The Anatomy of a Box: Understanding the Components

When it comes to putting together a box, understanding the different parts is crucial for a successful assembly. A typical box consists of several components, including the top and bottom flaps, sides, and any additional features such as handles or inserts. Knowing how to identify and work with each of these components is essential for building a sturdy and functional box. By familiarizing yourself with the anatomy of a box, you’ll be better equipped to tackle the assembly process with confidence. Whether you’re a seasoned pro or a beginner, taking the time to understand the components of a box will pay off in the long run, ensuring that your box is assembled correctly and efficiently. So, before you start assembling, take a closer look at the different parts of your box and get ready to learn how to put together a box like a pro.

Preparing the Workspace: Essential Tools and Materials

Before diving into the assembly process, it’s crucial to prepare a suitable workspace with the necessary tools and materials. A flat, stable surface is essential for assembling a box, as it provides a solid foundation for building a sturdy structure. Additionally, having the right tools and materials within reach can save time and reduce frustration. The most common tools required for box assembly include tape, scissors, and a ruler or straightedge. Depending on the type of box being assembled, other specific items may be needed, such as glue, staples, or specialized fasteners. Having a well-organized workspace with all the necessary tools and materials at hand will help ensure a smooth and efficient assembly process, ultimately leading to a well-constructed box that is ready for use. By taking the time to prepare your workspace, you’ll be well on your way to learning how to put together a box like a pro.

Unpacking and Organizing the Box Components

Once the necessary tools and materials are in place, it’s time to unpack and organize the box components. This crucial step sets the stage for a smooth assembly process, ensuring that all parts are accounted for and easily accessible. When unpacking the box components, take care to identify and separate the different parts, including the top and bottom flaps, sides, and any additional features such as handles or inserts. A well-organized workspace will help prevent mistakes and reduce the risk of missing or damaged components. To ensure a successful assembly, take the time to carefully examine each component, checking for any damage or defects. By doing so, you’ll be able to identify any potential issues early on and make necessary adjustments before proceeding with the assembly process. By following these simple steps, you’ll be well on your way to learning how to put together a box efficiently and effectively.

Assembling the Box: A Step-by-Step Process

With the workspace prepared and the box components organized, it’s time to begin the assembly process. To ensure a successful assembly, follow these step-by-step instructions:

Step 1: Attach the Sides – Start by attaching the sides of the box to the bottom flap, using the appropriate adhesive or fastening method. Make sure the sides are aligned properly and securely attached to prevent the box from collapsing.

Step 2: Attach the Top Flap – Next, attach the top flap to the sides of the box, ensuring a secure and even seal. Apply gentle pressure to ensure the flap is properly aligned and attached.

Step 3: Add Additional Features – If the box includes additional features such as handles or inserts, attach them according to the manufacturer’s instructions. Make sure these features are securely attached to prevent damage or detachment during use.

By following these steps, you’ll be able to successfully assemble the box and ensure it’s ready for use. Remember to take your time and work carefully to avoid mistakes and ensure a sturdy and secure box. By mastering the art of box assembly, you’ll be able to efficiently and effectively learn how to put together a box that meets your needs.

Tips and Tricks for a Secure and Sturdy Box

To ensure a secure and sturdy box, it’s essential to follow some additional tips and tricks. By incorporating these techniques into your assembly process, you’ll be able to create a box that’s strong, durable, and ready for use.

Apply Even Pressure – When attaching the sides, top, and bottom flaps, apply even pressure to ensure a secure seal. This will help prevent weak points and ensure the box can withstand the weight and stress of its contents.

Choose the Right Tape – Select a high-quality tape that’s specifically designed for box assembly. This will provide a strong and durable bond, ensuring the box remains secure during use.

Reinforce Weak Points – Identify potential weak points in the box, such as the corners or seams, and reinforce them with additional tape or support. This will help prevent damage and ensure the box remains sturdy.

By following these tips and tricks, you’ll be able to create a box that’s secure, sturdy, and ready for use. Remember, learning how to put together a box is a skill that requires patience, attention to detail, and practice. With these techniques, you’ll be well on your way to mastering the art of box assembly.

Common Mistakes to Avoid When Assembling a Box

When assembling a box, it’s essential to avoid common mistakes that can compromise the structural integrity and functionality of the box. By being aware of these mistakes, you can take steps to prevent them and ensure a successful assembly.

Incorrect Folding – One of the most common mistakes is incorrect folding of the flaps or sides. This can lead to a weak or unstable box that’s prone to collapse. To avoid this, make sure to follow the manufacturer’s instructions and take your time when folding the components.

Insufficient Tape – Using insufficient tape or applying it incorrectly can lead to a box that’s not secure or sturdy. Make sure to use the correct type of tape and apply it evenly to ensure a strong bond.

Poor Alignment – Poor alignment of the sides, top, and bottom flaps can result in a box that’s not square or stable. To avoid this, take your time when assembling the box and ensure that all components are properly aligned.

By being aware of these common mistakes, you can take steps to avoid them and ensure a successful assembly. Remember, learning how to put together a box requires patience, attention to detail, and practice. With these tips, you’ll be well on your way to mastering the art of box assembly and creating a box that’s strong, durable, and ready for use.

Special Considerations for Large or Unusual Boxes

When assembling large or unusual boxes, there are special considerations to keep in mind to ensure a successful assembly. These types of boxes often require additional support, specialized tools, and creative problem-solving to overcome unique challenges.

Handling Oversized Components – Large boxes often come with oversized components that can be difficult to handle and maneuver. To overcome this, use a team of people to assist with assembly, or consider using specialized tools such as pulleys or levers to make the process easier.

Reinforcing Weak Points – Large or unusual boxes often have weak points that need to be reinforced to ensure structural integrity. Use additional tape, staples, or other fastening methods to reinforce these areas and prevent collapse.

Adapting to Unique Features – Unusual boxes often come with unique features such as irregular shapes, cutouts, or custom inserts. To adapt to these features, take your time to study the box’s design and plan your assembly strategy accordingly. Consider using specialized tools or materials to accommodate these unique features.

By considering these special considerations, you’ll be able to successfully assemble large or unusual boxes and ensure they’re ready for use. Remember, learning how to put together a box requires patience, attention to detail, and practice. With these tips, you’ll be well on your way to mastering the art of box assembly and creating boxes that are strong, durable, and functional.

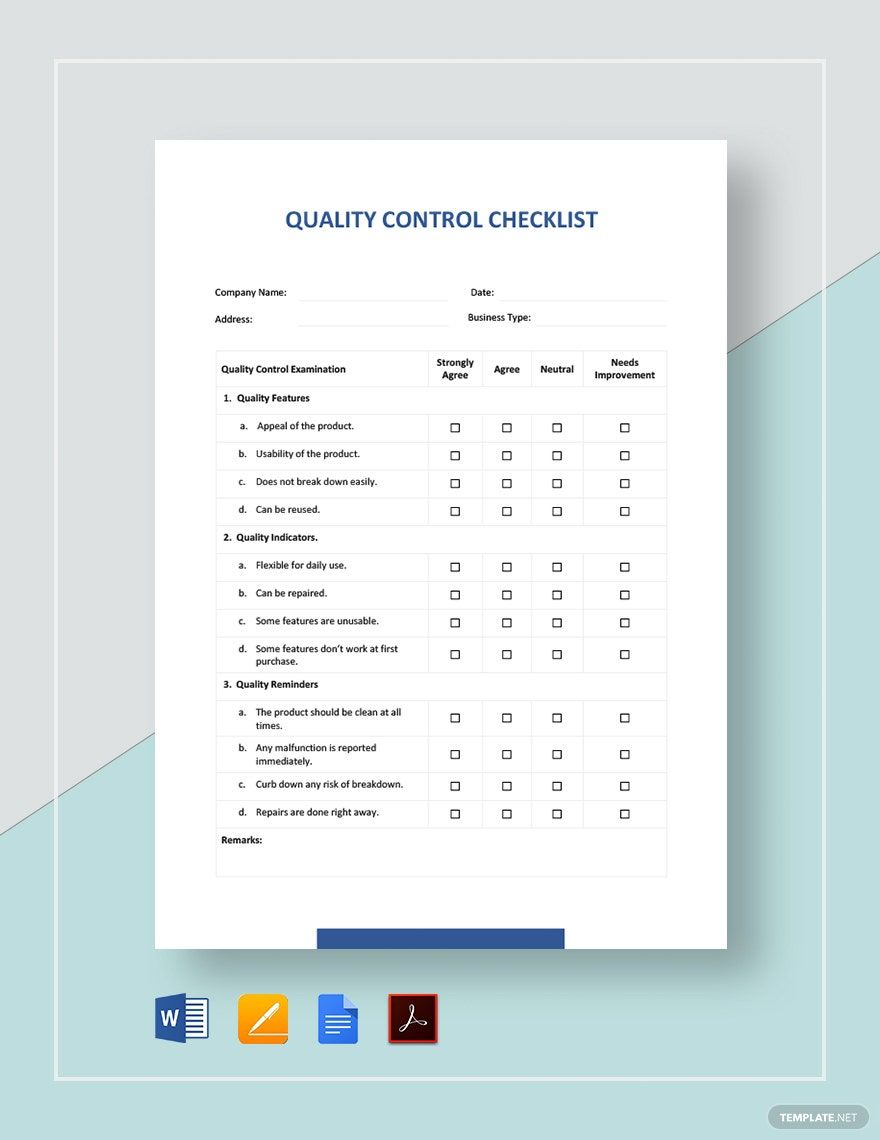

Final Check and Quality Control

Once the box is assembled, it’s essential to conduct a final check and quality control to ensure it’s properly assembled and ready for use. This step is crucial in identifying any mistakes or weaknesses that may have occurred during the assembly process.

Checklist of Key Components – Verify that all components are properly attached, including the sides, top and bottom flaps, and any additional features such as handles or inserts. Ensure that all flaps are securely closed and that the box is square and stable.

Inspect the Box for Damage – Inspect the box for any signs of damage, such as tears, creases, or worn-out areas. If any damage is found, consider replacing the box or repairing it before use.

Test the Box’s Structural Integrity – Gently test the box’s structural integrity by applying gentle pressure to the sides and top. This will help identify any weak points that may need to be reinforced.

By conducting a thorough final check and quality control, you can ensure that your box is properly assembled and ready for use. Remember, learning how to put together a box requires attention to detail and a commitment to quality. With these tips, you’ll be able to create boxes that are strong, durable, and functional, and master the art of box assembly.