Determining the Right Rotor Dimensions for Optimal Performance

In the design and development of wind turbines, helicopters, drones, and other machines, accurate rotor sizing is crucial for optimal performance, safety, and efficiency. Incorrect rotor sizing can lead to reduced efficiency, increased wear, and safety risks, resulting in costly repairs, downtime, and even accidents. For instance, in wind turbines, undersized rotors can lead to reduced energy production, while oversized rotors can cause excessive vibration and stress. Similarly, in helicopters and drones, incorrect rotor sizing can affect stability, maneuverability, and overall performance. To avoid these issues, it is essential to understand how to measure rotor size accurately, taking into account the specific requirements of each application. By doing so, engineers and technicians can design and develop more efficient, reliable, and safe machines and systems.

Understanding Rotor Geometry: Key Factors to Consider

Rotor geometry plays a critical role in determining the performance of wind turbines, helicopters, drones, and other machines. The fundamental principles of rotor geometry include blade length, width, and angle, which significantly impact rotor performance. Blade length, for instance, affects the rotor’s ability to capture energy from the wind or generate lift. A longer blade can capture more energy, but it also increases the risk of blade failure. Blade width, on the other hand, influences the rotor’s efficiency and stability. A wider blade can provide more stability, but it can also increase drag and reduce efficiency. The blade angle, which is the angle between the blade and the rotor hub, also plays a crucial role in determining rotor performance. A smaller blade angle can increase energy capture, but it can also increase the risk of blade failure.

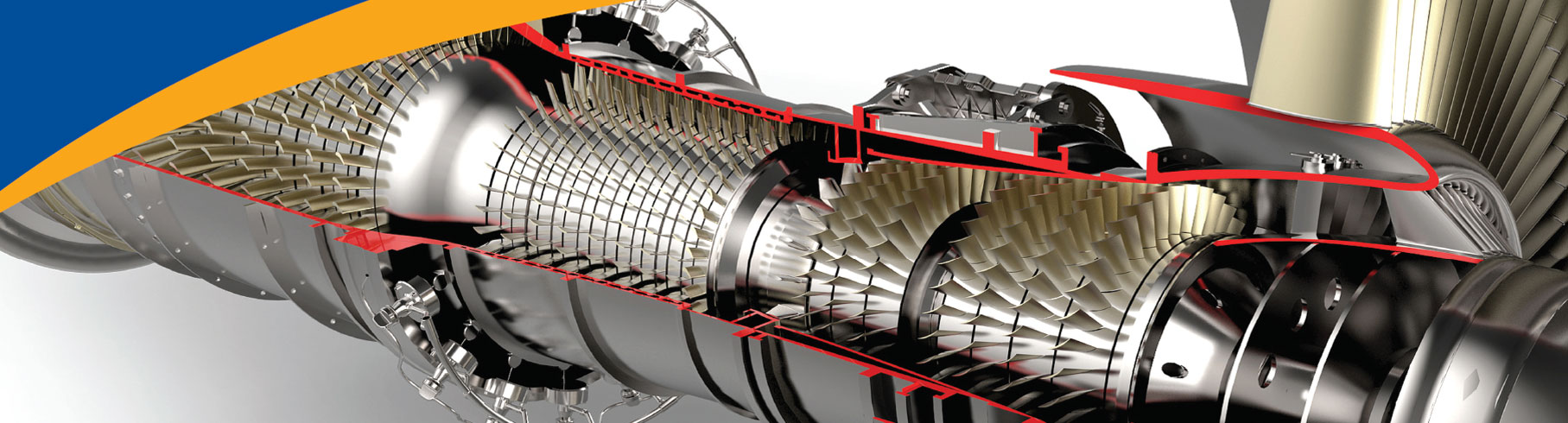

Different industries employ various rotor geometries to achieve optimal performance. In wind energy, for example, turbines often feature long, narrow blades with a small angle to maximize energy capture. In aerospace, helicopter rotors typically have shorter, wider blades with a larger angle to provide stability and maneuverability. In robotics, drone rotors often feature short, narrow blades with a small angle to minimize weight and maximize agility. Understanding the key factors of rotor geometry is essential to designing and developing efficient, reliable, and safe machines and systems. By considering these factors, engineers and technicians can optimize rotor performance and achieve their desired outcomes.

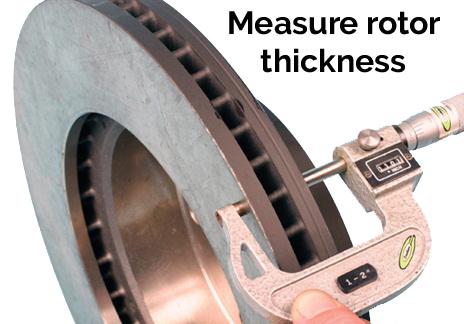

Measuring Rotor Size: Tools and Techniques

Accurate measurement of rotor size is crucial in ensuring optimal performance, safety, and efficiency in various applications. To achieve this, engineers and technicians employ various tools and techniques to measure rotor size. Calipers, micrometers, and laser scanners are some of the common tools used to measure rotor size. Calipers, for instance, are ideal for measuring blade length and width, while micrometers are better suited for measuring small dimensions such as blade thickness. Laser scanners, on the other hand, provide high-accuracy measurements of complex rotor geometries.

When choosing a tool for measuring rotor size, it is essential to consider the specific requirements of the application. For example, in wind energy, where rotor blades are typically long and narrow, calipers or laser scanners may be more suitable. In aerospace, where rotor blades are shorter and wider, micrometers may be more appropriate. Additionally, it is crucial to ensure that the tool is properly calibrated and maintained to ensure accurate measurements.

When measuring rotor size, it is also important to follow proper measurement techniques. This includes ensuring that the tool is properly aligned with the rotor blade, taking multiple measurements to account for any variations, and using reference points to ensure accuracy. By following these guidelines and using the right tools, engineers and technicians can ensure accurate measurements of rotor size, which is critical in achieving optimal performance, safety, and efficiency.

Learning how to measure rotor size accurately is a critical skill for engineers and technicians working in various industries. By mastering the tools and techniques outlined above, professionals can ensure that their rotors are properly sized, leading to improved performance, reduced wear, and enhanced safety. Whether in wind energy, aerospace, or robotics, accurate measurement of rotor size is essential in achieving optimal results.

Calculating Rotor Size: Formulas and Equations

Calculating rotor size involves the application of mathematical formulas and equations to determine the optimal dimensions of the rotor blades. These calculations are critical in ensuring that the rotor operates efficiently, safely, and within the desired performance parameters. In this section, we will present the key formulas and equations used to calculate rotor size, including the calculation of blade length, width, and angle.

One of the most common formulas used to calculate rotor size is the blade element momentum (BEM) theory. This theory is based on the assumption that the rotor blades can be divided into small elements, each of which produces a force perpendicular to the blade surface. The BEM theory can be used to calculate the optimal blade length, width, and angle for a given rotor application.

Another important formula used in rotor size calculation is the tip-speed ratio (TSR) equation. This equation relates the rotor tip speed to the wind speed, and is used to determine the optimal rotor size for wind energy applications. The TSR equation is given by: TSR = (Rotor Tip Speed) / (Wind Speed), where the rotor tip speed is the speed at which the rotor tips rotate, and the wind speed is the speed of the wind.

In addition to these formulas, engineers and technicians also use various equations to calculate rotor size, including the calculation of blade twist, camber, and taper. These equations take into account the aerodynamic and structural properties of the rotor blades, and are used to optimize the rotor design for specific applications.

By applying these formulas and equations, engineers and technicians can accurately calculate rotor size, ensuring that the rotor operates within the desired performance parameters. This is critical in achieving optimal performance, safety, and efficiency in various applications, including wind energy, aerospace, and robotics. By mastering the art of calculating rotor size, professionals can unlock the full potential of their rotors, leading to improved performance, reduced wear, and enhanced safety.

Common Mistakes to Avoid When Measuring Rotor Size

Measuring rotor size is a critical task that requires attention to detail and a thorough understanding of the measurement process. However, even with the best intentions, mistakes can occur, leading to inaccurate measurements and suboptimal rotor performance. In this section, we will identify common errors and pitfalls to avoid when measuring rotor size, and provide advice on how to minimize errors and ensure accurate results.

One of the most common mistakes to avoid is incorrect tool selection. Using a tool that is not suitable for the job can lead to inaccurate measurements and damage to the rotor. For example, using a caliper to measure the width of a rotor blade may not provide accurate results, especially if the blade is curved or tapered. In such cases, a laser scanner or a specialized rotor measurement tool may be more appropriate.

Inadequate measurement techniques are another common pitfall to avoid. This includes failing to take multiple measurements, not using reference points, and not accounting for variations in the rotor geometry. To avoid these mistakes, it is essential to develop a measurement plan that takes into account the specific requirements of the rotor and the measurement tool being used.

Miscalculations are also a common mistake to avoid when measuring rotor size. This includes errors in calculating the blade length, width, and angle, as well as mistakes in applying the formulas and equations used to calculate rotor size. To avoid miscalculations, it is essential to double-check calculations and use software or calculators specifically designed for rotor size calculation.

By being aware of these common mistakes and taking steps to avoid them, engineers and technicians can ensure accurate measurements of rotor size, leading to optimal performance, safety, and efficiency in various applications. Remember, accurate measurement of rotor size is critical in achieving the desired results, and mistakes can have serious consequences. By following best practices and avoiding common mistakes, professionals can ensure that their rotors are properly sized and optimized for peak performance.

Real-World Applications: Measuring Rotor Size in Practice

In various industries, measuring rotor size is a critical task that requires precision and accuracy. In this section, we will explore real-world applications of measuring rotor size, highlighting the challenges and solutions encountered in these industries.

In the wind energy industry, measuring rotor size is crucial for optimizing wind turbine performance. For example, a wind turbine manufacturer may use laser scanners to measure the rotor blades, ensuring that they are accurately sized and aligned for maximum energy production. By measuring rotor size accurately, wind turbine manufacturers can improve efficiency, reduce wear, and increase energy output.

In the aerospace industry, measuring rotor size is critical for ensuring the safety and performance of helicopters and drones. For instance, a helicopter manufacturer may use calipers and micrometers to measure the rotor blades, ensuring that they meet strict safety and performance standards. By measuring rotor size accurately, aerospace manufacturers can improve safety, reduce maintenance costs, and enhance overall performance.

In the robotics industry, measuring rotor size is essential for optimizing the performance of robotic arms and grippers. For example, a robotics manufacturer may use 3D scanning technology to measure the rotor size of a robotic arm, ensuring that it can accurately grasp and manipulate objects. By measuring rotor size accurately, robotics manufacturers can improve precision, reduce errors, and enhance overall performance.

In each of these industries, measuring rotor size is a critical task that requires precision, accuracy, and attention to detail. By understanding the challenges and solutions encountered in these industries, professionals can develop effective strategies for measuring rotor size, leading to improved performance, safety, and efficiency.

By learning how to measure rotor size in practice, professionals can apply these skills to their own projects and applications, ensuring that their rotors are properly sized and optimized for peak performance. Whether in wind energy, aerospace, or robotics, accurate measurement of rotor size is critical for achieving success.

Best Practices for Rotor Size Measurement and Verification

To ensure accurate and reliable rotor size measurements, it is essential to follow best practices for measurement and verification. In this section, we will outline the key principles and guidelines for implementing effective measurement and verification procedures.

Calibration is a critical step in the measurement process. Regular calibration of measurement tools and equipment ensures that they are accurate and reliable, reducing the risk of errors and inaccuracies. It is recommended to calibrate measurement tools at least once a year, or as specified by the manufacturer.

Regular maintenance is another essential aspect of rotor size measurement and verification. This includes cleaning and inspecting measurement tools, as well as performing routine checks on equipment and software. By maintaining equipment and software, professionals can ensure that they are functioning correctly and providing accurate results.

Quality control is a crucial aspect of rotor size measurement and verification. This involves implementing procedures to ensure that measurements are accurate, reliable, and consistent. Quality control measures may include checks on measurement data, verification of results, and implementation of corrective actions in case of errors or inaccuracies.

In addition to these best practices, it is essential to follow established standards and guidelines for rotor size measurement and verification. This includes adhering to industry-specific standards, such as those set by the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO).

By following these best practices, professionals can ensure that their rotor size measurements are accurate, reliable, and consistent. This, in turn, can lead to improved performance, safety, and efficiency in various applications, including wind energy, aerospace, and robotics. By understanding how to measure rotor size accurately and reliably, professionals can optimize their rotors for peak performance and achieve their desired outcomes.

Conclusion: The Importance of Accurate Rotor Sizing

In conclusion, accurate rotor sizing is a critical aspect of ensuring optimal performance, safety, and efficiency in various applications, including wind energy, aerospace, and robotics. By understanding how to measure rotor size accurately and reliably, professionals can optimize their rotors for peak performance and achieve their desired outcomes.

Throughout this article, we have explored the importance of accurate rotor sizing, the fundamental principles of rotor geometry, and the various methods and tools used to measure rotor size. We have also discussed the mathematical formulas and equations used to calculate rotor size, common mistakes to avoid, and real-world applications of measuring rotor size.

By following the best practices outlined in this article, professionals can ensure that their rotor size measurements are accurate, reliable, and consistent. This, in turn, can lead to improved performance, safety, and efficiency in various applications. Whether you are working in wind energy, aerospace, or robotics, understanding how to measure rotor size accurately is crucial for achieving success.

In summary, accurate rotor sizing is essential for optimal performance, safety, and efficiency. By mastering the techniques and principles outlined in this article, professionals can ensure that their rotors are properly sized and optimized for peak performance. Remember, how to measure rotor size accurately is a critical skill that can make all the difference in achieving success in your projects and applications.