Recognizing the Signs of Air in Your Brake System

Air in the brake system can be a serious issue that compromises safety on the road. To determine if your brakes need bleeding, it’s essential to recognize the common symptoms of air in the brake system. These symptoms can include spongy brake pedals, increased stopping distances, and unusual noises.

A spongy brake pedal is often the first sign of air in the brake system. When air is present, the brake pedal may feel soft or squishy, making it difficult to achieve the desired level of braking performance. This can be particularly hazardous, especially in emergency situations where quick and decisive braking is necessary.

In addition to spongy brake pedals, air in the brake system can also cause increased stopping distances. When air is present, the brake fluid may not be able to flow properly, leading to a delay in the braking process. This can result in longer stopping distances, which can increase the risk of accidents.

Unusual noises are another common symptom of air in the brake system. When air is present, it can cause the brake system to produce strange sounds, such as hissing, grinding, or squealing. These noises can be a clear indication that something is amiss with the brake system.

By recognizing these symptoms, drivers can take prompt action to address the issue and ensure their safety on the road. If you’re experiencing any of these symptoms, it’s crucial to have your brakes inspected and bled as soon as possible. In this article, we’ll provide a step-by-step guide on how to diagnose and fix brake issues related to air in the system.

Understanding the Role of Brake Fluid in Your Vehicle

Brake fluid plays a crucial role in maintaining a healthy brake system. It is a hydraulic fluid that transmits pressure from the brake pedal to the brake calipers, allowing the vehicle to slow down or come to a stop. Brake fluid is also responsible for lubricating the moving parts of the brake system, preventing corrosion and wear.

There are several types of brake fluid available, each with its own unique characteristics and properties. The most common types of brake fluid are DOT 3, DOT 4, and DOT 5.1. DOT 3 is the most widely used brake fluid, while DOT 4 is a high-performance brake fluid used in high-performance vehicles. DOT 5.1 is a synthetic brake fluid used in vehicles that require a high level of brake fluid performance.

Over time, brake fluid can become contaminated with moisture, dirt, and other debris. This can cause the brake fluid to break down, leading to a decrease in its performance and effectiveness. Contaminated brake fluid can also cause corrosion and wear on the brake system’s moving parts, leading to premature wear and tear.

It is essential to check the brake fluid level regularly and top it off as needed. It is also recommended to change the brake fluid every 30,000 to 50,000 miles, depending on the vehicle manufacturer’s recommendations. By maintaining the brake fluid, drivers can help ensure the optimal performance and safety of their vehicle’s brake system.

In addition to regular maintenance, it is also important to use the correct type of brake fluid for your vehicle. Using the wrong type of brake fluid can cause damage to the brake system and compromise its performance. By understanding the role of brake fluid in your vehicle and taking steps to maintain it, drivers can help ensure their safety on the road.

How to Check for Air in Your Brake Lines

Inspecting brake lines for signs of air is a crucial step in diagnosing brake problems. Air in the brake system can cause spongy brake pedals, increased stopping distances, and unusual noises. To check for air in your brake lines, follow these steps:

Step 1: Gather the necessary tools and equipment. You will need a brake line inspection kit, which typically includes a brake line tester and a set of adapters. You will also need a pair of safety glasses and a pair of gloves to protect yourself from any potential hazards.

Step 2: Locate the brake lines. The brake lines are typically located near the brake calipers and the master cylinder. Make sure to consult your vehicle’s repair manual for specific locations and instructions.

Step 3: Inspect the brake lines for signs of air. Use the brake line tester to pressurize the brake system and check for any leaks or bubbles. Look for any signs of corrosion, rust, or damage to the brake lines.

Step 4: Check the brake fluid level. Make sure the brake fluid level is at the recommended level. If the level is low, top it off with the recommended type of brake fluid.

Step 5: Bleed the brake system. If you find any air in the brake system, you will need to bleed the system to remove the air. Use a brake bleeding kit and follow the manufacturer’s instructions.

Precautions to take when working with brake systems:

Always wear safety glasses and gloves when working with brake systems.

Make sure the vehicle is on a level surface and apply the parking brake.

Never mix different types of brake fluid.

Always follow the manufacturer’s instructions for brake bleeding and maintenance.

By following these steps and taking the necessary precautions, you can help ensure the optimal performance and safety of your vehicle’s brake system.

Identifying the Causes of Air in Your Brake System

Air in the brake system can be caused by a variety of factors, including worn-out brake pads, faulty master cylinders, or improper brake bleeding techniques. To diagnose these issues, it’s essential to understand the common causes of air entering the brake system.

Worn-out brake pads are a common cause of air in the brake system. When brake pads wear down, they can create a gap between the pad and the rotor, allowing air to enter the system. To diagnose worn-out brake pads, look for signs of wear on the pads, such as scoring or excessive wear on the rotor.

Faulty master cylinders can also cause air to enter the brake system. The master cylinder is responsible for converting non-hydraulic pressure from the brake pedal into hydraulic pressure that is transmitted to the brake calipers. If the master cylinder is faulty, it can cause air to enter the system. To diagnose a faulty master cylinder, look for signs of leakage or corrosion on the cylinder.

Improper brake bleeding techniques can also cause air to enter the brake system. Brake bleeding is the process of removing air from the brake system, and if it’s not done correctly, it can cause air to enter the system. To diagnose improper brake bleeding techniques, look for signs of air in the brake lines or calipers.

Other causes of air in the brake system include clogged brake lines, faulty brake calipers, or contaminated brake fluid. To diagnose these issues, it’s essential to perform a thorough inspection of the brake system and look for signs of air or contamination.

By understanding the common causes of air in the brake system, you can take steps to prevent these issues and ensure the optimal performance and safety of your vehicle’s brake system.

The Risks of Neglecting Brake Maintenance

Neglecting brake maintenance can have serious consequences, including reduced stopping power, increased risk of accidents, and costly repairs. When brake maintenance is neglected, the brake system can become compromised, leading to a range of problems that can put drivers and passengers at risk.

One of the most significant risks of neglecting brake maintenance is reduced stopping power. When brake pads wear down or brake fluid becomes contaminated, the brake system can lose its ability to stop the vehicle effectively. This can lead to increased stopping distances, which can increase the risk of accidents.

Increased risk of accidents is another significant risk of neglecting brake maintenance. When the brake system is compromised, drivers may not be able to stop their vehicle in time to avoid a collision. This can lead to serious injuries or even fatalities.

Costly repairs are another consequence of neglecting brake maintenance. When brake problems are left unchecked, they can lead to more extensive and expensive repairs down the line. For example, if brake pads are not replaced regularly, they can wear down to the point where they damage the brake rotors, leading to costly repairs.

Regular brake maintenance is essential to preventing these risks. By staying on top of brake maintenance, drivers can help ensure their safety on the road and avoid costly repairs. This includes regular brake fluid checks, pad replacements, and system inspections.

It’s also important to note that neglecting brake maintenance can lead to more severe problems, such as brake failure. Brake failure can occur when the brake system is compromised to the point where it can no longer function properly. This can lead to serious accidents and injuries.

By understanding the risks of neglecting brake maintenance, drivers can take steps to prevent these problems and ensure their safety on the road.

How to Bleed Your Brakes: A Beginner’s Guide

Bleeding your brakes is an essential maintenance task that helps to remove air from the brake system, ensuring optimal braking performance and safety on the road. In this guide, we will walk you through the steps to bleed your brakes, including the tools needed, the process, and safety precautions.

Tools Needed:

Brake bleeding kit

Brake fluid

Wheel chocks

Jack and jack stands

Socket wrench or ratchet and socket

Process:

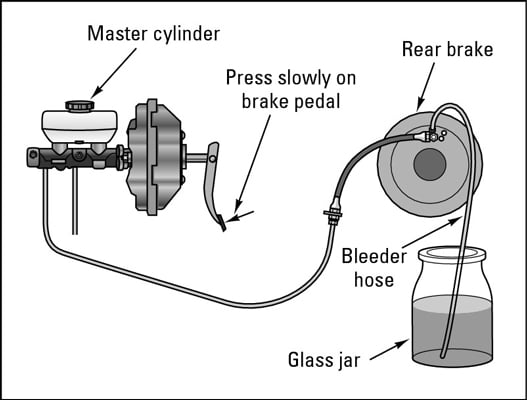

Step 1: Jack up the vehicle and remove the wheels. This will give you access to the brake calipers and brake lines.

Step 2: Locate the brake bleeding valve on the brake caliper. This valve is usually located on the top of the caliper and has a small nipple on the end.

Step 3: Attach the brake bleeding kit to the valve and pump the brake fluid through the system. This will help to remove any air that may be present in the system.

Step 4: Continue to pump the brake fluid through the system until you see a steady stream of fluid coming out of the valve. This indicates that the system is fully bled.

Safety Precautions:

Always wear protective gloves and safety glasses when working with brake systems.

Make sure the vehicle is securely supported by jack stands and wheel chocks before starting the bleeding process.

Never mix different types of brake fluid, as this can cause damage to the brake system.

Differences between Manual and Power Bleeding Methods:

Manual bleeding involves using a brake bleeding kit and pumping the brake fluid through the system by hand. This method is more time-consuming and requires more effort, but it is also more cost-effective.

Power bleeding involves using a power bleeding machine to pump the brake fluid through the system. This method is faster and more efficient, but it also requires a significant investment in equipment.

By following these steps and taking the necessary safety precautions, you can ensure that your brakes are properly bled and functioning optimally.

Troubleshooting Common Brake Bleeding Issues

Brake bleeding can be a complex process, and issues can arise during the process. In this section, we will discuss common brake bleeding issues and provide tips and solutions to overcome these challenges.

Air Pockets:

Air pockets can form in the brake lines or calipers during the bleeding process, causing the brake fluid to become trapped and unable to flow properly. To overcome this issue, try using a brake bleeding kit with a built-in air pocket removal tool. This tool can help to remove air pockets and ensure that the brake fluid flows properly.

Clogged Brake Lines:

Clogged brake lines can prevent brake fluid from flowing properly, causing the brake system to malfunction. To overcome this issue, try using a brake line cleaning kit to clean out any debris or blockages in the brake lines.

Faulty Bleeding Equipment:

Faulty bleeding equipment can cause brake fluid to leak or become contaminated, leading to brake system malfunctions. To overcome this issue, try using high-quality bleeding equipment and following the manufacturer’s instructions for use.

Other Common Issues:

Other common issues that can arise during brake bleeding include brake fluid leaks, clogged brake calipers, and faulty master cylinders. To overcome these issues, try using a brake system diagnostic tool to identify the problem and following the manufacturer’s instructions for repair.

Preventing Brake Bleeding Issues:

To prevent brake bleeding issues, it’s essential to follow proper brake bleeding techniques and use high-quality bleeding equipment. Regular brake maintenance, including brake fluid checks and pad replacements, can also help to prevent brake system malfunctions.

By following these tips and solutions, you can overcome common brake bleeding issues and ensure that your brake system is functioning properly.

Maintenance Tips to Prevent Future Brake Problems

Regular brake maintenance is essential to preventing future brake problems and ensuring the safety of your vehicle. Here are some maintenance tips to help you stay on top of brake maintenance:

Regular Brake Fluid Checks:

Brake fluid is a critical component of your vehicle’s brake system. It helps to transmit pressure from the brake pedal to the brake calipers, allowing your vehicle to stop safely. Regular brake fluid checks can help to identify any potential issues before they become major problems.

Pad Replacements:

Brake pads are a wear item that needs to be replaced regularly. Worn-out brake pads can cause your vehicle to pull to one side or vibrate when you apply the brakes. Regular pad replacements can help to prevent these issues and ensure your vehicle stops safely.

System Inspections:

Regular system inspections can help to identify any potential issues with your vehicle’s brake system. This includes checking the brake lines, calipers, and master cylinder for any signs of wear or damage.

Importance of Staying on Top of Brake Maintenance:

Staying on top of brake maintenance is essential to ensuring the safety of your vehicle. Neglecting brake maintenance can lead to reduced stopping power, increased risk of accidents, and costly repairs. By following these maintenance tips, you can help to prevent future brake problems and ensure your vehicle stops safely.

Additional Tips:

In addition to regular brake fluid checks, pad replacements, and system inspections, there are several other things you can do to help prevent future brake problems. These include:

Driving safely and avoiding sudden stops

Avoiding driving in extreme temperatures

Not carrying excessive loads

Not towing trailers or boats

By following these tips and staying on top of brake maintenance, you can help to ensure your vehicle’s brake system is functioning properly and safely.