Why Knowing Your Wheel Size Is Crucial

Accurately measuring a bicycle wheel is essential for several reasons. Choosing the correct tires depends on knowing your wheel size. Incorrect sizing leads to problems like brake rubbing or poor shifting performance. Furthermore, understanding your wheel dimensions ensures compatibility with various bike components and contributes to optimal gear ratios. This process of measuring a bicycle wheel is vital for achieving peak cycling performance and safety. Knowing your wheel size is fundamental for making informed decisions about maintenance and upgrades. Proper tire selection prevents mechanical issues and improves riding comfort.

The importance of measuring a bicycle wheel extends beyond tire selection. It helps determine compatibility with different frames and components. For example, when selecting new wheels or upgrading parts, precise measurements are necessary to avoid costly mistakes. Inaccurate sizing can affect shifting efficiency, causing issues like chain slippage or difficulty changing gears. This could compromise your riding experience and even lead to safety risks. Therefore, understanding how to correctly measure a bicycle wheel is a key skill for any cyclist.

Beyond immediate compatibility issues, understanding wheel size plays a crucial role in calculating gear ratios. Correct gear ratios are essential for optimal performance, allowing cyclists to efficiently tackle varied terrains and maintain appropriate speeds. Knowing the wheel circumference, determined through measuring a bicycle wheel, is directly linked to distance calculations. For serious cyclists, accurately tracking distance and speed is crucial for training and performance analysis. Mastering the process of measuring a bicycle wheel empowers cyclists to make informed choices and optimize their riding experience.

Essential Tools for Accurate Measurement

Accurately measuring a bicycle wheel requires the right tools. A flexible tape measure proves invaluable for obtaining overall dimensions. Its flexibility allows for accurate measurement around curves, crucial when measuring a bicycle wheel’s diameter. Ensure the tape measure is in good condition; a worn or stretched tape will lead to inaccurate readings. For more precise measurements, especially when dealing with the rim, calipers offer superior accuracy. Calipers allow for precise measurements of smaller components, helping in measuring the rim diameter accurately. Remember to use calipers carefully to avoid pinching or damaging the rim. While not strictly essential for measuring a bicycle wheel, a wheel gauge can simplify the process if available. A wheel gauge provides direct readings of wheel sizes, removing the need for manual calculations. However, a tape measure and potentially calipers are sufficient for most home mechanics. Using the appropriate tools ensures accurate results when measuring a bicycle wheel, leading to correct tire selection and optimal bike performance.

When measuring a bicycle wheel, prioritize safety. Always handle tools with care. Avoid applying excessive force, which could damage the wheel or the measuring tools. Keep your fingers clear of moving parts during the measuring process. A steady hand and a well-lit workspace will improve accuracy. Take multiple measurements to confirm results. Comparing readings from multiple attempts can help detect and rectify inaccuracies. Take your time and concentrate; haste often results in errors. This careful approach significantly contributes to the accuracy of your measurements for measuring a bicycle wheel, ensuring the information is reliable for future parts selection and maintenance. Pay attention to detail; even small discrepancies can affect the overall accuracy of measuring a bicycle wheel and impact decisions about maintenance and repairs.

Proper tool usage directly impacts the success of measuring a bicycle wheel. For instance, when using a tape measure, ensure it’s pulled taut but not stretched. A slack tape measure provides inaccurate readings, leading to incorrect calculations for determining a bicycle wheel’s diameter or circumference. Calipers should be applied firmly but gently to the rim to get an accurate reading. Avoid any undue pressure that could distort the rim’s shape or damage the calipers. When using a wheel gauge (if available), make sure the wheel is correctly positioned within the gauge before taking a reading. Understanding the proper application of these tools ensures reliable results in measuring a bicycle wheel, reducing the chances of costly errors in parts selection or repairs. Take the time to learn how to use each tool effectively before beginning the measurement process for measuring a bicycle wheel.

How to Measure Your Bicycle Wheel Diameter

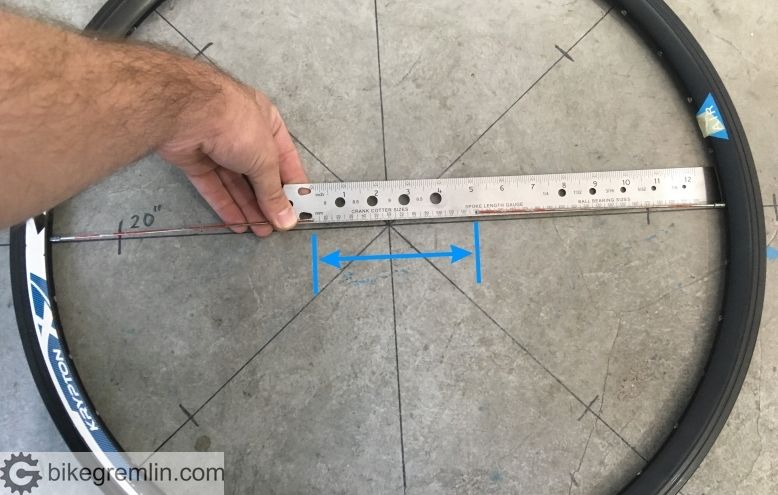

Accurately measuring a bicycle wheel is crucial for various reasons. Begin by gathering your tools: a flexible tape measure is essential for measuring the wheel’s overall diameter. A caliper can provide more precise measurements of the rim itself. Ensure the tire is properly inflated to its recommended pressure for consistent results during measuring a bicycle wheel. To measure the overall diameter, carefully wrap the tape measure around the widest part of the wheel, encompassing both the tire and the rim. Take note of this measurement; it represents the wheel’s total diameter. Remember to measure across the center of the wheel to get the most accurate reading when measuring a bicycle wheel. This measurement, including the tire, is important for determining things like tire clearance and overall bike fit.

Next, focus on measuring the rim diameter. This measurement excludes the tire. Use a caliper for a more precise measurement, taking readings at several points across the rim’s edge to ensure accuracy. This provides a different dimension and is critical for determining rim compatibility and selecting appropriate replacement parts. Understanding both the overall diameter (including tire) and the rim diameter are necessary for tasks like accurately measuring a bicycle wheel, choosing replacement rims, and determining suitable tires. The difference between these two measurements highlights the tire’s contribution to the total wheel diameter.

Accurate measuring a bicycle wheel requires attention to detail and correct technique. Avoid stretching or twisting the tape measure, as this will skew the results. For the most accurate readings, ensure the tape measure lies flat against the wheel’s surface. Repeat measurements several times at different points to minimize errors and ensure consistency. Compare your measurements with the markings on the wheel or tire, which often indicate the size according to industry standards. Understanding how to measure a bicycle wheel properly helps in selecting compatible tires and components for optimal performance and safety. Mastering this skill ensures you maintain the best possible setup for your bicycle.

Determining Your Wheel’s Circumference

Calculating the circumference of your bicycle wheel is a simple yet crucial step in measuring a bicycle wheel accurately. The circumference, the distance around the wheel, is easily determined using the diameter you previously measured. The formula is: Circumference = πd, where ‘d’ represents the diameter of the wheel. To perform this calculation, use the value of pi (π) as approximately 3.14159. This ensures a high level of accuracy when measuring a bicycle wheel. Remember to use the diameter that includes the tire, as this represents the actual rolling diameter.

For example, if the diameter of your bicycle wheel (including the tire) is 700 millimeters, the circumference is calculated as follows: Circumference = 3.14159 x 700 mm = 2199.113 mm. This measurement is essential for various applications. Knowing the circumference helps in determining the distance traveled. For instance, one complete rotation of the wheel covers a distance equal to its circumference. This is useful for calculating odometer readings, or for figuring out how far you have cycled during a trip. Understanding how to perform this simple calculation is key to accurately measuring a bicycle wheel for various purposes. The accuracy of this calculation directly affects the precision of any calculations related to distance or speed.

Precisely measuring a bicycle wheel’s circumference is important for several reasons. Cyclists use this data to calibrate cycling computers and determine speed and distance travelled. Mechanics need this information to ensure proper gear ratios. Accurate circumference data is also critical for selecting appropriate replacement tires and tubes. Using the correct formula and the most precise value for pi are key to ensure your calculations are as accurate as possible when measuring a bicycle wheel. Remember that even small errors in measurement can accumulate and lead to significant discrepancies over time. The process of measuring a bicycle wheel requires attention to detail to yield accurate results.

Understanding Wheel Size Standards (ISO and ETRTO)

Accurately measuring a bicycle wheel relies on understanding the standardized systems used to describe wheel sizes. The International Organization for Standardization (ISO) and the European Tyre and Rim Technical Organisation (ETRTO) are the key players. These organizations define wheel and tire dimensions, ensuring compatibility between components. Ignoring these standards can lead to problems when fitting tires or other parts. When measuring a bicycle wheel, familiarity with these standards is crucial for selecting the correct replacement parts.

ETRTO sizing, commonly found on modern bicycle wheels and tires, uses millimeters to express the wheel’s rim diameter and the tire’s width. For example, a 622-17 designation indicates a 622mm rim diameter, which is a common road bike size, and that this is a 17mm width tire that will fit this rim. ISO sizing uses inches, but the measurements are not always a straightforward conversion from millimeters and may not accurately reflect the actual dimensions of the measuring a bicycle wheel. Both systems are important to understand when correctly measuring a bicycle wheel, to ensure proper component selection. This system is crucial when measuring a bicycle wheel for replacement parts.

Interpreting markings on your wheel and tire is essential. Look for numbers and letters that indicate the size according to either ETRTO or ISO standards. These markings are critical when you are measuring a bicycle wheel and selecting replacement tires and rims. For instance, a tire might be labeled “700 x 25C,” which indicates a tire designed for a 700c rim. When measuring a bicycle wheel, cross-referencing the measurements with the markings will verify the accuracy of your measurements and aid in selecting compatible components. Understanding these standards is essential for accurate measuring a bicycle wheel and ensuring proper component selection. The process of measuring a bicycle wheel benefits from a clear understanding of these systems.

Identifying Your Wheel’s Type (Road, Mountain, etc.)

The type of bicycle significantly influences the appropriate wheel size. Measuring a bicycle wheel accurately is crucial for selecting compatible components. Road bikes typically utilize smaller diameter wheels, ranging from 650c to 700c, prioritizing speed and efficiency on paved surfaces. These smaller wheels offer less rolling resistance. Understanding wheel size is essential when measuring a bicycle wheel for road bikes. The thinner tires contribute to lower weight and improved aerodynamics. This contrasts with mountain bikes, which often feature larger diameter wheels, such as 26″, 27.5″, or 29″, providing greater stability and traction on rough terrain. The larger surface area of mountain bike tires improves grip and helps absorb shocks. When measuring a bicycle wheel for a mountain bike, the increased size must be factored into the process.

Hybrid bikes, designed for a blend of on-road and off-road riding, usually incorporate wheel sizes between those of road and mountain bikes. They frequently utilize 700c wheels with wider tires. The versatility of hybrid bikes reflects their adaptable wheel size. Measuring a bicycle wheel on a hybrid requires attention to the tire width as well as the rim diameter. Other bicycle types, such as cyclocross bikes, touring bikes, and BMX bikes, have specific wheel size preferences. Cyclocross bikes often feature 700c wheels for efficiency on varied surfaces. Touring bikes typically utilize sturdy 700c wheels to support heavy loads. BMX bikes commonly use smaller wheels, around 20″, tailored for maneuverability and stunts. For any bike type, knowing the wheel type aids in selecting the right tools and techniques when measuring a bicycle wheel.

Choosing the correct wheel size is vital for optimal performance and safety. Using the wrong size can lead to poor shifting, brake rubbing, or even structural damage. When measuring a bicycle wheel, consider the bike’s intended use and the associated wheel size standards to ensure compatibility with tires and other components. Accurate measurement is paramount for ensuring proper functionality and safe riding. Properly measuring a bicycle wheel is a fundamental skill for any cyclist. Incorrect sizing compromises performance and potentially safety. Precise measurements are key for finding the correct replacement parts and ensuring compatibility across all components of the bicycle.

Measuring Your Tire’s Dimensions: A Crucial Step in Understanding Your Bicycle Wheel

Accurately measuring your tire’s dimensions is just as important as measuring a bicycle wheel itself. Tire size significantly impacts performance, comfort, and compatibility with your frame and other components. Two key measurements are crucial: width and diameter. To measure the tire width, use a caliper to measure the distance across the widest part of the tire. Record this measurement in millimeters. Remember to ensure the tire is properly inflated to obtain an accurate reading. Incorrect tire pressure can significantly affect the width measurement.

Measuring the tire diameter involves using a flexible tape measure to find the distance across the tire from the ground to the top, ensuring the wheel is in a vertical position. This measurement, also in millimeters, is taken from the very top of the tire tread to the ground. Note that the tire diameter will be slightly larger than the rim diameter. Understanding both the tire and rim diameters is vital when determining compatibility with various components, particularly when considering tire clearance within the frame. This measurement helps in assessing whether a larger or smaller tire can be used while avoiding rubbing against the frame or fork.

The relationship between tire size and wheel size is critical. They work in tandem to determine the overall rolling diameter of the wheel. This, in turn, affects gear ratios, speedometer accuracy, and overall riding experience. Properly measuring both tire and wheel dimensions ensures you can select compatible parts and achieve optimal performance from your bicycle. Remember, when measuring a bicycle wheel, consider both the wheel itself and the tire; they are interconnected elements that determine your bicycle’s fit and efficiency.

Troubleshooting Common Measurement Issues When Measuring a Bicycle Wheel

Inaccurate measurements during the process of measuring a bicycle wheel often stem from inconsistent tire pressure. Proper inflation is crucial. Under-inflated tires will yield a larger diameter measurement than correctly inflated ones. Conversely, over-inflation can slightly reduce the measured diameter. Always inflate your tires to the manufacturer’s recommended pressure before beginning. This ensures consistent and accurate results when measuring a bicycle wheel. Using a reliable pressure gauge is essential for this step. Remember to check the tire pressure before and after measuring to ensure it remains constant throughout the process.

Another common problem arises from using inappropriate tools or improper measuring techniques. A flexible tape measure is best for measuring the overall diameter, including the tire. However, for precise rim measurements, calipers provide superior accuracy. Ensure the tape measure is taut but not overly stretched when measuring a bicycle wheel; this prevents inaccurate readings. When using calipers, ensure proper alignment and a firm grip to avoid slippage. Incorrect placement of the measuring tools can lead to significant errors. Pay close attention to details when measuring a bicycle wheel, making sure the measuring tool is correctly positioned, and double-checking measurements to minimize errors.

Inconsistencies in your measurements might also indicate a problem with the wheel itself. A bent rim, for example, will significantly affect the diameter readings. Visually inspect the wheel for any damage or irregularities before beginning your measurements. If you notice any significant deviations or if your measurements seem inconsistent despite careful attention to technique and inflation, consider seeking professional assistance from a bicycle mechanic. They can identify any underlying issues with your wheel and provide expert advice on measuring a bicycle wheel accurately. Remember, precise measurements are critical when selecting replacement tires or components.