The Essential Tools and Materials for Wheel Building

Successfully learning how to lace rims begins with gathering the correct tools and materials. A comprehensive toolkit ensures precision and prevents damage during the wheel building process. Essential tools include spoke wrenches, available in various sizes to match your spoke nipples. A spoke wrench that fits snugly is crucial to avoid rounding the nipple corners. Spoke holders, or pliers with a modified jaw, assist in preventing spoke twisting during tensioning, especially with bladed spokes. A truing stand greatly simplifies the process of achieving a perfectly true wheel, allowing for precise measurements of lateral and radial runout. However, truing can also be accomplished using the bike frame and brake pads as a reference. For accurate tension measurement, a spoke tension meter is invaluable. While experienced builders might rely on auditory feedback, a tension meter provides objective data, leading to a more consistent and durable wheel.

The core materials include the nipples, spokes, rim, and hub. Nipples should be of high quality, preferably brass for durability and corrosion resistance. Spokes must be the correct length, calculated precisely based on the rim’s effective rim diameter (ERD), hub flange dimensions, and chosen lacing pattern. The rim should be inspected for any defects, such as dents or cracks, before starting. Similarly, the hub flanges should be clean and free from burrs. Investing in high-quality components contributes significantly to the longevity and performance of the completed wheel. Using the correct spoke length is critical to how to lace rims properly; too short and the nipples won’t engage enough threads, too long and they’ll protrude excessively.

In addition to the above, consider a thread locking compound for the spoke threads to prevent loosening over time, particularly for wheels subjected to vibration. A lubricant applied sparingly to the spoke threads and nipple seat on the rim can aid in even tensioning. Eye protection is also recommended as a safety precaution during the tensioning process. Having these tools and materials readily available sets the stage for a smooth and successful wheel building experience and greatly increases the chances of successfully learning how to lace rims.

Understanding Spoke Patterns and Their Impact

Different spoke lacing patterns significantly influence wheel strength, stiffness, and ride quality. Understanding these patterns is crucial before learning how to lace rims. Radial lacing involves spokes extending directly from the hub to the rim, creating a visually appealing design often favored for its lightweight and aerodynamic properties. However, radial patterns are generally unsuitable for wheels subjected to high torque or braking forces, as they transmit these forces directly to the hub flange. This direct transfer can lead to stress fractures over time.

Tangential lacing, on the other hand, features spokes that cross each other, forming an angle relative to the hub. Common tangential patterns include 2-cross, 3-cross, and 4-cross. The number indicates how many spokes each spoke crosses. A 3-cross pattern is a versatile choice, balancing strength and compliance. More crosses generally increase wheel strength and durability, making them suitable for heavier riders and demanding terrains. However, they can also result in a slightly heavier and less responsive wheel. Fewer crosses create a lighter, more responsive wheel, but may compromise strength. For example, a 3-cross pattern is frequently used in mountain bikes, where durability is paramount. Learning how to lace rims with a 3-cross pattern is a good starting point.

The choice of spoke pattern also affects the wheel’s ability to absorb shocks and vibrations. Tangential patterns provide more cushioning compared to radial patterns, improving ride comfort. When considering how to lace rims, it’s important to evaluate the intended use of the wheel. A road bike wheel might benefit from a lighter, more aerodynamic design, while a mountain bike wheel requires robust construction to withstand rough trails. Selecting the appropriate spoke pattern is a critical step in building a wheel that performs optimally for its intended purpose. Correct spoke length calculation is as important as the lacing pattern chosen when considering how to lace rims.

Preparing Your Hub and Rim for Lacing

Before embarking on the process of how to lace rims, meticulous preparation of both the hub and rim is paramount. This ensures a seamless build and contributes significantly to the wheel’s overall integrity and longevity. Begin by thoroughly inspecting the hub flanges. Examine them for any imperfections such as burrs, sharp edges, or lingering grease. These flaws can impede spoke seating and compromise the structural integrity of the wheel. Use a fine file or emery cloth to gently smooth out any imperfections, ensuring a clean and even surface for the spokes to interface with. Clean the hub flanges meticulously with a degreaser to remove any dirt, oil, or grime that may have accumulated. A clean surface promotes optimal spoke seating and prevents future corrosion.

Next, turn your attention to the rim. Carefully inspect the entire rim surface, both inside and out, for any signs of damage, such as dents, cracks, or deformities. Pay particular attention to the spoke holes, ensuring they are clean and free of any obstructions. Any pre-existing damage to the rim can compromise the wheel’s structural integrity and lead to premature failure. It is critical to address any issues before proceeding with the lacing process. An often-overlooked aspect of wheel preparation is the spoke length calculation. This is perhaps the most critical step in how to lace rims. Accurate spoke length is essential for achieving proper spoke tension and ensuring a durable and reliable wheel. Use a reputable spoke length calculator, readily available online, and input the precise measurements of your hub and rim. This includes the effective rim diameter (ERD), hub flange diameter, and hub flange offset. Double-check your measurements to minimize the risk of errors. Using spokes that are either too short or too long can lead to a weak and unstable wheel.

Accurate measurements are crucial for calculating the correct spoke length to properly learn how to lace rims. Using the wrong spoke length will make it impossible to achieve proper spoke tension and build a strong, durable wheel. Consider the spoke pattern you intend to use, as this will also influence the required spoke length. Once you have confirmed the correct spoke length and addressed any imperfections in the hub and rim, you are ready to proceed with the initial spoke installation. Proper preparation is the bedrock of a successful wheel build, paving the way for a strong, true, and reliable wheel. This meticulous attention to detail ensures that the subsequent steps of how to lace rims are executed smoothly and efficiently, resulting in a high-performance wheel that will withstand the rigors of riding.

The Step-by-Step Process of Initial Spoke Installation

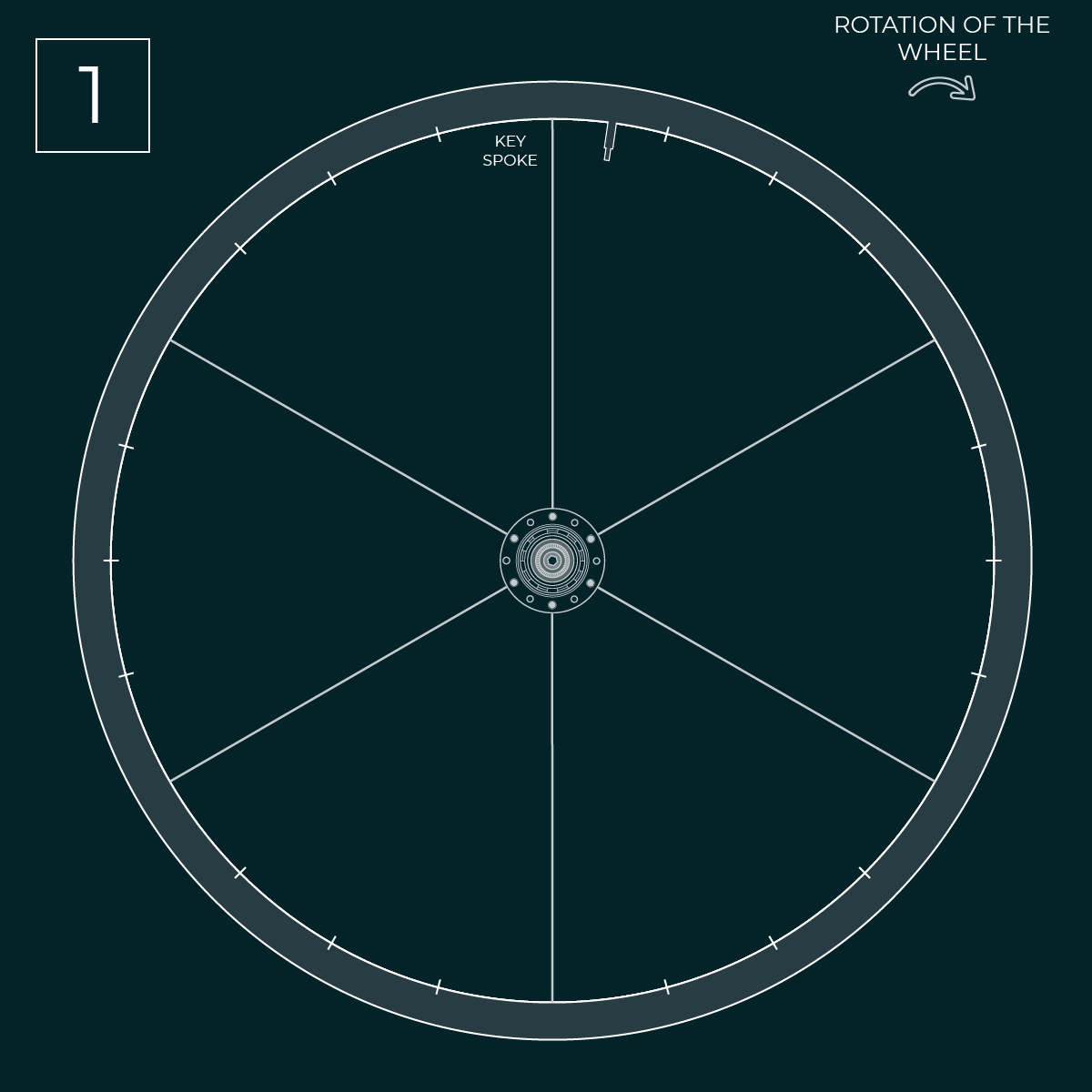

The initial spoke installation is a crucial stage in learning how to lace rims, setting the foundation for a strong and true wheel. Begin by identifying the inner and outer spokes. Inner spokes will typically have their heads positioned inside the hub flange, while outer spokes have their heads on the outside. This arrangement alternates around the hub. Take your hub and rim. Determine the starting point. This is often near the valve hole on the rim. Insert the first spoke (an inner spoke) through a hole in the hub flange. Then insert it up through the corresponding hole in the rim.

Next, thread a nipple onto the spoke, turning it a few times to secure it. Do not tighten it fully. Repeat this process with all the inner spokes on one side of the hub. Ensure each spoke goes into the correct rim hole. Maintain the alternating pattern. This step is vital for understanding how to lace rims properly. Once all inner spokes are in place on one side, flip the wheel. Then install the outer spokes on the opposite flange. These spokes will cross the inner spokes. Thread them into the corresponding rim holes and secure them with nipples, again without fully tightening.

Continue alternating sides, installing inner and outer spokes. Pay close attention to the spoke pattern you’ve chosen (radial, tangential, etc.). For a 3-cross pattern, for example, each spoke will cross three other spokes. As you lace the spokes, ensure they follow the intended pattern. Double-check that the spoke heads are correctly positioned. Also, verify that the spokes aren’t excessively bent or stressed. This careful attention to detail is key to how to lace rims effectively and create a durable wheel. The initial lacing may appear loose and uneven, but that’s normal at this stage. The next steps involve tensioning and truing the wheel. These steps are designed to bring it into perfect alignment.

Achieving Consistent Tension: The Key to a Strong Wheel

Even spoke tension is crucial for a durable and high-performing wheel. When spokes are evenly tensioned, the load is distributed uniformly across the wheel, preventing premature failure and ensuring a smooth ride. A wheel with inconsistent tension is more likely to go out of true, develop flat spots, or experience spoke breakage. Learning how to lace rims correctly and understanding tension are essential for wheel longevity.

A spoke tension meter is the most accurate tool for measuring spoke tension. This tool measures the deflection of the spoke when a specific force is applied. The reading is then compared to a chart to determine the tension in kilograms-force (kgf) or Newtons (N). Aim for the target tension recommended by the rim manufacturer. If a spoke tension meter isn’t available, experienced wheel builders can often assess tension by ear. Plucking the spokes produces a tone, and spokes with similar tension will produce similar tones. However, this method requires considerable practice and is less precise than using a tension meter. When considering how to lace rims, remember consistent tension is paramount.

Regardless of the method used, gradual tightening is key. Start by tightening all the nipples to the point where the threads are just engaged. Then, systematically tighten each spoke in small increments, working your way around the wheel. A quarter turn of the spoke wrench per spoke is a good starting point. Regularly check the tension of all spokes as you go, making adjustments as needed to maintain evenness. Over-tightening a single spoke can place undue stress on the rim and hub, leading to potential problems. This iterative process of tightening and checking is essential for achieving a strong and reliable wheel. Consistent spoke tension obtained through proper technique and tools is how to lace rims for optimal performance and durability.

Preliminary Truing and Rounding of the Wheel

The initial truing process is a critical step in learning how to lace rims, focusing on bringing the rim into a round shape and addressing any significant deviations. This stage sets the foundation for a strong and reliable wheel. If a truing stand is available, mount the wheel securely. Begin by visually inspecting the wheel for any obvious wobbles or kinks in the rim. These are known as lateral and radial runout. Lateral runout refers to side-to-side deviations, while radial runout indicates the rim is not perfectly round.

The use of a truing stand significantly simplifies this process, but it is possible to perform preliminary truing without one. A simple jig or even the bike frame itself can be used as a reference point. The key is to have a consistent and stable point against which to measure the rim’s movement. To correct lateral runout, identify the area where the rim deviates to one side. Tighten the spokes on the opposite side of the deviation, and loosen the spokes on the same side. Make small, incremental adjustments, no more than a quarter or half turn of the spoke wrench at a time. After each adjustment, spin the wheel to observe the effect. For radial runout, focus on areas where the rim dips inward or bulges outward. Tighten spokes in the areas where the rim dips inward to pull the rim outward, and loosen spokes in areas where the rim bulges outward to allow the rim to move inward. Again, small adjustments are crucial to avoid over-correcting and creating new problems. Patience is paramount during this stage. Learning how to lace rims involves understanding that it’s an iterative process.

This initial truing is about bringing the wheel into a rough approximation of its final shape. The goal is not perfection at this stage, but rather to eliminate major deviations and create a more manageable foundation for final tensioning and truing. Uneven spoke tension at this stage is normal, focus instead on the overall shape of the wheel. Remember to regularly check your progress by spinning the wheel and observing its movement relative to your reference point. Consistent observation and small, controlled adjustments are the keys to a successful preliminary truing. By carefully working through this process, the wheel builder sets the stage for a wheel that is both strong and true. Mastering how to lace rims is a skill that grows with practice, and this preliminary stage is where that learning begins.

Final Tensioning and Truing: Perfecting Your Wheel Build

The concluding stages of wheel building are crucial for achieving optimal performance and longevity. This involves fine-tuning the spoke tension, ensuring the wheel is perfectly true and round, and verifying correct dish. Achieving target spoke tension is paramount. Consult the hub and rim manufacturer’s specifications for recommended tension values. A spoke tension meter provides accurate measurements, allowing for precise adjustments. Increase tension gradually, making small, incremental turns of the spoke nipples. Aim for consistent tension across all spokes on each side of the wheel. Inconsistent tension can lead to premature wheel failure. After achieving the desired tension, focus on final truing. Lateral truing corrects side-to-side wobble. Radial truing eliminates up-and-down deviations. Use a truing stand to precisely identify and correct imperfections. Remember to make small adjustments, often less than a quarter turn of the spoke nipple. Patience is key to achieving a perfectly true wheel. Knowing how to lace rims properly contributes significantly to the final wheel trueness. Understanding how to lace rims ensures the wheel build process flows smoothly, minimizing potential issues during the final truing stages.

Dish, the centering of the rim over the hub, is another critical aspect. Use a dishing tool to check that the rim is equidistant from the locknuts on either side of the hub. Adjust spoke tension on either side of the wheel to correct any dish discrepancies. Even small dish errors can affect handling and wheel strength. Once truing and dishing are complete, perform a final stress relief. This involves applying pressure to the wheel to seat the spokes and relieve any residual stresses. Use your hands or a specialized stress-relieving tool to flex the wheel laterally. After stress relieving, re-check the trueness, roundness, and dish, making any necessary final adjustments. How to lace rims correctly from the beginning influences how well the wheel holds its shape after stress relief.

The final step is a comprehensive inspection. Ensure all spoke nipples are properly seated and that there are no loose or protruding spokes. A well-built wheel should exhibit even spoke tension, be perfectly true and round, and have correct dish. This meticulous process ensures a durable, reliable, and high-performing wheel. Mastering how to lace rims is essential for creating wheels that meet the demands of various riding conditions, and ultimately, a safe and enjoyable ride. By carefully following these steps, a wheel builder can be confident of a professional and reliable outcome.

Troubleshooting Common Wheel Building Challenges

Encountering challenges while learning how to lace rims is common, even for experienced wheel builders. Addressing these issues effectively is crucial for a successful wheel build. One frequent problem is uneven spoke tension. This can manifest as a wheel that is difficult to true or one that goes out of true easily after riding. Causes include inconsistent spoke length, variations in rim or hub manufacturing, or simply a lack of precision during the tensioning process. To resolve this, double-check spoke length calculations, and use a spoke tension meter to identify areas of high and low tension. Gradually adjust spoke nipples to equalize the tension, focusing on small increments.

Another challenge when learning how to lace rims is a warped rim. While some minor imperfections can be trued out, a severely warped rim may be beyond repair. Before beginning the build, inspect the rim for any significant bends or dents. If a warp is discovered mid-build, try to gently manipulate the rim while adjusting spoke tension to encourage it back into shape. However, avoid applying excessive force, as this could further damage the rim. Spoke wind-up is another issue that arises during tensioning. As you tighten the spoke nipples, the spoke itself can twist, leading to inaccurate tension readings. To mitigate spoke wind-up, apply a spoke lubricant to the threads and use a spoke holder to prevent the spoke from rotating while tightening the nipple. After tensioning, stress relieve the wheel by squeezing pairs of spokes together. This helps to settle the spokes and release any residual twisting forces, contributing to a more stable and durable wheel. Properly learning how to lace rims requires patience and attention to detail in addressing these challenges.

Finally, when learning how to lace rims, incorrect spoke length is a common pitfall. Too-short spokes will not engage enough threads in the nipples, leading to weak points and potential failure. Too-long spokes can protrude excessively, interfering with the tire or tube. Always double-check your spoke length calculations and measurements before cutting or ordering spokes. If you find that your spokes are slightly too long, you can sometimes add a small washer between the spoke head and the hub flange. However, this is not ideal and should only be done as a last resort. If the spokes are significantly too short, you will need to replace them with the correct size. Remember, correctly learning how to lace rims involves meticulous preparation and a willingness to troubleshoot problems as they arise. By addressing these common challenges proactively, you can increase your chances of building a strong, reliable wheel.