Recognizing the Signs of Air in Your Brake System

When it comes to brake maintenance, one of the most critical aspects to monitor is the presence of air in the brake system. Air can enter the system through various means, including worn-out brake lines, faulty master cylinders, or contaminated brake fluid. If left unchecked, air in the brake system can lead to a range of problems, from spongy brake pedals to increased stopping distances. But how do you know if your brakes need bleeding?

One of the most common symptoms of air in the brake system is a spongy brake pedal. When you press the brake pedal, it should feel firm and responsive. However, if the pedal feels soft or squishy, it may be a sign that air has entered the system. Another indication of air in the brake system is a longer stopping distance. If you notice that your vehicle is taking longer to stop than usual, it could be a sign that the brakes are not functioning properly.

Unusual noises when applying the brakes can also be a sign of air in the brake system. If you hear a hissing or grinding sound when you press the brake pedal, it may indicate that air is present in the system. In some cases, air in the brake system can also cause the brake warning light to illuminate on the dashboard.

It’s essential to address air in the brake system promptly to ensure safe and reliable braking performance. If you suspect that your brakes need bleeding, it’s crucial to consult a professional mechanic or brake specialist. They can assess the brake system and perform the necessary repairs to ensure your vehicle is safe to drive.

In some cases, air in the brake system can be caused by low brake fluid levels or contaminated brake fluid. If the brake fluid level is low, it can cause the brake system to draw in air, leading to a range of problems. Similarly, contaminated brake fluid can also cause air to enter the system. Regular brake fluid checks and maintenance can help prevent air from entering the brake system.

By recognizing the signs of air in the brake system, you can take proactive steps to address the issue and ensure your vehicle’s brakes are functioning properly. Remember, brake safety is crucial, and neglecting to address air in the brake system can have serious consequences. If you’re unsure about how to tell if your brakes need bleeding, consult a professional mechanic or brake specialist for guidance.

Understanding the Importance of Proper Brake Fluid Levels

Brake fluid plays a crucial role in the brake system, transmitting pressure from the master cylinder to the brake calipers, which then apply the brakes. However, low brake fluid levels or contaminated fluid can lead to air entering the system, causing a range of problems, including spongy brake pedals and increased stopping distances. To prevent air from entering the brake system, it’s essential to maintain proper brake fluid levels.

Checking brake fluid levels is a relatively simple process that can be done at home with a few basic tools. The first step is to locate the brake fluid reservoir, which is usually a clear plastic container with a cap on top. Next, remove the cap and dip a brake fluid test strip into the reservoir. The test strip will indicate the current brake fluid level and condition. If the level is low, top it off with the recommended type of brake fluid.

It’s also important to check the brake fluid condition, as contaminated fluid can cause air to enter the system. Look for signs of contamination, such as dark or murky fluid, and replace it if necessary. It’s recommended to change the brake fluid every 30,000 to 50,000 miles, depending on the vehicle manufacturer’s recommendations.

In addition to checking brake fluid levels, it’s also essential to inspect the brake fluid reservoir and lines for signs of damage or corrosion. Cracks or damage to the reservoir or lines can allow air to enter the system, causing problems with the brakes. If you notice any damage or corrosion, replace the affected components promptly.

By maintaining proper brake fluid levels and condition, you can help prevent air from entering the brake system and ensure safe and reliable braking performance. Remember, brake safety is crucial, and neglecting to maintain proper brake fluid levels can have serious consequences. If you’re unsure about how to check brake fluid levels or condition, consult a professional mechanic or brake specialist for guidance.

Regular brake fluid checks and maintenance can also help prevent common brake problems, such as spongy brake pedals and increased stopping distances. By staying on top of brake fluid maintenance, you can help ensure your vehicle’s brakes are functioning properly and reduce the risk of accidents.

How to Check for Air in Your Brake Lines and Hoses

Inspecting brake lines and hoses for signs of damage, corrosion, or blockages is a crucial step in diagnosing and fixing spongy brakes. Air can enter the brake system through damaged or corroded brake lines and hoses, causing a range of problems, including spongy brake pedals and increased stopping distances. To check for air in your brake lines and hoses, follow these steps:

First, locate the brake lines and hoses, which are usually located near the brake calipers and master cylinder. Inspect the lines and hoses for signs of damage, such as cracks, frays, or corrosion. Check for any blockages, such as kinks or twists, that can restrict brake fluid flow.

Next, use a brake line tester or a pressure gauge to detect air leaks. A brake line tester is a specialized tool that can detect air leaks in the brake lines and hoses. A pressure gauge can also be used to detect air leaks by measuring the pressure in the brake system. If the pressure is lower than recommended, it may indicate an air leak.

To use a brake line tester, attach the tester to the brake line or hose and pressurize the system. The tester will indicate if there is an air leak present. To use a pressure gauge, attach the gauge to the brake line or hose and measure the pressure. Compare the reading to the recommended pressure specification.

If you detect an air leak, it’s essential to repair or replace the damaged brake line or hose. Air leaks can cause serious problems with the brake system, including spongy brake pedals and increased stopping distances. By inspecting brake lines and hoses regularly, you can help prevent air from entering the brake system and ensure safe and reliable braking performance.

In addition to inspecting brake lines and hoses, it’s also essential to check the brake fluid level and condition. Low brake fluid levels or contaminated fluid can also cause air to enter the system. By maintaining proper brake fluid levels and condition, you can help prevent air from entering the brake system and ensure safe and reliable braking performance.

By following these steps, you can help diagnose and fix spongy brakes caused by air in the brake system. Remember, brake safety is crucial, and neglecting to inspect brake lines and hoses can have serious consequences. If you’re unsure about how to inspect brake lines and hoses or detect air leaks, consult a professional mechanic or brake specialist for guidance.

The Role of Master Cylinder and Brake Caliper in Brake Bleeding

The master cylinder and brake caliper are two critical components in the brake system that play a crucial role in brake bleeding. The master cylinder is responsible for converting non-hydraulic pressure from the brake pedal into hydraulic pressure that is transmitted to the brake calipers. The brake calipers, on the other hand, are responsible for applying the brakes by clamping the brake pads onto the rotor.

Both the master cylinder and brake caliper can contribute to air entering the brake system, which can cause a range of problems, including spongy brake pedals and increased stopping distances. To prevent air from entering the brake system, it’s essential to inspect and maintain these components regularly.

Inspecting the master cylinder involves checking for signs of damage, corrosion, or wear. Look for any cracks, rust, or corrosion on the master cylinder body or piston. Also, check the master cylinder seals for any signs of damage or wear. If you find any damage or wear, replace the master cylinder promptly.

Inspecting the brake caliper involves checking for signs of damage, corrosion, or wear on the caliper body, piston, and seals. Look for any cracks, rust, or corrosion on the caliper body or piston. Also, check the caliper seals for any signs of damage or wear. If you find any damage or wear, replace the brake caliper promptly.

In addition to inspecting the master cylinder and brake caliper, it’s also essential to check the brake fluid level and condition. Low brake fluid levels or contaminated fluid can cause air to enter the system, which can lead to a range of problems. By maintaining proper brake fluid levels and condition, you can help prevent air from entering the brake system and ensure safe and reliable braking performance.

By understanding the role of the master cylinder and brake caliper in brake bleeding, you can take steps to prevent air from entering the brake system and ensure safe and reliable braking performance. Remember, brake safety is crucial, and neglecting to inspect and maintain these components can have serious consequences. If you’re unsure about how to inspect or maintain the master cylinder or brake caliper, consult a professional mechanic or brake specialist for guidance.

Regular maintenance of the master cylinder and brake caliper can also help prevent common brake problems, such as spongy brake pedals and increased stopping distances. By staying on top of maintenance, you can help ensure your vehicle’s brakes are functioning properly and reduce the risk of accidents.

A Step-by-Step Guide to Bleeding Your Brakes

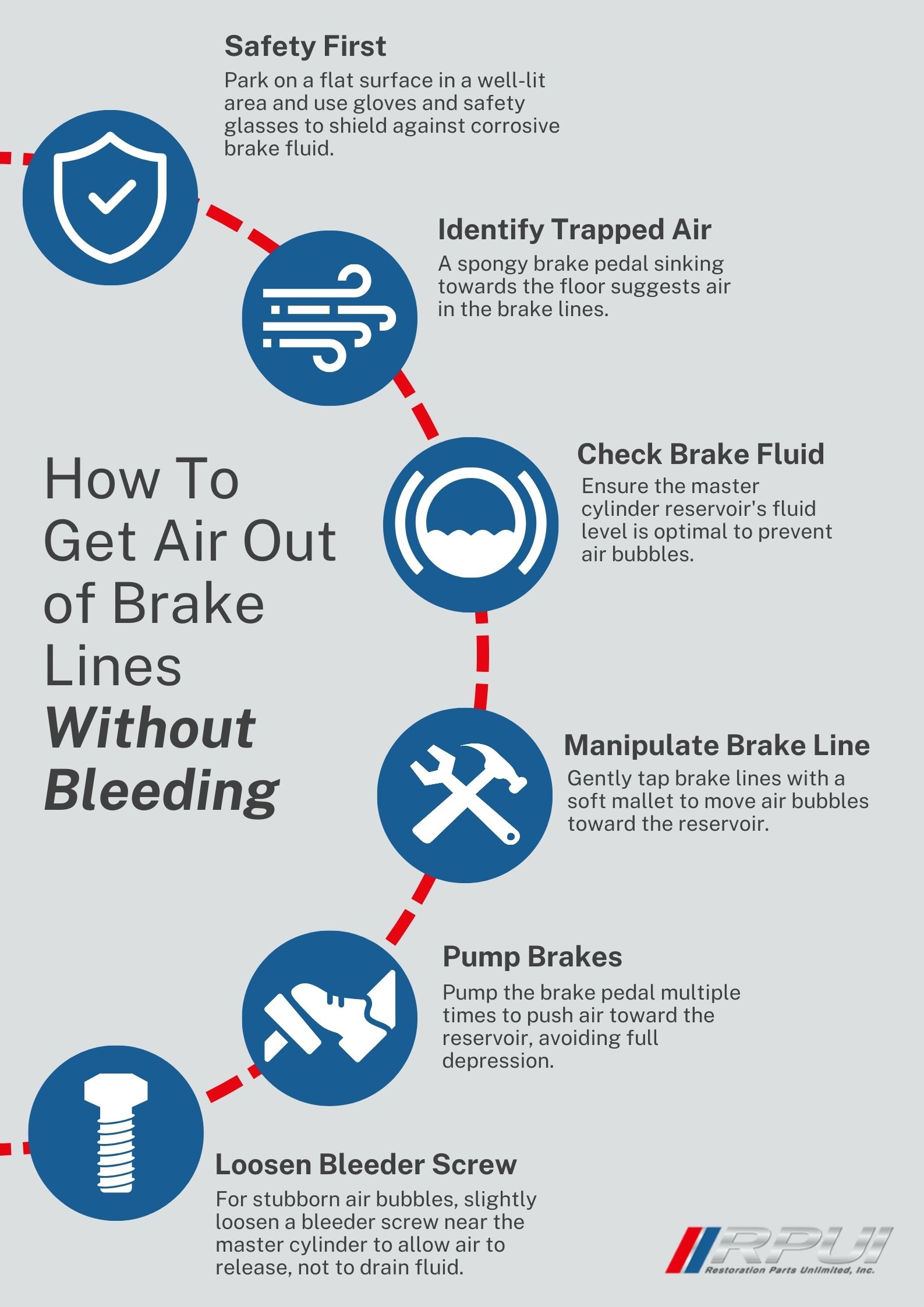

Bleeding your brakes is a relatively straightforward process that can be done at home with the right tools and materials. However, it’s essential to follow the correct procedure to ensure that the brake system is properly bled and that there are no air pockets left in the system.

Before you start, make sure you have the following tools and materials:

- Brake fluid

- Brake bleeding kit

- Brake line wrench

- Rubber hose

- Container for old brake fluid

Step 1: Jack up the vehicle and remove the wheels to access the brake calipers. Make sure the vehicle is securely supported by jack stands and that the parking brake is engaged.

Step 2: Locate the brake caliper and remove the caliper bolts. Use a wrench to loosen the bolts, then remove them completely.

Step 3: Use a rubber hose to attach the brake bleeding kit to the brake caliper. Make sure the hose is securely attached to prevent any air from entering the system.

Step 4: Pump the brake pedal several times to build up pressure in the brake system. Then, use the brake bleeding kit to release the pressure and allow the old brake fluid to flow out.

Step 5: Continue to pump the brake pedal and release the pressure until the old brake fluid has been completely removed and replaced with new fluid.

Step 6: Once the brake system has been properly bled, use a wrench to tighten the caliper bolts. Make sure they are securely tightened to prevent any air from entering the system.

Step 7: Repeat the process for each brake caliper, making sure to bleed the system completely before moving on to the next caliper.

By following these steps, you can ensure that your brake system is properly bled and that there are no air pockets left in the system. Remember to always refer to your vehicle’s repair manual for specific instructions on how to bleed your brakes.

It’s also important to note that brake bleeding can be a messy process, so make sure to have a container on hand to catch any old brake fluid that may spill out during the process. Additionally, make sure to dispose of the old brake fluid properly to prevent any environmental harm.

Troubleshooting Common Brake Bleeding Problems

During the brake bleeding process, several issues can arise that can prevent the brake system from being properly bled. In this section, we will discuss some common problems that may occur and provide tips on how to troubleshoot and resolve them.

One common issue that can occur during brake bleeding is the presence of air pockets in the brake lines. Air pockets can prevent the brake fluid from flowing properly, leading to spongy brake pedals and reduced braking performance. To resolve this issue, try bleeding the brake lines again, making sure to use a brake bleeding kit and following the manufacturer’s instructions.

Another common problem that can occur during brake bleeding is clogged brake lines. Clogged brake lines can prevent the brake fluid from flowing properly, leading to reduced braking performance. To resolve this issue, try cleaning the brake lines with a brake line cleaner or replacing them if they are damaged.

Faulty master cylinders can also cause problems during the brake bleeding process. A faulty master cylinder can prevent the brake fluid from flowing properly, leading to reduced braking performance. To resolve this issue, try replacing the master cylinder with a new one.

In addition to these common problems, there are several other issues that can arise during the brake bleeding process. These include brake fluid leaks, clogged brake calipers, and faulty brake sensors. To resolve these issues, try troubleshooting the problem and consulting a repair manual or a professional mechanic if necessary.

By being aware of these common problems and knowing how to troubleshoot and resolve them, you can ensure that your brake system is properly bled and functioning safely and reliably. Remember to always refer to your vehicle’s repair manual for specific instructions on how to bleed your brakes and troubleshoot common problems.

Regular brake maintenance is essential to ensure safe and reliable braking performance. By following the tips and guidelines outlined in this article, you can help prevent common brake problems and ensure that your vehicle’s brakes are functioning properly.

Preventing Air from Entering Your Brake System in the Future

Preventing air from entering your brake system is crucial to ensure safe and reliable braking performance. By following a few simple tips, you can help prevent air from entering your brake system and avoid the need for brake bleeding.

Regular brake fluid checks are essential to prevent air from entering your brake system. Check your brake fluid levels regularly and top them off if necessary. Make sure to use the correct type of brake fluid for your vehicle, as specified in your owner’s manual.

Proper brake line and hose maintenance is also important to prevent air from entering your brake system. Inspect your brake lines and hoses regularly for signs of damage, corrosion, or blockages. Replace them if necessary, and make sure to use the correct type of brake lines and hoses for your vehicle.

Avoiding common mistakes that can lead to air entering your brake system is also important. Make sure to tighten all brake line and hose connections securely, and avoid over-tightening them, which can cause damage to the brake lines and hoses.

Additionally, make sure to use a brake bleeding kit that is specifically designed for your vehicle’s brake system. This will help ensure that the brake system is properly bled and that air is removed from the system.

By following these tips, you can help prevent air from entering your brake system and ensure safe and reliable braking performance. Remember, regular brake maintenance is essential to prevent brake problems and ensure your safety on the road.

It’s also important to note that brake maintenance is not just limited to brake bleeding. Regular inspections of your brake pads, rotors, and other brake components can help identify potential problems before they become major issues.

By making brake maintenance a priority, you can help ensure your safety on the road and avoid costly repairs down the road. Remember, brake safety is crucial, and neglecting brake maintenance can have serious consequences.

Conclusion: The Importance of Regular Brake Maintenance

Regular brake maintenance is crucial to ensure safe and reliable braking performance. By following the steps outlined in this article, you can help prevent air from entering your brake system and ensure that your brakes are functioning properly.

Remember, brake safety is not just about preventing accidents, it’s also about preventing costly repairs. By making brake maintenance a priority, you can help extend the life of your brake components and avoid costly repairs down the road.

In addition to brake bleeding, regular inspections of your brake pads, rotors, and other brake components can help identify potential problems before they become major issues. By staying on top of brake maintenance, you can help ensure your safety on the road and avoid costly repairs.

Don’t wait until it’s too late to address brake problems. By following the tips and guidelines outlined in this article, you can help prevent air from entering your brake system and ensure safe and reliable braking performance.

Regular brake maintenance is essential to ensure your safety on the road. By making brake maintenance a priority, you can help prevent accidents and costly repairs. Remember, brake safety is crucial, and neglecting brake maintenance can have serious consequences.

By following the steps outlined in this article, you can help ensure that your brakes are functioning properly and that you’re safe on the road. Don’t wait until it’s too late to address brake problems – make brake maintenance a priority today.