The Advantage of Hydraulic Disc Brakes for Cyclists

Hydraulic disk brakes for bicycles have gained popularity among cyclists due to their superior performance and safety features. Compared to traditional braking systems, hydraulic disc brakes offer enhanced stopping power, durability, and modulation. These advantages translate to improved control and confidence for cyclists, especially in challenging weather conditions and diverse terrain types.

Key Components of Hydraulic Disc Brake Systems

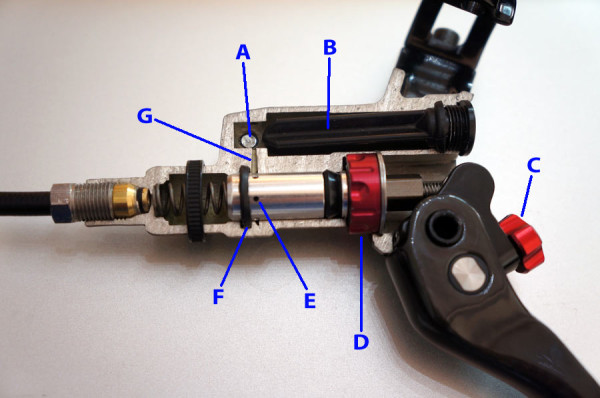

Hydraulic disc brake systems consist of several essential components that work together to provide reliable and efficient braking performance. These components include the brake lever, master cylinder, hose, caliper, and rotor. The brake lever, typically made of aluminum or carbon fiber, is the rider’s primary point of interaction, translating hand movements into hydraulic pressure.

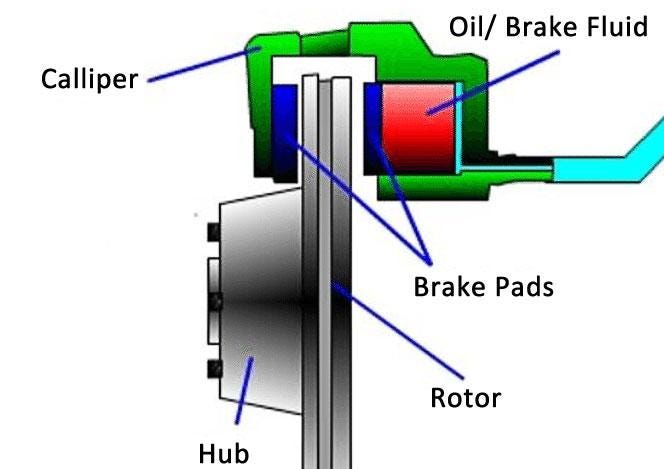

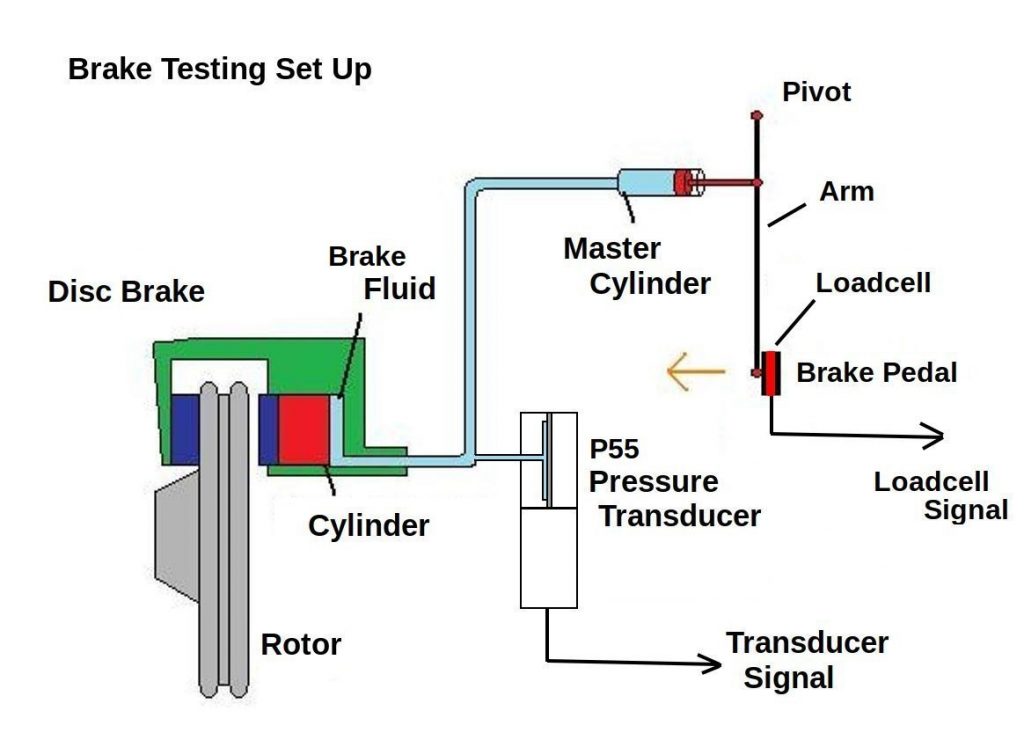

The master cylinder, usually integrated into the brake lever, converts mechanical force into hydraulic pressure. This pressure is transmitted through a flexible hose, which is resistant to wear, tear, and environmental factors. The hydraulic caliper, located near the wheel, houses the brake pads and pistons. When the brake lever is actuated, the hydraulic fluid forces the pistons to move, squeezing the brake pads against the rotor.

Rotors are typically made of steel or a steel alloy and are mounted to the wheel hub. They dissipate heat generated during braking and provide a large surface area for the brake pads to grip. High-quality materials and precise manufacturing processes ensure the longevity and performance of these components. By understanding the functions and materials used in hydraulic disc brake systems, cyclists can make informed decisions when selecting and maintaining their brakes.

Selecting the Perfect Hydraulic Disc Brake for Your Bicycle

When choosing hydraulic disc brakes for your bicycle, consider several factors to ensure optimal performance and compatibility. First, decide between mechanical and hydraulic brake types. Mechanical brakes use a cable to actuate the brake, while hydraulic brakes use fluid. Hydraulic systems generally offer better modulation and power but require more maintenance.

Next, consider the mount type. Post mount brakes are more common on mountain bikes and older road bikes, while flat mount brakes are typically found on modern road and gravel bikes. Rotor size is another essential factor, with 140mm, 160mm, and 180mm being common options. Larger rotors provide more stopping power but add weight and rotational mass. Pad material is also crucial, with organic and sintered metallic options available. Organic pads offer better modulation and less noise but wear faster in wet conditions, while sintered metallic pads are more durable and perform better in wet weather.

Popular brands offering hydraulic disc brakes include Shimano, SRAM, and Campagnolo. Shimano’s lineup includes the XT and XTR models, while SRAM offers the Guide RE and Level TLM. Campagnolo’s H11 hydraulic disc brakes are designed for high-performance road bikes. When selecting a hydraulic disc brake system, consider your budget, riding style, and bike compatibility to make an informed decision.

How to Install Hydraulic Disc Brakes on Your Bicycle

Installing hydraulic disc brakes on your bicycle requires careful attention to safety precautions and the proper use of tools. Begin by gathering the necessary tools, including a torque wrench, Allen keys, cable cutters, and brake fluid. Ensure your work area is clean and well-lit to prevent contamination and accidents.

Step 1: Remove the old braking system, taking care to preserve the brake lever and shifter compatibility. Step 2: Install the hydraulic brake caliper, aligning it with the rotor and securing it with the appropriate bolts. Use a torque wrench to ensure proper tightness and prevent damage to the frame or fork.

Step 3: Route the hydraulic hose, ensuring it is not kinked or pinched. Attach the hose to the frame or fork using zip ties or clamps. Step 4: Install the rotor, ensuring it is centered and true. Tighten the rotor bolts to the recommended torque.

Step 5: Bleed the brakes to remove air from the hydraulic system. Follow the manufacturer’s instructions for this process, as it may vary between brands. Step 6: Adjust the brake lever for optimal reach and modulation. Use the barrel adjuster on the brake lever or at the caliper to fine-tune the cable tension.

Step 7: Test the brakes, ensuring they function properly and smoothly. Check for leaks, and re-bleed the brakes if necessary. Step 8: Reinstall the wheel and double-check the brake alignment and tension. With these steps, you can successfully install hydraulic disc brakes on your bicycle.

Maintenance and Troubleshooting Tips for Hydraulic Disc Brakes

Regular maintenance and troubleshooting are crucial for optimal performance and longevity of hydraulic disc brakes on your bicycle. Begin by inspecting the system for leaks, contamination, and wear. Check the brake pads for adequate thickness and replace them if necessary.

Bleeding the brakes is an essential maintenance task. Over time, air can enter the hydraulic system, reducing braking performance. Follow the manufacturer’s instructions for bleeding the brakes, using the appropriate tools and brake fluid. Regularly inspect the hose for damage or wear, and replace it if necessary.

Common issues with hydraulic disc brakes include brake squeal, brake fade, and contamination. Brake squeal can be caused by glazing, contamination, or poor pad alignment. To address brake squeal, clean the rotor and pads, true the rotor, and adjust the pad alignment. Brake fade can be caused by overheating or contamination. To prevent brake fade, avoid excessive braking, and ensure the rotor and pads are clean and well-maintained.

Contamination can occur from dirt, debris, or oil. To prevent contamination, keep the system clean and avoid touching the rotor or pads with dirty hands. If contamination occurs, clean the system thoroughly, and replace the pads if necessary. Regular maintenance and troubleshooting can ensure optimal performance and longevity of your hydraulic disc brakes.

Real-Life Reviews of Top-Rated Hydraulic Disc Brakes

Hydraulic disc brakes have gained popularity among cyclists due to their superior performance and safety features. Here are some real-life reviews of top-rated hydraulic disc brakes, comparing their features, performance, and price.

Shimano XT M8100 Hydraulic Disc Brake: The Shimano XT M8100 is a popular choice among mountain bikers, offering excellent modulation and stopping power. Its two-piston design is suitable for most trail riding applications. Users praise its reliability, ease of bleeding, and tool-free reach adjustment. The Shimano XT M8100 retails for around $130 per wheel.

SRAM Level TLM Hydraulic Disc Brake: The SRAM Level TLM is a lightweight and powerful hydraulic disc brake, featuring a two-piston design. It offers excellent modulation and heat management, making it suitable for long descents. Users appreciate its lightweight construction, easy setup, and tool-free reach adjustment. The SRAM Level TLM retails for around $150 per wheel.

Magura MT5 Hydraulic Disc Brake: The Magura MT5 is a versatile hydraulic disc brake, featuring a four-piston design for maximum stopping power. It is suitable for enduro and downhill riding applications. Users praise its adjustable lever reach, bite point, and tool-free pad adjustment. The Magura MT5 retails for around $140 per wheel.

These are just a few examples of top-rated hydraulic disc brakes on the market. When selecting a hydraulic disc brake, consider your riding style, budget, and bike compatibility. Consult user reviews and expert opinions to make an informed decision. By investing in high-quality hydraulic disc brakes, you can enhance your cycling experience and ensure superior performance and safety on the road or trail.

Comparing Hydraulic Disc Brakes with Other Brake Types

When selecting the best braking system for your bicycle, it’s essential to compare hydraulic disc brakes with other brake types, such as mechanical disc brakes, rim brakes, and coaster brakes. Each system has its advantages and disadvantages, and understanding these differences can help you make an informed decision.

Hydraulic Disc Brakes vs. Mechanical Disc Brakes: Hydraulic disc brakes offer superior modulation, power, and consistency compared to mechanical disc brakes. They use fluid to transmit force from the lever to the caliper, resulting in a more responsive and reliable braking system. However, hydraulic disc brakes require more maintenance and are generally more expensive than mechanical disc brakes. Mechanical disc brakes, on the other hand, use a cable to actuate the caliper, making them easier to install and maintain but less powerful and consistent than hydraulic disc brakes.

Hydraulic Disc Brakes vs. Rim Brakes: Rim brakes have been the standard braking system for bicycles for many years. They are lightweight, easy to maintain, and affordable. However, they have several disadvantages compared to hydraulic disc brakes. Rim brakes are less effective in wet or muddy conditions, and they can wear out the rim over time. Hydraulic disc brakes, on the other hand, offer superior stopping power, modulation, and consistency in various weather conditions and terrain types. They also don’t wear out the rim, resulting in a longer-lasting braking system.

Hydraulic Disc Brakes vs. Coaster Brakes: Coaster brakes are a type of rear brake that is actuated by pedaling backward. They are simple, affordable, and easy to maintain. However, they have several disadvantages compared to hydraulic disc brakes. Coaster brakes are less effective in wet or muddy conditions, and they don’t offer the same level of modulation and stopping power as hydraulic disc brakes. Additionally, coaster brakes can make it difficult to perform tricks or maneuvers that require pedaling backward.

In conclusion, hydraulic disc brakes offer superior performance and safety features compared to other brake types. While they may be more expensive and require more maintenance, their advantages in various weather conditions and terrain types make them an excellent investment for serious cyclists. When selecting a braking system for your bicycle, consider your riding style, budget, and bike compatibility to make an informed decision.