Understanding the Basics of Brake Pads

Brake pads are a crucial component of a vehicle’s braking system, playing a vital role in ensuring the safety and performance of the vehicle. When it comes to choosing the right brake pads, two main types come to mind: sintered and ceramic. While both types have their own set of advantages and disadvantages, understanding the basics of brake pads is essential to making an informed decision. In this article, we will delve into the world of sintered vs ceramic brake pads, exploring their differences, benefits, and drawbacks.

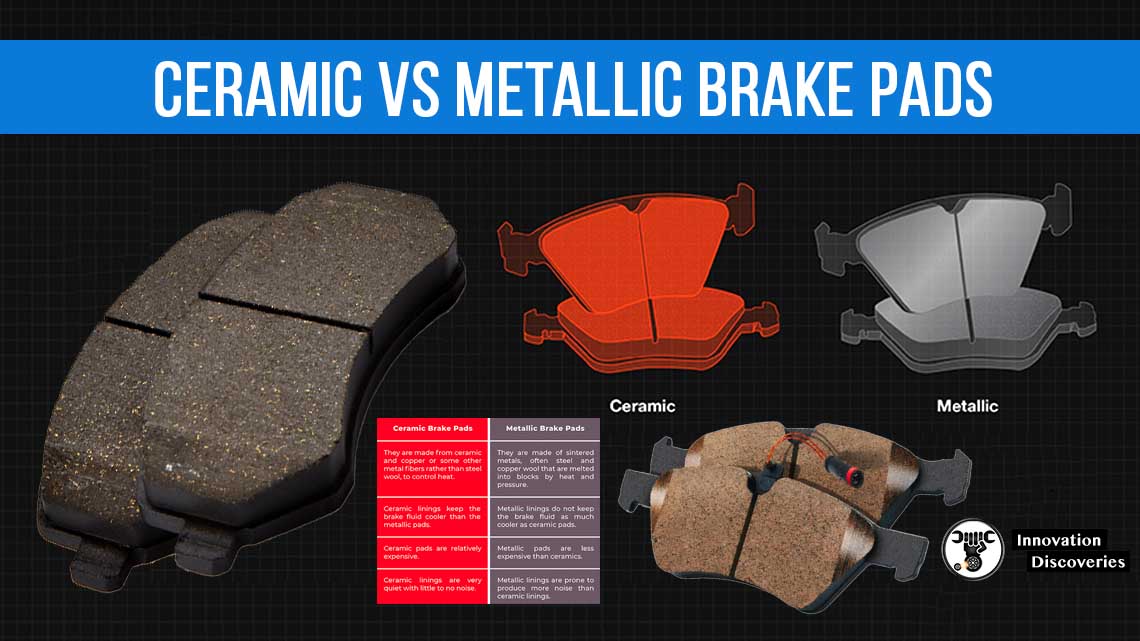

Brake pads are designed to withstand the intense heat and friction generated by the braking process. They are typically made from a combination of materials, including metals, ceramics, and other compounds. The type of brake pad used can significantly impact the vehicle’s braking performance, fuel efficiency, and overall safety. Sintered brake pads, for instance, are known for their durability and heat resistance, making them a popular choice for heavy-duty applications. On the other hand, ceramic brake pads are praised for their quiet operation and low dust production, making them a favorite among drivers who value a smooth and quiet ride.

When it comes to sintered vs ceramic brake pads, the main difference lies in their composition and manufacturing process. Sintered brake pads are made using a process called sintering, where metal powders are compressed and heated to form a solid bond. This process creates a strong and durable brake pad that can withstand high temperatures and heavy use. Ceramic brake pads, on the other hand, are made from a combination of ceramic fibers and other materials, which are designed to provide a smooth and quiet braking experience.

In the next section, we will explore the factors to consider when choosing the right brake pads for your vehicle, including driving habits, climate, and vehicle type. By understanding these factors and the differences between sintered and ceramic brake pads, you can make an informed decision that meets your vehicle’s specific needs.

How to Choose the Right Brake Pads for Your Vehicle

When it comes to selecting the right brake pads for your vehicle, several factors come into play. Understanding these factors is crucial to making an informed decision that meets your vehicle’s specific needs. In this section, we will explore the key considerations to keep in mind when choosing between sintered vs ceramic brake pads.

One of the most important factors to consider is your driving habits. If you drive aggressively or frequently engage in stop-and-go traffic, you may require brake pads that can withstand high temperatures and heavy use. In this case, sintered brake pads may be the better choice due to their durability and heat resistance. On the other hand, if you drive primarily on the highway or in light traffic, ceramic brake pads may be a better option due to their quiet operation and low dust production.

Climate is another important factor to consider when choosing brake pads. If you live in an area with extreme temperatures, you may require brake pads that can withstand these conditions. Sintered brake pads, for example, are designed to perform well in high-temperature environments, while ceramic brake pads may be more suitable for colder climates.

Vehicle type is also an important consideration when choosing brake pads. If you own a heavy-duty vehicle or a vehicle with high-performance capabilities, you may require brake pads that can withstand the increased stress and heat generated by these vehicles. In this case, sintered brake pads may be the better choice due to their durability and heat resistance.

Additionally, it’s essential to consider the type of driving you’ll be doing most often. If you’ll be driving in mountainous terrain or towing a trailer, you may require brake pads that can withstand the increased stress and heat generated by these activities. In this case, sintered brake pads may be the better choice due to their durability and heat resistance.

By considering these factors and understanding the differences between sintered and ceramic brake pads, you can make an informed decision that meets your vehicle’s specific needs. In the next section, we will delve into the advantages and disadvantages of sintered brake pads, including their durability, heat resistance, and potential drawbacks such as noise and vibration.

Sintered Brake Pads: The Pros and Cons

Sintered brake pads are a popular choice among vehicle owners due to their durability and heat resistance. These brake pads are made using a process called sintering, where metal powders are compressed and heated to form a solid bond. This process creates a strong and durable brake pad that can withstand high temperatures and heavy use.

One of the main advantages of sintered brake pads is their durability. They are designed to last longer than ceramic brake pads and can withstand the rigors of heavy use. Additionally, sintered brake pads are highly resistant to heat, making them a great choice for vehicles that are driven in extreme temperatures.

Another benefit of sintered brake pads is their ability to provide consistent braking performance. They are designed to maintain their braking power even in high-temperature environments, making them a great choice for vehicles that are driven in stop-and-go traffic or in mountainous terrain.

However, sintered brake pads also have some drawbacks. One of the main disadvantages is their noise and vibration. Sintered brake pads can be noisy and can cause vibration when applied, which can be a problem for some vehicle owners. Additionally, sintered brake pads can be more expensive than ceramic brake pads, which can be a drawback for budget-conscious vehicle owners.

Despite these drawbacks, sintered brake pads are a great choice for vehicle owners who need a durable and heat-resistant brake pad. They are a popular choice among drivers who engage in heavy use, such as truck drivers or taxi drivers, and are also a great choice for vehicles that are driven in extreme temperatures.

In the next section, we will examine the benefits and drawbacks of ceramic brake pads, including their quiet operation, low dust production, and potential limitations such as reduced durability. By comparing the pros and cons of sintered and ceramic brake pads, vehicle owners can make an informed decision about which type of brake pad is right for their vehicle’s braking needs.

Ceramic Brake Pads: The Pros and Cons

Ceramic brake pads are a popular choice among vehicle owners due to their quiet operation and low dust production. These brake pads are made from a combination of ceramic fibers and other materials, which are designed to provide a smooth and quiet braking experience.

One of the main advantages of ceramic brake pads is their quiet operation. They are designed to reduce noise and vibration when applied, making them a great choice for vehicle owners who value a smooth and quiet ride. Additionally, ceramic brake pads produce less dust than sintered brake pads, which can be a benefit for vehicle owners who live in areas with high levels of air pollution.

Another benefit of ceramic brake pads is their low wear rate. They are designed to last longer than sintered brake pads and can withstand the rigors of heavy use. Additionally, ceramic brake pads are less likely to cause brake rotor wear, which can be a problem for some vehicle owners.

However, ceramic brake pads also have some drawbacks. One of the main disadvantages is their reduced durability. They are not as durable as sintered brake pads and can be more prone to wear and tear. Additionally, ceramic brake pads can be more expensive than sintered brake pads, which can be a drawback for budget-conscious vehicle owners.

Despite these drawbacks, ceramic brake pads are a great choice for vehicle owners who value a quiet and smooth braking experience. They are a popular choice among drivers who engage in light to moderate driving, such as commuters or families, and are also a great choice for vehicles that are driven in urban areas.

In the next section, we will compare the performance of sintered and ceramic brake pads in real-world scenarios, including stop-and-go traffic, highway driving, and extreme temperatures. By examining the pros and cons of each type of brake pad, vehicle owners can make an informed decision about which type of brake pad is right for their vehicle’s braking needs.

Real-World Comparison: Sintered vs Ceramic Brake Pads

In this section, we will compare the performance of sintered and ceramic brake pads in real-world scenarios, including stop-and-go traffic, highway driving, and extreme temperatures. By examining the pros and cons of each type of brake pad in different driving conditions, vehicle owners can make an informed decision about which type of brake pad is right for their vehicle’s braking needs.

Stop-and-Go Traffic: In stop-and-go traffic, ceramic brake pads tend to perform better than sintered brake pads. Ceramic brake pads are designed to provide a smooth and quiet braking experience, which is ideal for city driving. Sintered brake pads, on the other hand, can be noisy and produce more vibration in stop-and-go traffic.

Highway Driving: In highway driving, sintered brake pads tend to perform better than ceramic brake pads. Sintered brake pads are designed to provide excellent heat resistance and durability, which is ideal for high-speed driving. Ceramic brake pads, on the other hand, can be less effective in high-speed driving due to their reduced durability.

Extreme Temperatures: In extreme temperatures, sintered brake pads tend to perform better than ceramic brake pads. Sintered brake pads are designed to provide excellent heat resistance and durability, which is ideal for driving in extreme temperatures. Ceramic brake pads, on the other hand, can be less effective in extreme temperatures due to their reduced durability.

Overall, the performance of sintered and ceramic brake pads can vary depending on the driving conditions. Ceramic brake pads tend to perform better in city driving and low-speed conditions, while sintered brake pads tend to perform better in high-speed driving and extreme temperatures.

In the next section, we will review and compare popular sintered and ceramic brake pad products, including their features, pricing, and customer reviews. By examining the pros and cons of each product, vehicle owners can make an informed decision about which type of brake pad is right for their vehicle’s braking needs.

Product Review: Top Sintered and Ceramic Brake Pads on the Market

In this section, we will review and compare popular sintered and ceramic brake pad products, including their features, pricing, and customer reviews. By examining the pros and cons of each product, vehicle owners can make an informed decision about which type of brake pad is right for their vehicle’s braking needs.

Top Sintered Brake Pads:

Bosch Sintered Brake Pads: These brake pads are known for their excellent durability and heat resistance. They are designed to provide consistent braking performance and are suitable for high-performance vehicles.

Wagner Sintered Brake Pads: These brake pads are designed to provide excellent stopping power and are suitable for heavy-duty vehicles. They are also known for their quiet operation and low vibration.

Top Ceramic Brake Pads:

Ceramic Brake Pads by Akebono: These brake pads are known for their quiet operation and low dust production. They are designed to provide consistent braking performance and are suitable for passenger vehicles.

Ceramic Brake Pads by Raybestos: These brake pads are designed to provide excellent stopping power and are suitable for heavy-duty vehicles. They are also known for their durability and heat resistance.

Comparison of Sintered and Ceramic Brake Pads:

When comparing sintered and ceramic brake pads, it’s essential to consider the specific needs of your vehicle. Sintered brake pads are suitable for high-performance vehicles and provide excellent durability and heat resistance. Ceramic brake pads, on the other hand, are suitable for passenger vehicles and provide quiet operation and low dust production.

In the next section, we will provide guidance on proper installation and maintenance techniques for brake pads, including how to extend their lifespan and ensure optimal performance.

Installation and Maintenance: Tips for Getting the Most Out of Your Brake Pads

Proper installation and maintenance of brake pads are crucial to ensure optimal performance and extend their lifespan. In this section, we will provide guidance on how to install and maintain brake pads, including tips on how to get the most out of your sintered vs ceramic brake pads.

Installation Tips:

When installing brake pads, it’s essential to follow the manufacturer’s instructions and take necessary safety precautions. Make sure to clean the brake rotor and caliper before installing the new brake pads. Also, ensure that the brake pads are properly seated and aligned to avoid any uneven wear.

Maintenance Tips:

Regular maintenance is crucial to extend the lifespan of your brake pads. Check your brake pads regularly for wear and tear, and replace them when necessary. Also, make sure to clean your brake rotor and caliper regularly to prevent any debris from accumulating.

Tips for Extending the Lifespan of Your Brake Pads:

To extend the lifespan of your brake pads, it’s essential to drive safely and avoid aggressive driving habits. Avoid riding the brakes, as this can cause excessive wear on the brake pads. Also, make sure to check your brake fluid regularly and top it off as needed.

Conclusion:

In conclusion, proper installation and maintenance of brake pads are crucial to ensure optimal performance and extend their lifespan. By following the tips outlined in this section, you can get the most out of your sintered vs ceramic brake pads and ensure safe and reliable braking performance.

Conclusion: Sintered vs Ceramic Brake Pads – Which is Right for You?

In conclusion, the debate between sintered vs ceramic brake pads ultimately comes down to your specific needs and preferences. Both types of brake pads have their advantages and disadvantages, and it’s essential to consider these factors when making a decision.

Sintered brake pads are ideal for drivers who prioritize durability and heat resistance. They are suitable for high-performance vehicles and provide excellent stopping power in extreme temperatures. However, they can be noisy and produce more vibration than ceramic brake pads.

Ceramic brake pads, on the other hand, are ideal for drivers who prioritize quiet operation and low dust production. They are suitable for passenger vehicles and provide excellent braking performance in normal driving conditions. However, they may not be as durable as sintered brake pads and can be more expensive.

Ultimately, the decision between sintered and ceramic brake pads depends on your specific needs and preferences. By considering the factors outlined in this article, you can make an informed decision and choose the right brake pads for your vehicle.

Remember, brake pads are a critical component of your vehicle’s safety and performance. By choosing the right brake pads, you can ensure safe and reliable braking performance, and enjoy a smoother and more comfortable driving experience.