accurately. In these cases, consider using digital tools or software specifically designed for measuring and counting irregular chain links. Alternatively, you can use manual counting techniques, such as counting by pairs or using visual landmarks, to help maintain accuracy.

- Maintaining Consistency: Ensuring consistency in your counting process is crucial for accurate results. Develop a systematic approach to counting chain links, such as always starting from a specific point, counting in a consistent direction, and double-checking your work regularly. By establishing a consistent counting routine, you can minimize errors and improve overall counting efficiency.

By understanding these common issues and implementing practical solutions, you can enhance your chain link counting skills and maintain accuracy in various counting scenarios. Always be prepared to adapt your counting techniques to accommodate new challenges and maintain a high level of proficiency in chain link counting.

Practicing and Improving: Enhancing Counting Skills

Practice is essential for mastering any skill, and chain link counting is no exception. By consistently honing your counting skills, you can improve accuracy and efficiency over time. Here are some exercises and resources to help you enhance your chain link counting abilities:

- Counting Practice Chains: Obtain practice chains with various link configurations, such as roller chains, anchor chains, and chain mail links. Regularly practice counting these chains using manual techniques and digital tools to familiarize yourself with different link types and counting methods.

- Timed Counting Exercises: Set a timer and challenge yourself to count a specific number of chain links within a given timeframe. This exercise can help improve your counting speed and efficiency, allowing you to count chain links more quickly and accurately.

- Online Tutorials and Courses: Explore online resources, such as tutorials and courses, dedicated to chain link counting. These resources can provide valuable insights, tips, and techniques for improving your counting skills and staying updated on industry best practices.

By incorporating these exercises and resources into your practice routine, you can systematically enhance your chain link counting skills. Remember, consistent practice and a commitment to continuous learning are key to mastering the art of chain link counting and ensuring accurate and efficient results.

Staying Updated: Following Industry Trends and Developments

The field of chain link counting is constantly evolving, with new tools, techniques, and best practices emerging regularly. Staying informed about industry trends and advancements can help you maintain a competitive edge and ensure the highest level of accuracy and efficiency in your counting processes. Here are some ways to stay updated:

- Industry Publications: Subscribe to industry publications, newsletters, and blogs that focus on chain link counting, manufacturing, and maintenance. These resources often provide updates on the latest tools, techniques, and trends, helping you stay informed about the latest developments in the field.

- Professional Organizations: Join professional organizations related to chain link counting, such as industry associations or trade groups. These organizations often host conferences, seminars, and workshops where experts share insights, research, and best practices in chain link counting.

- Online Forums and Communities: Participate in online forums and communities dedicated to chain link counting and related fields. Engaging in discussions with fellow professionals can provide valuable insights, tips, and resources for staying updated on industry trends and advancements.

By actively seeking out and engaging with these resources, you can ensure that you remain at the forefront of chain link counting best practices and technologies. Continuous learning and adaptation are essential for staying competitive and maintaining the highest level of accuracy and efficiency in your counting processes.