What Makes Steel Bike Frames an Attractive Choice?

Steel bike frames have long been a popular choice among cyclists due to their inherent strength, durability, and resilience. Their classic aesthetic appeal adds a touch of nostalgia and sophistication to any bicycle. However, traditional steel frames tend to be heavier than their modern counterparts, which can negatively impact performance and comfort. This is where the concept of lightweight steel bike frames comes into play, offering the best of both worlds.

The lightest steel bike frames combine the desirable properties of steel with a reduced weight, making them an attractive option for cyclists who seek the benefits of steel without the hefty weight penalty. These frames provide improved handling, acceleration, and climbing capabilities, all while maintaining the durability and classic appeal that steel is known for. By focusing on advanced materials, innovative designs, and cutting-edge manufacturing techniques, manufacturers are now able to produce lightweight steel bike frames that can compete with, and in some cases, outperform frames made from alternative materials.

How to Identify the Lightest Steel Bike Frames in the Market?

When searching for the lightest steel bike frames, there are several key factors to consider. These factors include frame weight, materials, and manufacturing techniques. By focusing on these aspects, you can ensure that you find a lightweight steel frame that meets your performance and comfort needs.

Frame Weight

Frame weight is an essential factor when evaluating lightweight steel bike frames. Generally, a lower frame weight translates to better performance, as it allows for easier acceleration, climbing, and handling. Look for frames that weigh between 3 and 5 pounds (1.36 to 2.27 kg) for optimal weight savings without sacrificing strength and durability.

Materials

The choice of materials plays a crucial role in determining the weight and strength of a steel bike frame. Advanced steel alloys, such as 4130 Chromoly, Scandium, and Maraging steel, are popular choices for lightweight frame designs due to their high strength-to-weight ratios. These alloys enable manufacturers to create frames that are both light and robust, ensuring long-lasting performance and resilience.

Manufacturing Techniques

Modern manufacturing techniques have significantly contributed to the development of lightweight steel bike frames. Techniques such as hydroforming, tubing manipulation, and TIG welding allow manufacturers to create frames with complex geometries and optimized shapes, further reducing weight without compromising strength and durability. Some brands known for their lightweight steel frames include Cinelli, Kestrel, and Ritchey, among others.

User Reviews and Testimonials

Lastly, consulting user reviews and testimonials can provide valuable insights into the performance and durability of lightweight steel bike frames. These first-hand accounts can help you make an informed decision based on the experiences of other cyclists, ensuring that you find a frame that meets your expectations and requirements.

The Role of Advanced Steel Alloys in Lightweight Frame DesignManufacturing Techniques for Lightweight Steel Bike Frames

Advanced manufacturing techniques play a crucial role in creating lightweight steel bike frames without compromising strength and durability. By leveraging these innovative methods, manufacturers can produce frames that offer enhanced performance and comfort while retaining the desirable properties of steel.

Hydroforming

Hydroforming is a manufacturing process that involves shaping metal tubes using high-pressure fluid. This technique allows for the creation of complex geometries and optimized shapes, resulting in lighter and stronger frames. Hydroforming can be applied to both frame tubes and various frame components, such as dropouts and bottom brackets, further reducing weight and enhancing overall frame performance.

Tubing Manipulation

Tubing manipulation is another essential technique for creating lightweight steel bike frames. By carefully manipulating the dimensions, shapes, and wall thicknesses of frame tubes, manufacturers can optimize the weight, stiffness, and strength of the frame. For instance, using thinner wall sections in areas where strength is not a primary concern, such as the top tube, can help reduce overall frame weight while maintaining structural integrity.

TIG Welding

Tungsten Inert Gas (TIG) welding is a precise welding technique that enables manufacturers to create strong and lightweight steel bike frames. TIG welding allows for the controlled heating and cooling of metal, minimizing the risk of warping and distortion. This results in a cleaner, stronger, and more aesthetically pleasing weld, which contributes to the overall strength and durability of the frame.

Butted Tubing

Butted tubing is a technique where the wall thickness of frame tubes is varied along their length. Thinner walls are used in areas where strength is not a primary concern, while thicker walls are employed in high-stress areas. This approach results in a lighter and stronger frame, as it optimizes the use of materials and reduces unnecessary weight.

Cold-Working Techniques

Cold-working techniques, such as cold-drawing and cold-rolling, can be used to further reduce the weight of steel bike frames. These processes involve deforming the metal at room temperature, which increases its strength and stiffness while reducing its thickness and weight. Cold-working techniques can be applied to various frame components, such as chainstays, seatstays, and fork blades, resulting in a lighter and more responsive frame.

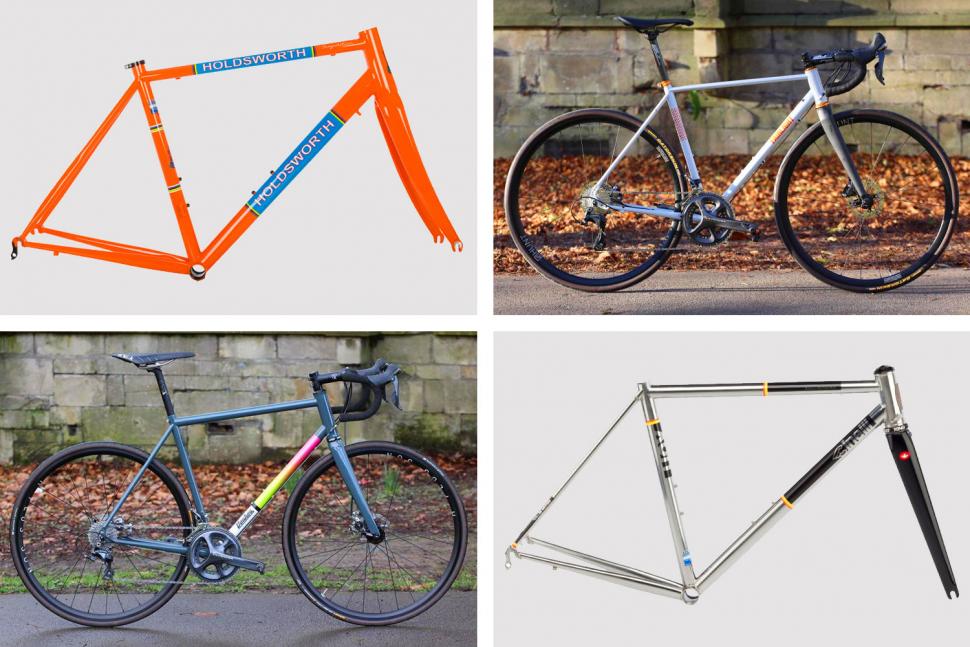

Popular Lightweight Steel Frame Models for Road and Mountain Bikes

When searching for the lightest steel bike frames, it’s essential to consider various options suitable for different cycling disciplines. Here, we present a selection of lightweight steel frame models suitable for road and mountain biking, detailing their features, benefits, and price ranges. User reviews and testimonials are included for added credibility.

Road Bike Frames

Breezer Doppler Pro: The Doppler Pro is a lightweight steel road bike frame made from custom-butted Reynolds 631 steel. It features a tapered head tube, thru-axles, and a threaded bottom bracket for improved stiffness and power transfer. The frame weighs approximately 3.6 lbs (1.63 kg) and is available for around $1,200.

User Review: “The Doppler Pro offers a fantastic balance of weight, strength, and comfort. I’ve been impressed with its performance and classic steel aesthetics.”

Mountain Bike Frames

Salsa Timberjack GX Eagle: The Timberjack GX Eagle is a versatile and lightweight steel mountain bike frame, constructed from 4130 Chromoly steel. It features a slack 66.5-degree head angle, 140mm of rear travel, and a 130mm fork, making it suitable for various trail conditions. The frame weighs around 5.5 lbs (2.49 kg) and retails for approximately $1,500.

User Testimonial: “The Timberjack GX Eagle has been a reliable and enjoyable trail companion. Its lightweight and robust steel frame has handled everything I’ve thrown at it.”

Additional Lightweight Steel Frame Models

Other notable lightweight steel frame models include the Kona Rove ST for gravel riding, the Surly Straggler for versatility, and the All-City Gorilla Monsoon for bikepacking adventures. Each of these frames offers a unique blend of weight savings, durability, and performance, making them excellent choices for cyclists seeking a lightweight steel bike frame.

Comparing Lightweight Steel Frames with Alternative Materials

When searching for the lightest steel bike frame, it’s essential to compare its properties with alternative materials, such as aluminum, titanium, and carbon fiber. Each material has its unique advantages and disadvantages in terms of weight, cost, durability, and performance. By understanding these differences, cyclists can make informed decisions about the best frame material for their needs.

Aluminum

Aluminum is a popular material for lightweight bike frames due to its low weight, corrosion resistance, and relatively low cost. Aluminum frames typically weigh between 3 and 5 lbs (1.36 and 2.27 kg), making them comparable to lightweight steel frames. However, aluminum can be less durable than steel, as it is more prone to fatigue and impact damage. Additionally, aluminum frames may have a harsher ride quality due to their lower stiffness-to-weight ratio compared to steel.

Titanium

Titanium is a high-performance material known for its exceptional strength, durability, and corrosion resistance. Titanium frames typically weigh between 3 and 5 lbs (1.36 and 2.27 kg), similar to lightweight steel and aluminum frames. However, titanium is more expensive than steel and aluminum, which can make it a less accessible option for some cyclists. Despite the higher cost, titanium frames offer a unique blend of lightweight, durability, and ride quality, making them a popular choice among enthusiasts.

Carbon Fiber

Carbon fiber is a cutting-edge material used in high-performance bike frames due to its unparalleled strength-to-weight ratio. Carbon fiber frames can weigh as little as 1.5 lbs (0.68 kg) for road bikes and 2.5 lbs (1.13 kg) for mountain bikes, making them significantly lighter than lightweight steel frames. However, carbon fiber frames can be more brittle than steel and may be more susceptible to impact damage. Additionally, carbon fiber frames tend to be more expensive than steel frames, which can be a barrier for some cyclists.

Selecting the Right Material

Ultimately, the choice of frame material depends on a cyclist’s personal preferences, budget, and performance goals. While carbon fiber frames offer the lowest weight and highest performance, they can also be more expensive and less durable than lightweight steel frames. Aluminum frames provide a cost-effective alternative to steel and carbon fiber, but they may have a harsher ride quality. Titanium frames offer a unique blend of lightweight, durability, and ride quality, but they come at a premium price. By understanding the advantages and disadvantages of each material, cyclists can make informed decisions about the best lightweight steel bike frame for their needs.

Maintaining and Upgrading Your Lightweight Steel Bike Frame

Maintaining and upgrading your lightweight steel bike frame is crucial for ensuring its longevity, performance, and aesthetic appeal. By following a few simple steps and incorporating innovative upgrades, cyclists can keep their lightweight steel bike frames in pristine condition and customize them to their preferences.

Cleaning and Protecting Your Frame

Regular cleaning is essential for preserving the appearance and performance of your lightweight steel bike frame. Use a mild detergent, warm water, and a soft-bristled brush to gently remove dirt, debris, and grime from the frame. After cleaning, rinse the frame thoroughly and dry it completely to prevent water spots and rust. To further protect your frame, consider applying a clear coat or wax to create a barrier against the elements.

Customizing Your Frame

Customizing your lightweight steel bike frame can be a fun and rewarding way to make it uniquely your own. Consider adding custom decals, paint jobs, or anodized components to enhance the frame’s appearance. Additionally, you can upgrade your components, such as wheels, drivetrain, or brakes, to improve the bike’s performance and create a personalized riding experience.

Retrofitting Older Steel Frames

Retrofitting older steel frames with modern lightweight components can be a cost-effective way to upgrade your bike without purchasing a new frame. Many older steel frames can accommodate modern components, such as thru-axles, disc brakes, and electronic drivetrains, providing improved performance and compatibility with contemporary cycling technology.

Selecting the Right Upgrades

When upgrading your lightweight steel bike frame, consider the following factors: compatibility, weight, durability, and performance. Ensure that the components you select are compatible with your frame, and consider the weight savings, durability, and performance enhancements they provide. By carefully selecting the right upgrades, you can create a customized, high-performance bike that meets your unique needs and preferences.

The Future of Lightweight Steel Bike Frames: Innovations and Trends

As the demand for lightweight and high-performance bicycles continues to grow, so does the innovation in materials, manufacturing techniques, and design for steel bike frames. By staying informed about emerging trends and innovations, cyclists can make more informed decisions about their next lightweight steel bike frame purchase.

Advancements in Steel Alloys

The development of advanced steel alloys, such as 4130 Chromoly, Scandium, and Maraging steel, has led to significant improvements in the strength-to-weight ratio of steel bike frames. These alloys enable manufacturers to create lighter and stronger frames without compromising durability or resilience. As research and development in steel alloys continue, we can expect to see even more lightweight and high-performance steel bike frames in the future.

Innovative Manufacturing Techniques

Innovative manufacturing techniques, such as 3D printing, continuous fiber manufacturing, and automated welding, are revolutionizing the way lightweight steel bike frames are produced. These advanced methods enable manufacturers to create complex shapes, optimize frame designs, and reduce material waste, ultimately leading to lighter, stronger, and more sustainable steel bike frames.

Design Trends

Design trends in lightweight steel bike frames are focusing on improved aerodynamics, increased stiffness, and enhanced rider comfort. By incorporating features such as dropped chainstays, asymmetrical frame designs, and integrated seatposts, manufacturers can create frames that not only look great but also perform exceptionally well. Additionally, the growing popularity of gravel and adventure biking has led to an increase in demand for lightweight steel frames that offer versatility, durability, and comfort on various terrains.

Sustainability and Recycling

As the cycling industry becomes more environmentally conscious, manufacturers are exploring ways to reduce the environmental impact of bicycle production. Steel, being one of the most recycled materials on the planet, is well-positioned to play a significant role in sustainable cycling practices. By utilizing recycled steel and implementing eco-friendly manufacturing processes, companies can create high-performance lightweight steel bike frames that contribute to a greener future.

Embracing the Future

The future of lightweight steel bike frames is bright, with innovative materials, manufacturing techniques, and design trends driving the industry forward. By staying informed about these advancements, cyclists can look forward to a new generation of lightweight, high-performance steel bike frames that offer unparalleled durability, resilience, and aesthetic appeal.